Fire hose material with flame-retardant and acid-base-resistant functions

A fire hose, acid and alkali resistant technology, applied in the field of fire hose materials, can solve problems such as fire hose damage by heat, achieve superior flame retardancy and improve product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

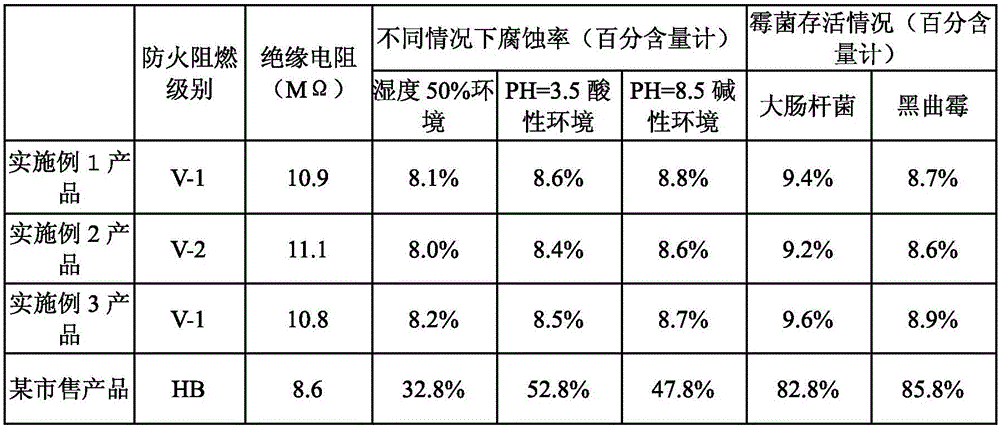

Embodiment 1

[0016] The fire hose material with flame retardant acid and alkali resistance function in this embodiment is composed of the following components in parts by mass: 22 parts of neoprene rubber, 20 parts of hydrogenated rosin, 20 parts of melamine formaldehyde resin, cellulose acetate butyrate 18 parts, PCB 20 parts, ammonium polyphosphate 20 parts, pyromellitic dianhydride 18 parts, piperine 20 parts, sulfonic acid 20 parts, chitin 18 parts, polyhexamethylene guanidine 18 parts, poly 18 parts of hexamethylene biguanide hydrochloride, 20 parts of alum stone powder, 18 parts of wood pulp, 16 parts of calcium lignosulfonate, 20 parts of nano aluminum nitride powder, 18 parts of nano aluminum powder, 16 parts of nano zirconia powder, 18 parts of nano-nickel oxide, 16 parts of polyacrylate emulsion, 16 parts of polypropylene glycol, 18 parts of polyglycerin, 18 parts of polylactic acid, 18 parts of polyepoxysuccinic acid, 18 parts of polyetheretherketone fiber, polycarboxylic acid 1...

Embodiment 2

[0022] The fire hose material with flame retardant acid and alkali resistance function in this embodiment is composed of the following components in parts by mass: 24 parts of neoprene rubber, 22 parts of hydrogenated rosin, 22 parts of melamine formaldehyde resin, cellulose acetate butyrate 20 parts, PCB 22 parts, ammonium polyphosphate 22 parts, pyromellitic dianhydride 20 parts, piperine 22 parts, sulfonic acid 22 parts, chitin 20 parts, polyhexamethylene guanidine 20 parts, poly 20 parts of hexamethylene biguanide hydrochloride, 22 parts of alum stone powder, 20 parts of wood pulp, 18 parts of calcium lignosulfonate, 22 parts of nano aluminum nitride powder, 20 parts of nano aluminum powder, 18 parts of nano zirconia powder, 20 parts of nano-nickel oxide, 18 parts of polyacrylate emulsion, 18 parts of polypropylene glycol, 20 parts of polyglycerin, 20 parts of polylactic acid, 20 parts of polyepoxysuccinic acid, 20 parts of polyether ether ketone fiber, polycarboxylic acid ...

Embodiment 3

[0028] The fire hose material with flame retardant acid and alkali resistance function in this embodiment is composed of the following components in parts by mass: 26 parts of neoprene rubber, 24 parts of hydrogenated rosin, 24 parts of melamine formaldehyde resin, cellulose acetate butyrate 22 parts, PCB 24 parts, ammonium polyphosphate 24 parts, pyromellitic dianhydride 22 parts, piperine 24 parts, sulfonic acid 24 parts, chitin 22 parts, polyhexamethylene guanidine 22 parts, poly 22 parts of hexamethylene biguanide hydrochloride, 24 parts of alum stone powder, 22 parts of wood pulp, 20 parts of calcium lignosulfonate, 24 parts of nano aluminum nitride powder, 22 parts of nano aluminum powder, 20 parts of nano zirconia powder, 22 parts of nano-nickel oxide, 20 parts of polyacrylate emulsion, 20 parts of polypropylene glycol, 22 parts of polyglycerin, 22 parts of polylactic acid, 22 parts of polyepoxysuccinic acid, 22 parts of polyetheretherketone fiber, polycarboxylic acid 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com