Mold structure and motor

A structure and molding technology, applied in other household appliances, coatings, winding insulation materials, etc., can solve the problems of high epoxy resin viscosity, inability to make molded structures, and electromagnetic coil molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach )

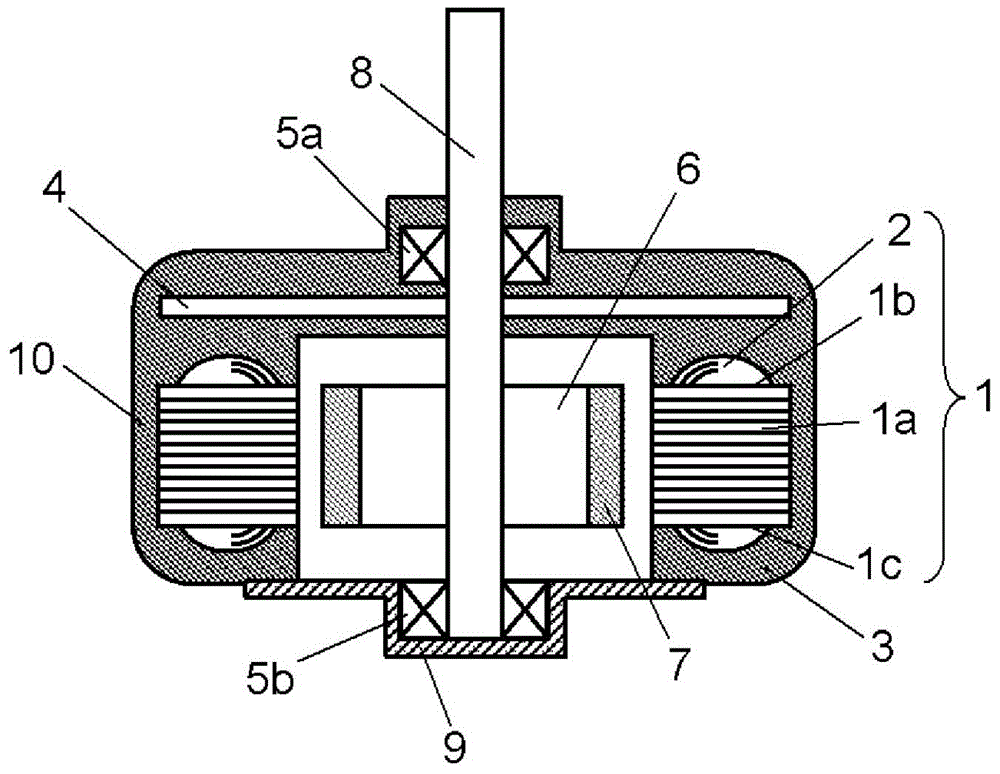

[0025] Hereinafter, for the molded structure in the embodiment of the present invention, use figure 1 Be explained. It should be noted, figure 1 In this section, a motor for home appliances such as a small air conditioner motor is described as an example. The motor is a molded structure obtained by molding an electromagnetic coil wound around an iron core using a molding resin. Forming.

[0026] figure 1 It is a sectional view showing the structure of the motor in the embodiment of the present invention.

[0027] like figure 1 As shown, the motor is composed of a stator 1, a drive circuit 4, and a rotor 6 with permanent magnets 7 on its outer periphery. The stator 1 of the motor is formed by winding a winding 2 through a bobbin in an iron core 1a; the part other than the inner peripheral surface of the iron core 1a is surrounded by a molded structure 3 formed of a molding resin. way integrally molded. At this time, the bearing housing for accommodating the bearing 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com