Graphene reinforced polyketone fiber and preparation method thereof

A graphene and polyketone technology, applied in fiber processing, fiber chemical characteristics, stretch spinning, etc., can solve problems such as failure to prepare fibers, improve melt processability, improve crystallinity and crystal regularity , the effect of prolonging the required time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

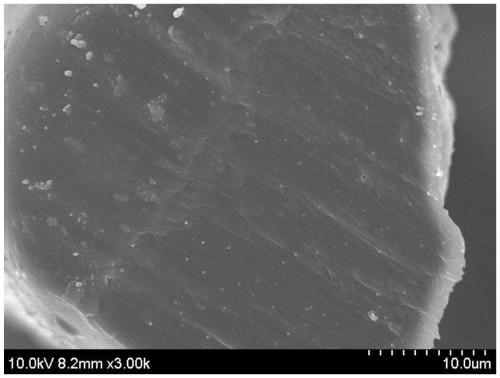

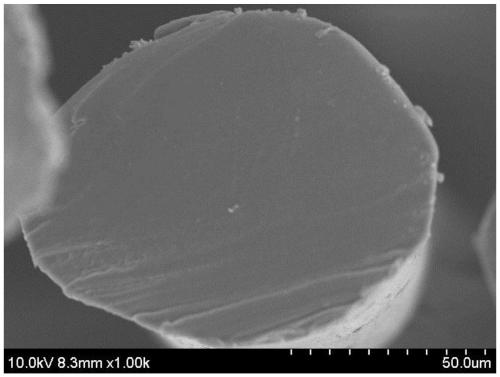

Image

Examples

preparation example Construction

[0022] The present invention provides a method for preparing graphene-reinforced polyketone fiber (method for short), which is characterized in that the method includes the following steps:

[0023] (1) The graphene and the surface treatment agent are mixed in a high-speed mixer at a high speed of 1000-5000rpm for 10-30 minutes until uniform; then the polyketone pellets are added to the high-speed mixer and continue to mix for 10-30 minutes until uniform, to obtain graphite Ene / polyketone mixture;

[0024] In the graphene / polyketone mixture, the graphene and the surface treatment agent are 0.05-2 mass parts, the polyketone is 98.0-99.95 mass parts, and the mass of the surface treatment agent is 10-30% of the graphene mass;

[0025] The graphene adopts graphene, graphene oxide, hydroxylated graphene, or carboxyl group with a radial dimension of nanometer or submicrometer (100nm-3μm), single-layer or few-layer (1-3 layers), and moisture content of less than 60ppm. Graphene;

[0026] Th...

Embodiment 1

[0035] (1) 0.2 parts by mass of 1-3 layers of graphene oxide with an average radial size of 1 μm is mixed with a mixture of 0.06 parts by mass of sodium dodecylbenzene sulfonate and 0.94 parts by mass of absolute ethanol and mixed at high speed Treated at 2000rpm in the machine for 20 minutes until uniform; then mixed with 99.74 parts by mass of polyketone resin (melt index 40g / 10min, propylene molar content is 6% of the total molar content of ethylene, carbon monoxide and propylene) and then mixed in a high-speed mixer Treat it at 2000 rpm for 20 minutes until it is uniform, let it stand for 30 minutes, take it out, and dry it under vacuum until the moisture content is less than 60 ppm;

[0036] (2) Into a single screw extruder with a diameter of 25mm, the temperature of the first to fourth areas of the screw are set to 180, 210, 230, and 230℃ respectively, the temperature of the elbow is 230℃, the temperature of the pump seat is 230℃, and the diameter of the spinneret hole 0.25...

Embodiment 2

[0040] (1) Using 1 to 3 layers of carboxylated graphene with an average radial size of 100 nm (carboxylated carbon atoms account for 4% of all carbon atoms) 0.05 parts by mass, and 0.01 parts by mass of 1-naphthoic acid and 0.99 parts by mass The mixture of parts of acetone is mixed in a high-speed mixer at 1800 rpm for 20 minutes to be uniform; then with 99.94 parts by mass of polyketone resin (melt index 20g / 10min, the molar content of propylene is the total molar content of ethylene, carbon monoxide and propylene 3%) after mixing in a high-speed mixer at 2000 rpm for 20 minutes until uniform, standing for 30 minutes and then taking it out, vacuum drying until the moisture content is less than 60 ppm;

[0041] (2) Into a single screw extruder with a diameter of 25mm, the temperature of zone 1 to zone 4 of the screw is set to 190, 220, 239, 239℃, the temperature of the elbow is 239℃, the temperature of the pump seat is 239℃, and the diameter of the spinneret hole 0.25mm, 96 hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com