Nano-crystalline cellulose/layered double hydroxide composite membrane and preparation method

A layered bimetal, nanocellulose technology, applied in the field of composite materials, can solve the problems of NCC film porous and flammable, high-performance material limitations, etc., and achieve the effects of controllable thickness and performance, low cost, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

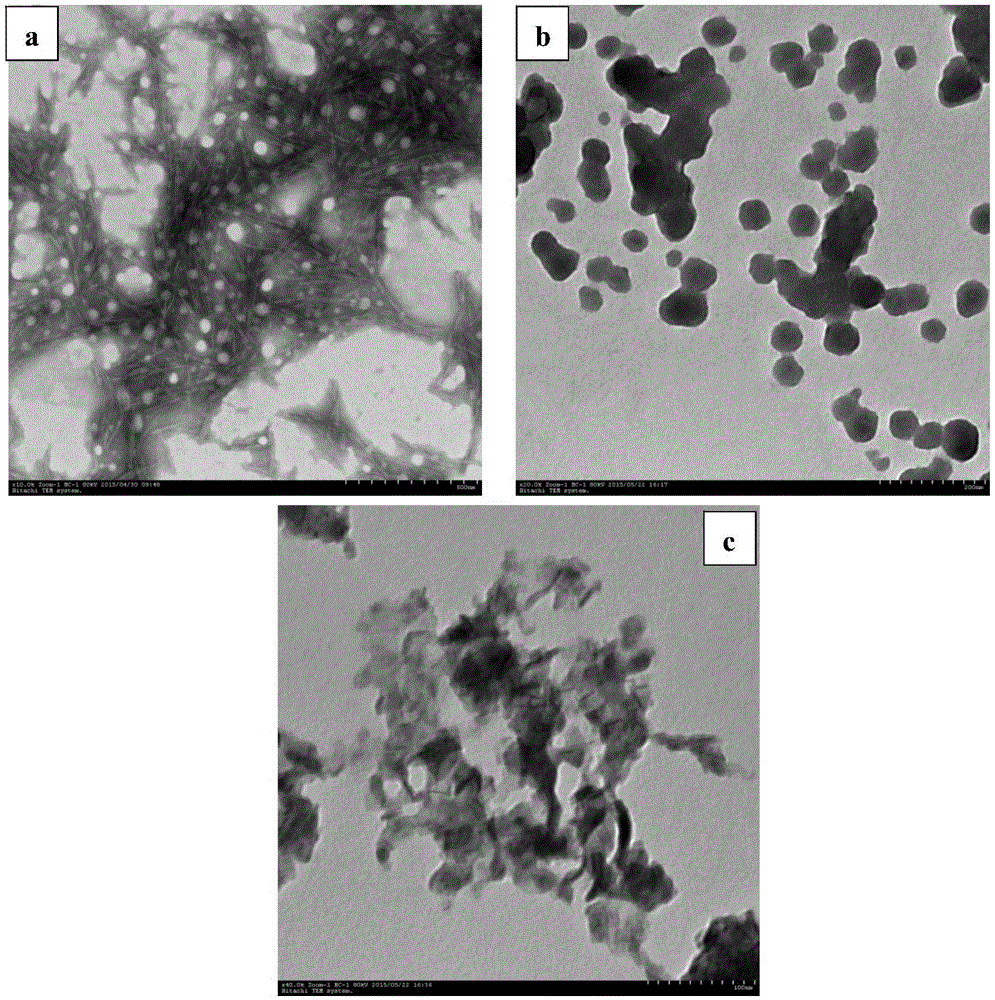

[0029] (1) Preparation of NCC dispersion with negative charge on the surface.

[0030] Negatively charged NCC on the surface obtained by hydrolyzing cotton linters with sulfuric acid was dispersed in water and then ultrasonicated for 20 min to obtain a dispersion with a concentration of 0.1%.

[0031] (2) Preparation of positively charged exfoliated LDH dispersion.

[0032] The positively charged LDH stripping solution obtained by stripping in formamide solution (raw material is Mg-AlLDH, purchased from Beijing Tecleer Technology Co., Ltd.) was added with water and then ultrasonicated for 20 minutes to obtain a dispersion with a concentration of 0.05%.

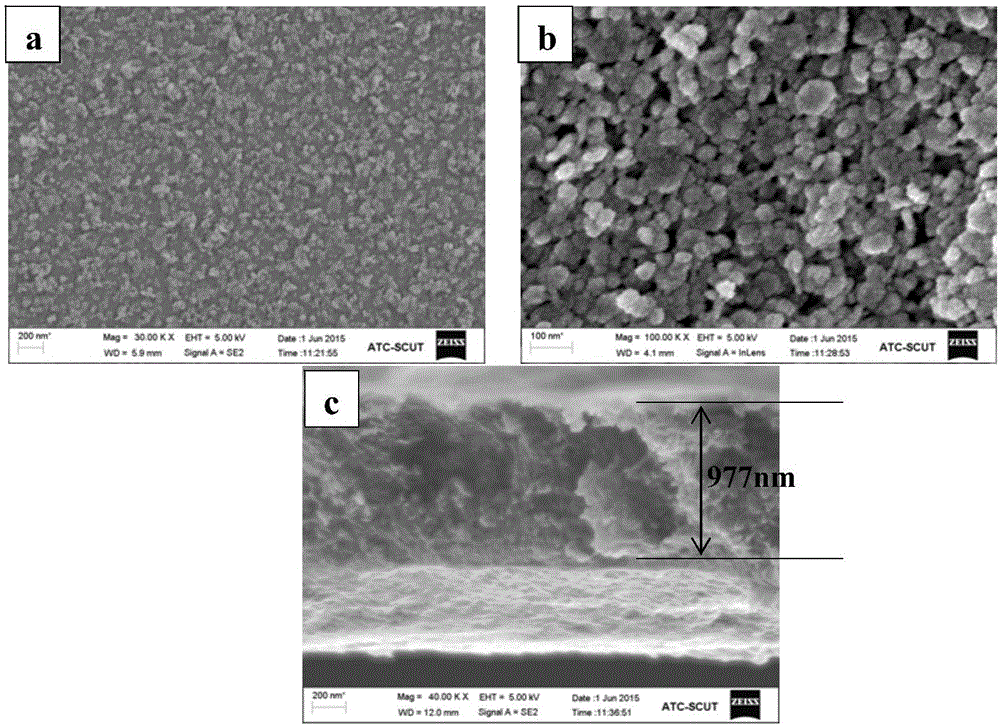

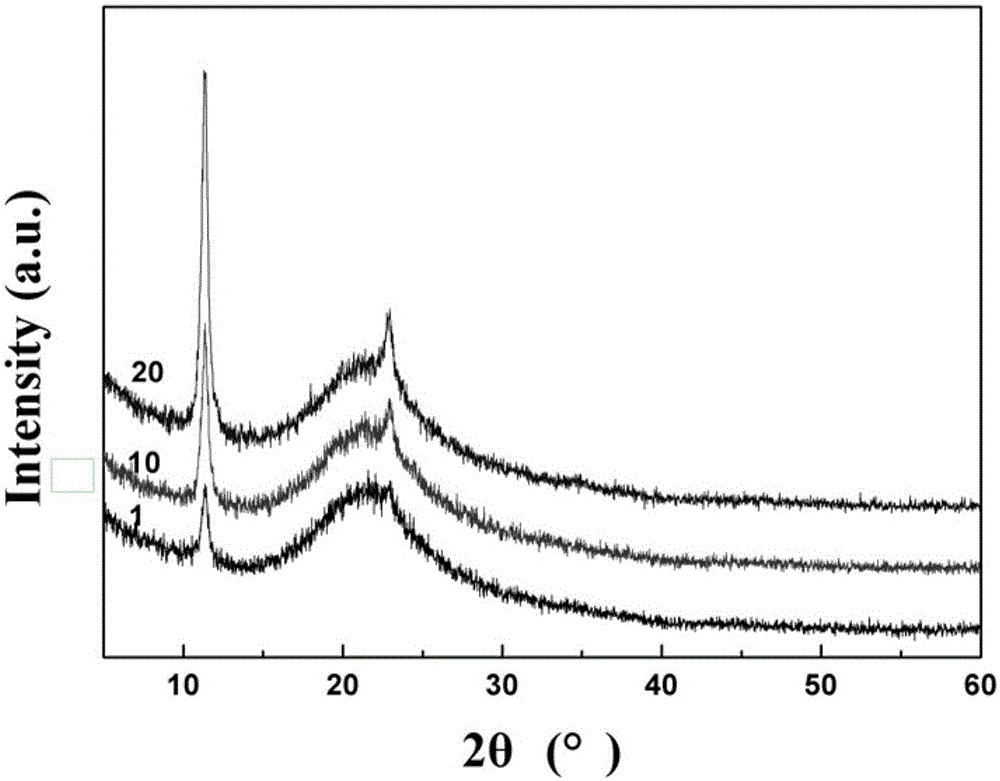

[0033] (3) Preparation of nanocellulose / layered double metal hydroxide (NCC / LDH) composite membrane.

[0034] The treated quartz substrate is immersed in LDH solution, taken out after 20 minutes, rinsed and dried, then immersed in NCC solution, taken out after 20 minutes, washed and dried. By repeating this 80 times, a multi...

Embodiment 2

[0036] (1) Preparation of NCC dispersion with negative charge on the surface.

[0037] Negatively charged NCC on the surface obtained by oxidizing bleached wood pulp with persulfate was dispersed in water and then ultrasonicated for 20 min to obtain a dispersion with a concentration of 0.1%.

[0038] (2) Preparation of positively charged exfoliated LDH dispersion.

[0039] The positively charged LDH stripping solution obtained by stripping in formamide solution (the raw material is Ni-AlLDH, purchased from Beijing Tecleer Technology Co., Ltd.) was added with water and then ultrasonicated for 20 minutes to obtain a dispersion with a concentration of 0.05%.

[0040] (3) Preparation of nanocellulose / layered double metal hydroxide (NCC / LDH) composite membrane.

[0041]The treated quartz substrate is immersed in LDH solution, taken out after 20 minutes, rinsed and dried, then immersed in NCC solution, taken out after 20 minutes, washed and dried. By repeating this 80 times, a mul...

Embodiment 3

[0043] (1) Preparation of NCC dispersion with negative charge on the surface.

[0044] Negatively charged NCC on the surface obtained by hydrolyzing waste paper pulp with sulfuric acid was dispersed in water and then ultrasonicated for 20 min to obtain a dispersion with a concentration of 0.1%.

[0045] (2) Preparation of positively charged exfoliated LDH dispersion.

[0046] The positively charged LDH stripping solution obtained by stripping in formamide solution (the raw material is Zn-AlLDH, purchased from Beijing Tecleer Technology Co., Ltd.) was added with water and then ultrasonicated for 30 minutes to obtain a dispersion with a concentration of 0.05%.

[0047] (3) Preparation of nanocellulose / layered double metal hydroxide (NCC / LDH) composite membrane.

[0048] The treated quartz substrate is immersed in LDH solution, taken out after 20 minutes, rinsed and dried, then immersed in NCC solution, taken out after 20 minutes, washed and dried. By repeating this 100 times, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com