Coating drying solidifying forced convection heating furnace with suspending conveying workpiece device

A technology of forced convection and heating furnace, which is applied in the direction of heating devices, progressive dryers, lighting and heating equipment, etc., which can solve the problem of serious flow heat loss and achieve the effect of saving heating energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

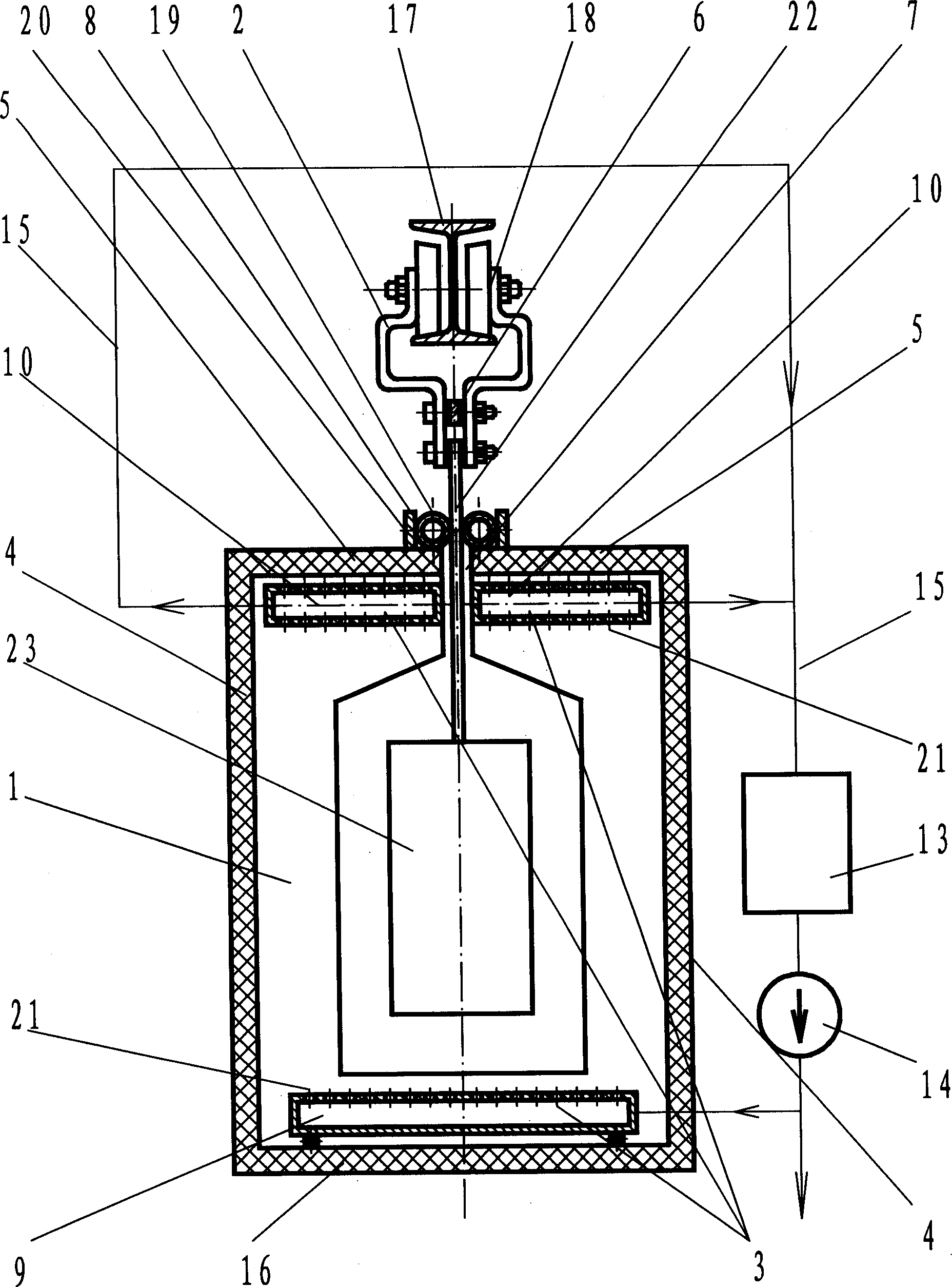

[0020] as attached figure 1 As shown, this embodiment mainly includes a heating furnace 1, a suspension conveying device 2, a forced convection device 3 in the furnace, a hot blast stove 13, a circulating fan 14, a circulating air duct 15, and an opening seam shielding device 8. The heating furnace is surrounded by the furnace side wall 4, the furnace bottom 16 and the furnace roof wall 5. There is a longitudinal continuous opening 7 in the center of the furnace roof 5. The width of the continuous opening 7 is 30 mm; the opening slit shielding device 8 is provided On the outside of the furnace roof wall, on both sides of the continuous opening slit 7, it mainly includes the canvas tube 19 positioned at both sides of the opening slit 7 and the limit baffle 20 fixed on the outside of the canvas tube 19, the canvas tube is filled with water, and the canvas tube The diameter is 100mm, and the distance between the opposite surfaces of the two limit baffles is 190mm; the forced conv...

Embodiment 2

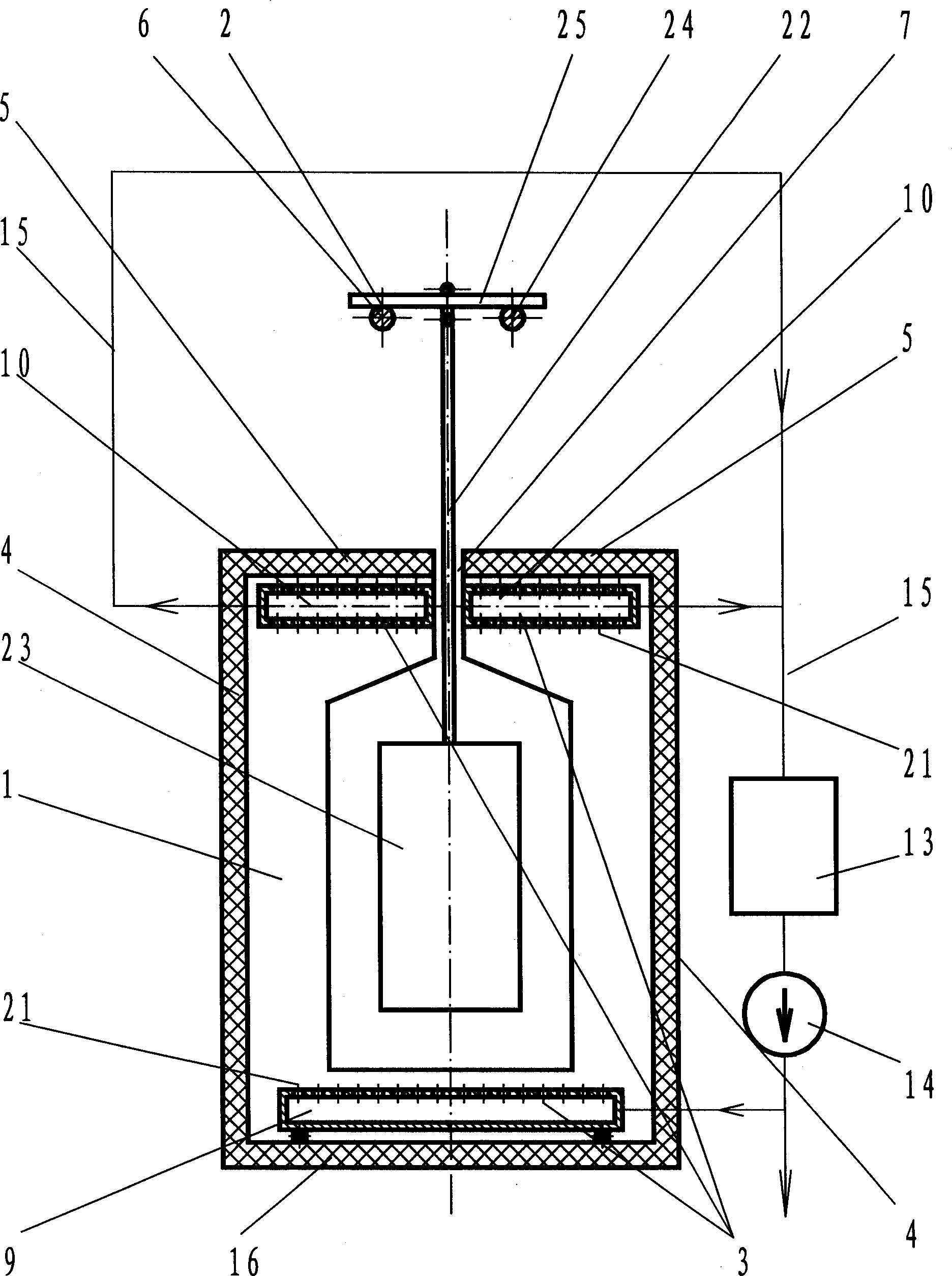

[0022] as attached figure 2 As shown, this embodiment is basically the same as Embodiment 1, with two points of difference: the first point is that there is no opening seam shielding device; Bars are on the same horizontal plane and parallel steel wire ropes 24 and cross bars 25 fixed on the two steel wire ropes 24. The cross bar 25 is perpendicular to the steel wire ropes 24, and a cross bar 25 is fixed every certain distance along the length direction of the steel wire ropes.

Embodiment 3

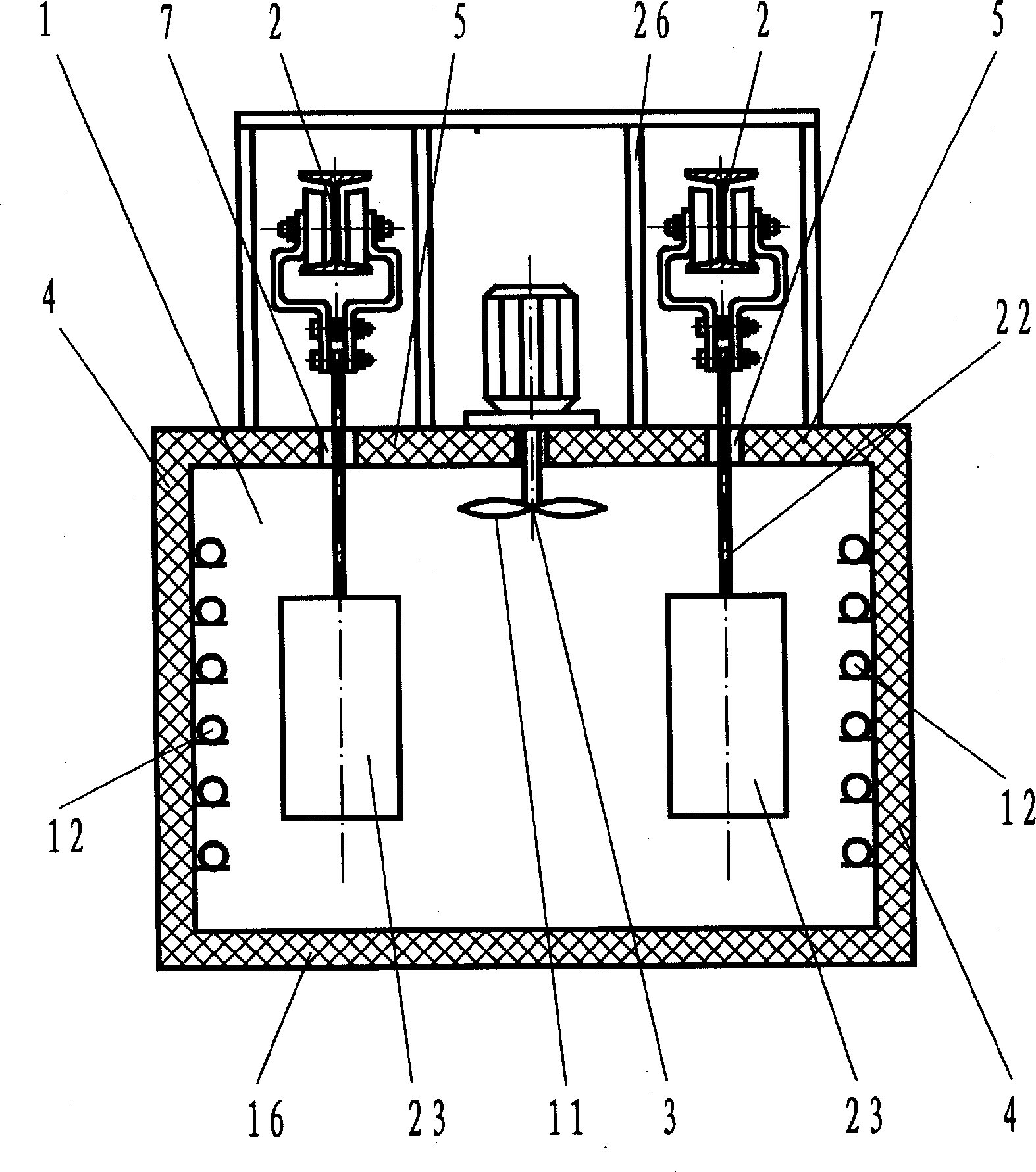

[0024] as attached image 3 , attached Figure 4 As shown, this embodiment mainly includes a heating furnace 1, a suspension conveying device 2 and a forced convection device 3 in the furnace; Located at the same end; the heating furnace is surrounded by the furnace side wall 4, the furnace bottom 16 and the furnace roof wall 5. There is a "U"-shaped continuous opening 7 in the center of the furnace roof 5. The width of the continuous opening 7 is 25mm and parallel to the conveying track in the suspension conveying device, the furnace roof wall in the middle part is completely suspended and fixed by the support 26; the forced convection device 3 in the heating furnace is mainly several forced convection fans 11 located above the furnace; A number of regularly distributed electric heating tubes 12 are arranged on the inner surface of the furnace side wall 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com