Trolley assembly annealing furnace

An annealing furnace and trolley-type technology are applied in the field of assembled combined annealing furnaces, which can solve the problems that the annealing furnace cannot adjust the furnace shape and heating space, the size and length of the furnace body cannot be easily changed, and the equipment cannot be adapted to different sizes. Shorten equipment manufacturing cycle, strong adaptability and good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] specific implementation plan

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] The present invention will be further described below in conjunction with accompanying drawing.

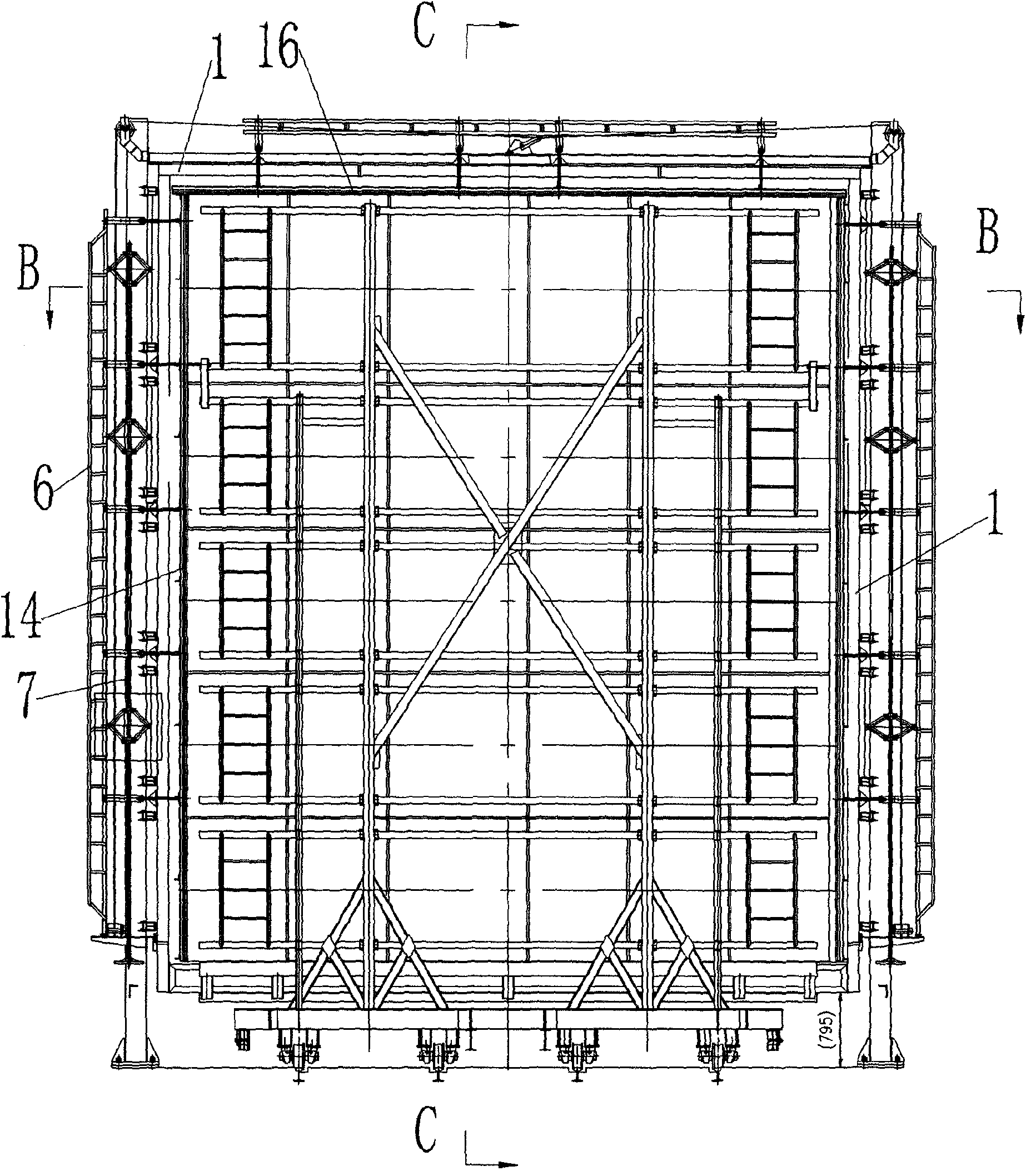

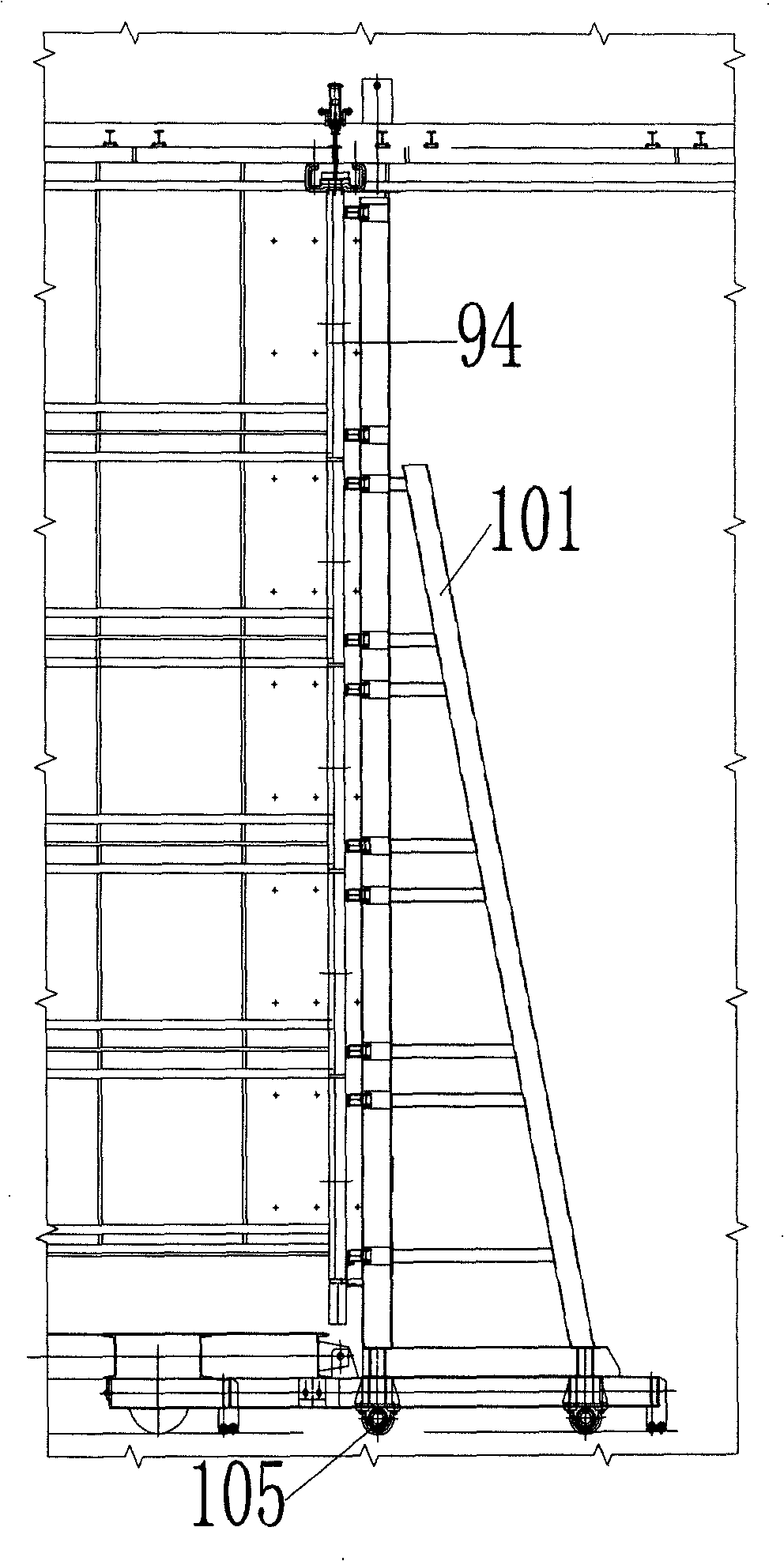

[0041] The present invention is mainly composed of seven parts: a combined furnace body; a movable combined trolley and an insulating lining; a mechanically lifted furnace door; a combined heat row; a movable wall (partition wall) for thermal insulation in the furnace; system; furnace temperature electronic computer PID adjustment automation control part, etc.

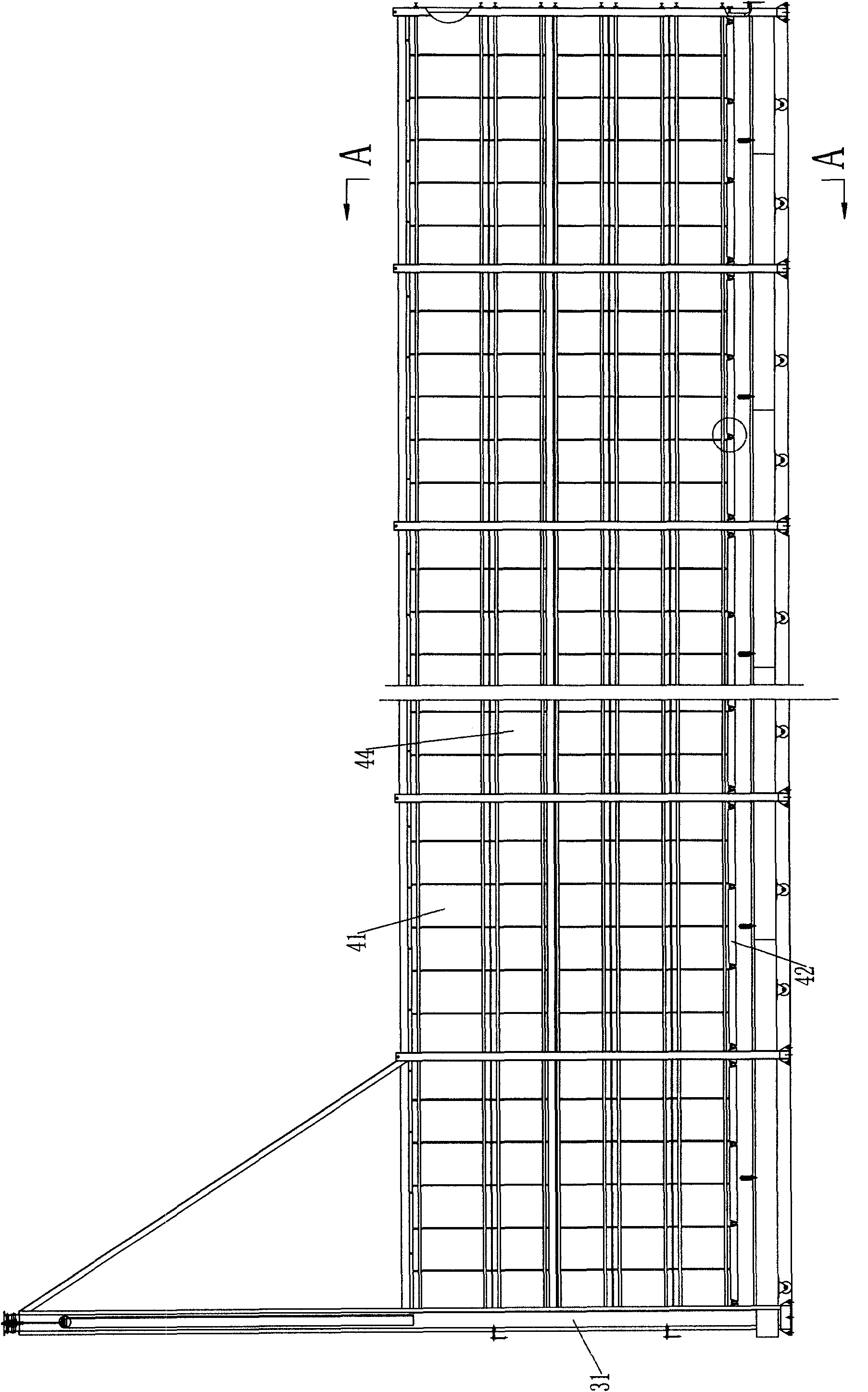

[0042] see figure 1 , the frame of the whole annealing furnace is a steel structure frame, and the furnace door frame 31 and the side column of the furnace body are fixed to the ground through anchor bolts, etc., and then connected into a solid whole by some section steels, tie rods, etc. In addition to the steel structure, the entir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com