Environment-friendly flame-retardant acid- and alkali-resistant treating coating for building materials

A building material, acid and alkali resistance technology, used in coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve the problems of difficult absorption, poor sound absorption performance, etc., to achieve superior flame retardant and improve product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

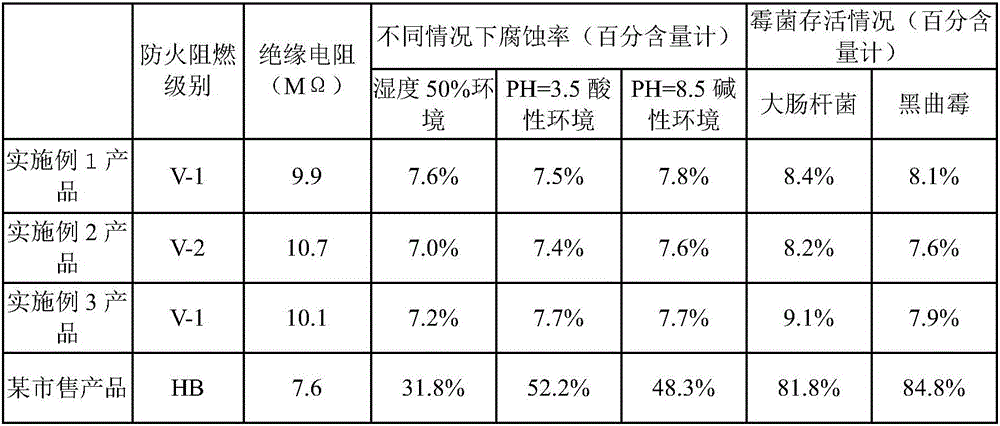

Embodiment 1

[0016] The environmental-friendly, flame-retardant, acid- and alkali-resistant treatment coating for building materials in this embodiment consists of the following components in parts by mass: 24 parts of methyl etherified amino resin, 22 parts of heat vulcanized silicone rubber, brominated diphenolic propane epoxy 22 parts of resin, 20 parts of wintergreen oil, 22 parts of walnut oil, 22 parts of orange oil, 20 parts of rose essential oil, 22 parts of lemon oil, 22 parts of stearamidopropyl pyrrolidone methyl dimethyl ammonium chloride, 20 parts of nano silver 20 parts of penicillin, 20 parts of deacetylated chitin, 22 parts of lead difluoride powder, 20 parts of titanium dioxide powder, 18 parts of fly ash, 22 parts of aluminum fluoride powder, 20 parts of corundum powder, 18 parts of zircon powder , 20 parts of wollastonite powder, 18 parts of zirconium silicate powder, 18 parts of nano zinc oxide, 18 parts of tri(butoxyethyl) phosphate, 16 parts of hexabromobenzene, 12 par...

Embodiment 2

[0022] The environmental protection, flame retardant, acid and alkali resistant treatment coating for building materials in this embodiment consists of the following components in parts by mass: 26 parts of methyl etherified amino resin, 24 parts of heat vulcanized silicone rubber, brominated diphenolic propane epoxy 24 parts of resin, 22 parts of wintergreen oil, 24 parts of walnut oil, 24 parts of orange oil, 22 parts of rose essential oil, 24 parts of lemon oil, 24 parts of stearamidopropyl pyrrolidone methyl dimethyl ammonium chloride, 22 parts of nano silver 22 parts of penicillin, 22 parts of chitin, 24 parts of lead difluoride powder, 22 parts of titanium dioxide powder, 20 parts of fly ash, 24 parts of aluminum fluoride powder, 22 parts of corundum powder, 20 parts of zircon powder , 22 parts of wollastonite powder, 20 parts of zirconium silicate powder, 20 parts of nano zinc oxide, 20 parts of tri(butoxyethyl) phosphate, 18 parts of hexabromobenzene, 14 parts of sodium...

Embodiment 3

[0028] The environmental protection, flame retardant, acid and alkali resistant treatment coating for building materials in this embodiment consists of the following components in parts by mass: 28 parts of methyl etherified amino resin, 26 parts of heat vulcanized silicone rubber, brominated diphenolic propane epoxy 26 parts of resin, 24 parts of wintergreen oil, 26 parts of walnut oil, 26 parts of orange oil, 24 parts of rose essential oil, 26 parts of lemon oil, 26 parts of stearamidopropyl pyrrolidone methyl dimethyl ammonium chloride, 24 parts of nano silver 24 parts of penicillin, 24 parts of deacetylated chitin, 26 parts of lead difluoride powder, 24 parts of titanium dioxide powder, 22 parts of fly ash, 26 parts of aluminum fluoride powder, 24 parts of corundum powder, 22 parts of zircon powder , 24 parts of wollastonite powder, 22 parts of zirconium silicate powder, 22 parts of nano zinc oxide, 22 parts of tri(butoxyethyl) phosphate, 20 parts of hexabromobenzene, 16 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com