Patents

Literature

44results about How to "Reduce balance torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite heat stabilizer for hydrophobic nano-hydrotalcite PVC and preparation method thereof

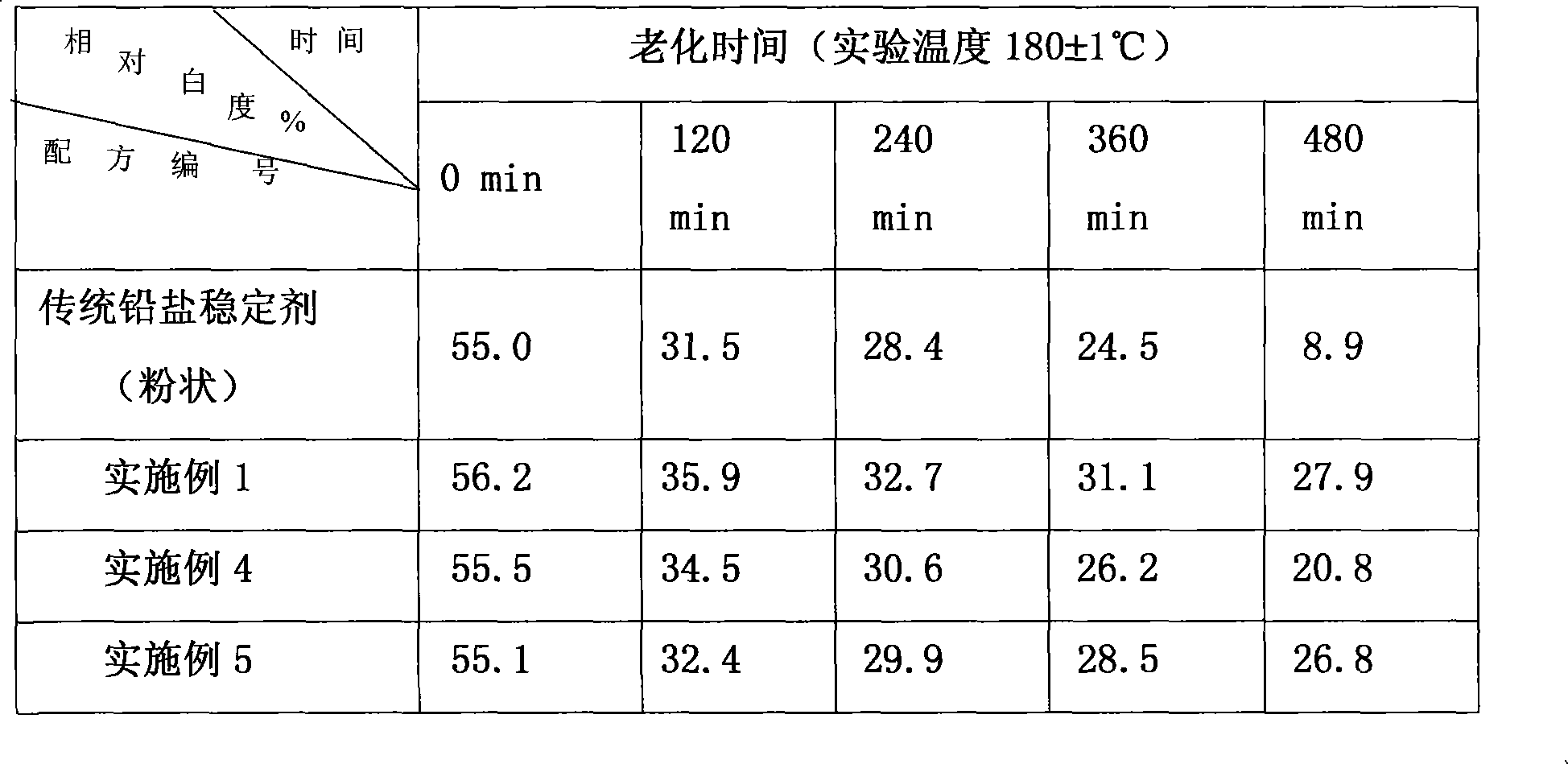

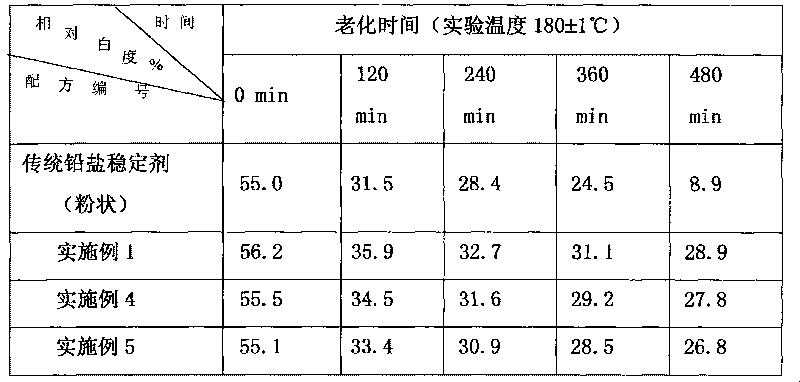

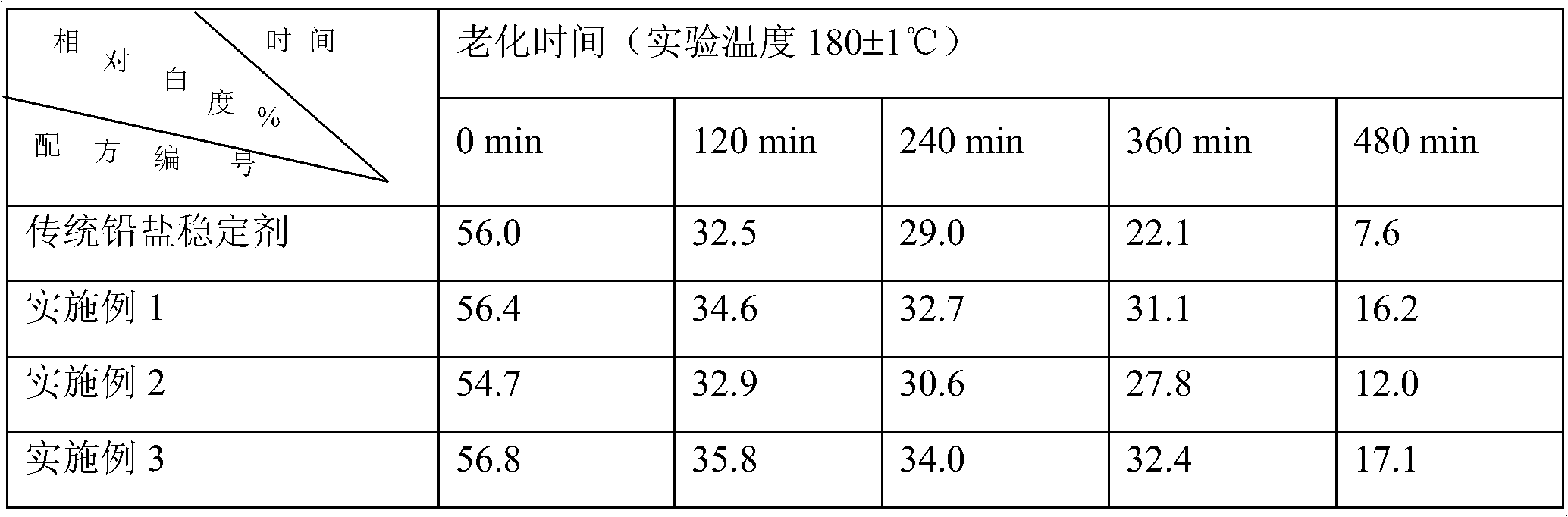

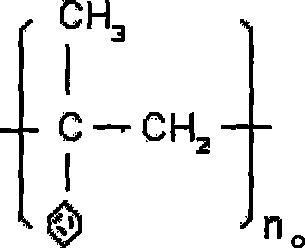

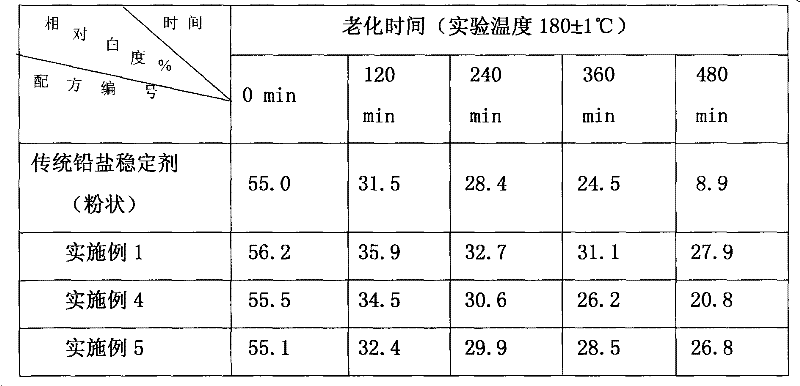

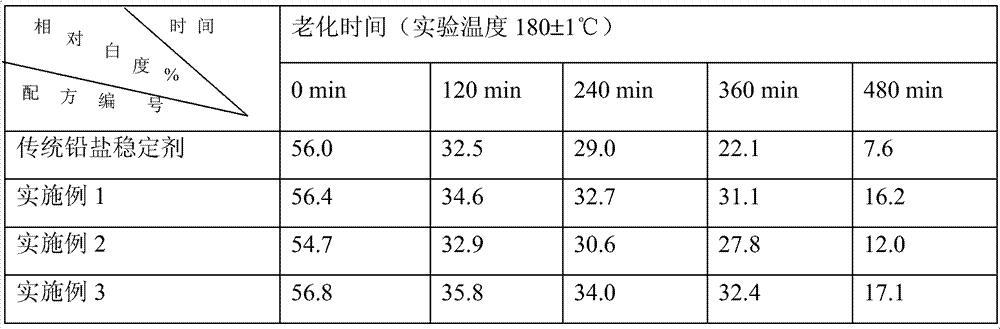

The invention relates to a composite heat stabilizer for hydrophobic nano-hydrotalcite PVC, comprising the following raw materials according to the mass percent: 30-50 of calcium stearate, 10-20 of zinc stearate, 10-30 of hydrophobic nano-hydrotalcite, 5-15 of lubricant, 4-7 of surface modifier and 5-15 of auxiliary heat stabilizer. With the method of coprecipitation, the hydrophobic nano-hydrotalcite is added with eunatrol to prepare hydrophobic nano-hydrotalcite including Mg and Al with the mol ratio of 2-3:1. The nano-hydrotalcite prepared by the invention has good hydrophobic nature. Good compatibility with a PVC basal body can be achieved if the nano-hydrotalcite is used in a composite heat stabilizer for PVC. Advantages of difficult precipitation and good stabilizing effect can be achieved when the nano-hydrotalcite is used as a stabilizer for plastic processing of PVC, and the like. The addition of the hydrophobic nano-hydrotalcite can reduce the balance torque, improve the processing property and reduce the cost. The preparation method causes no pollution and has low energy consumption.

Owner:慧科高新科技股份有限公司

High weather-proof, multiple-effect, environmentally-friendly PVC composite heat stabilizer and preparation method thereof

InactiveCN101735532AImprove hydrophobicityGood miscibilityOxygen/ozone/oxide/hydroxidePolymer sciencePolyethylene glycol

The invention discloses a high weather-proof, multiple-effect, environmentally-friendly PVC composite heat stabilizer which is composed of the following raw materials in percentage by weight: 20-40% of calcium stearate, 15-25% of zinc stearate, 10-30% of hydrophobicity nano-hydrotalcite, 1-1.5% of hyperdispersant, 5-15% of lubricating agent, 4-7% of surface modifier and 5-15% of assistant heat stabilizer, wherein, hydrophobicity nano-hydrotalcite is prepared with a coprecipitation method by adding sodium oleate, and the molar ratio of Mg to AL in hydrophobicity nano-hydrotalcite is 2-3:1; the hyperdispersant is copolymer of maleic anhydride-sodium allyl sulfonate-crylic acid polyethylene glycol monoester. The nano-hydrotalcite prepared by the invention has better hydrophobic property and favorable compatibility with PVC matrix. Hydrophobicity nano-hydrotalcite and hyperdispersant are added to lower balancing torque, improve handling characteristics and weather resistance and lower cost. The preparation method of the invention has no pollution and low energy consumption.

Owner:慧科高新科技股份有限公司

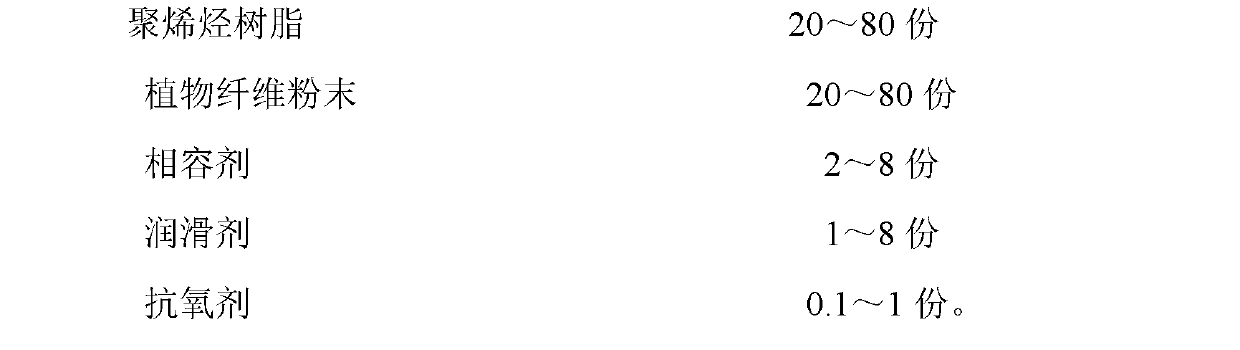

Polyolefin wood-plastic composite material and preparation method thereof

The invention discloses a polyolefin wood-plastic composite material. The polyolefin wood-plastic composite material is prepared by blending and extruding the following components in parts by weight: 20 to 80 parts of polyolefin resin, 20 to 80 parts of plant fiber powder, 2 to 8 parts of compatilizer, 1 to 8 parts of lubricant, and 0.1 to 1 part of antioxygen, wherein the lubricant includes pentaerythritol tetra-benzoate. The composite material has the balance torque of 3.2 to 8.4N.M, bending strength of 30.1 to 66.3MPa, and bending modulus of (0.80-22.6)*10<4>MPa. The invention also discloses a preparation method of the polyolefin wood-plastic composite material. The ester bond of the pentaerythritol tetra-benzoate contained in the wood-plastic composite material and the hydroxyl of the plant fibers can produce high hydrogen bond effect, so that the plant fibers can be promoted to be uniformly dispersed, the filling amount can be increased, the product cost is reduced, the defect on the appearance of the product is avoided, the melting and extruding efficiency is improved, and the bending performance and water absorbing performance of the material are improved; and the polyolefin wood-plastic composite material can be used as the high-level polyolefin wood-plastic composite material to be widely applied in the fields such as indoor and outdoor decoration and construction industry.

Owner:SICHUAN UNIV

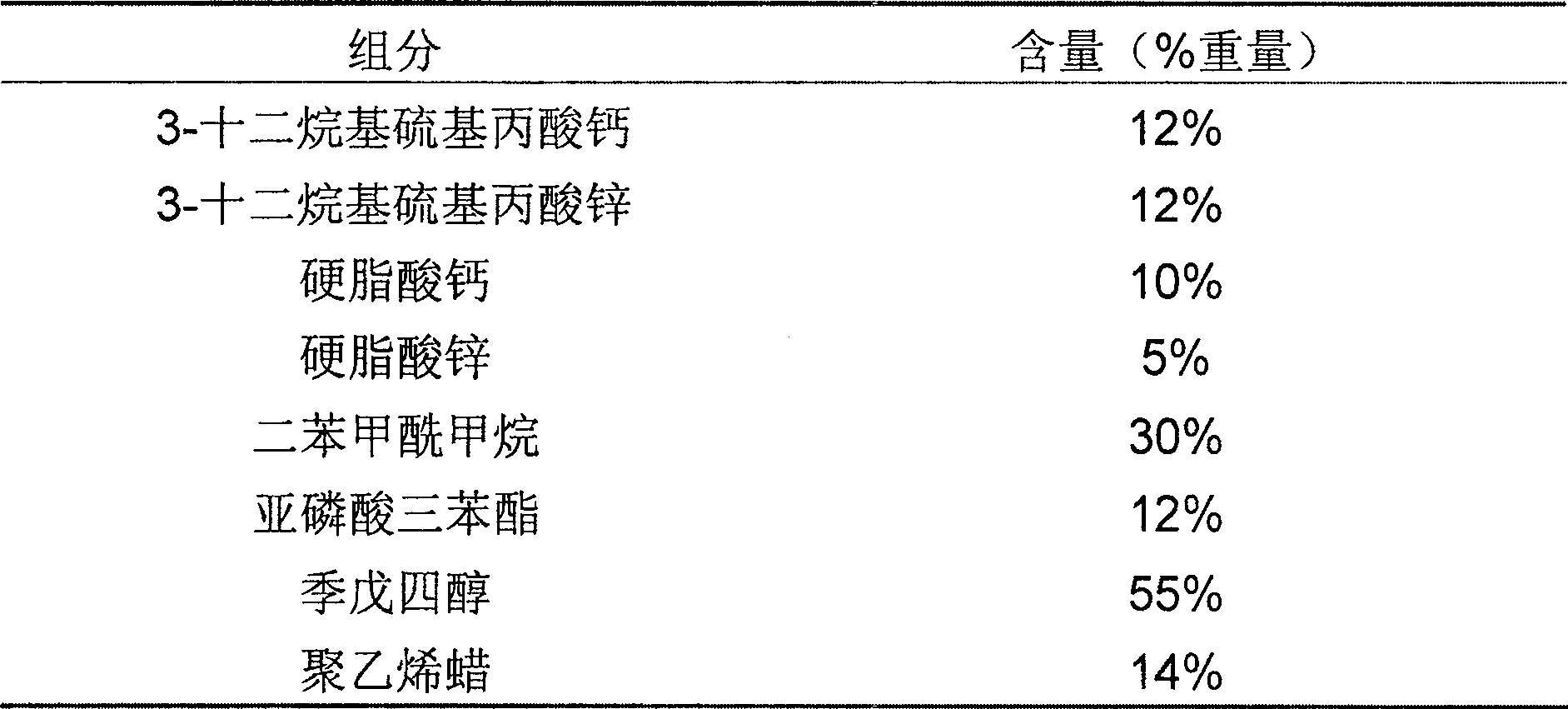

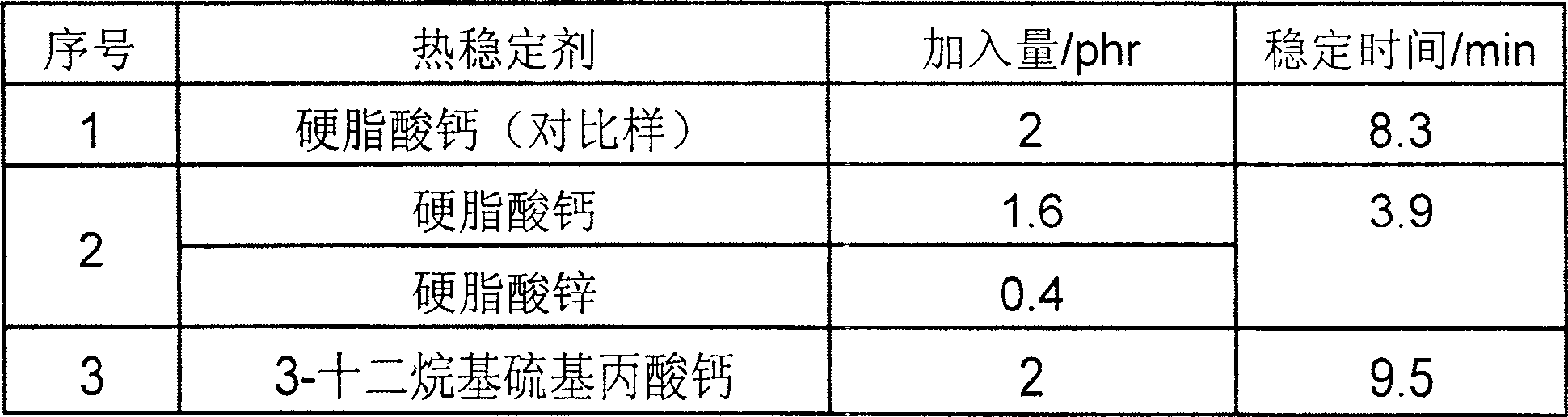

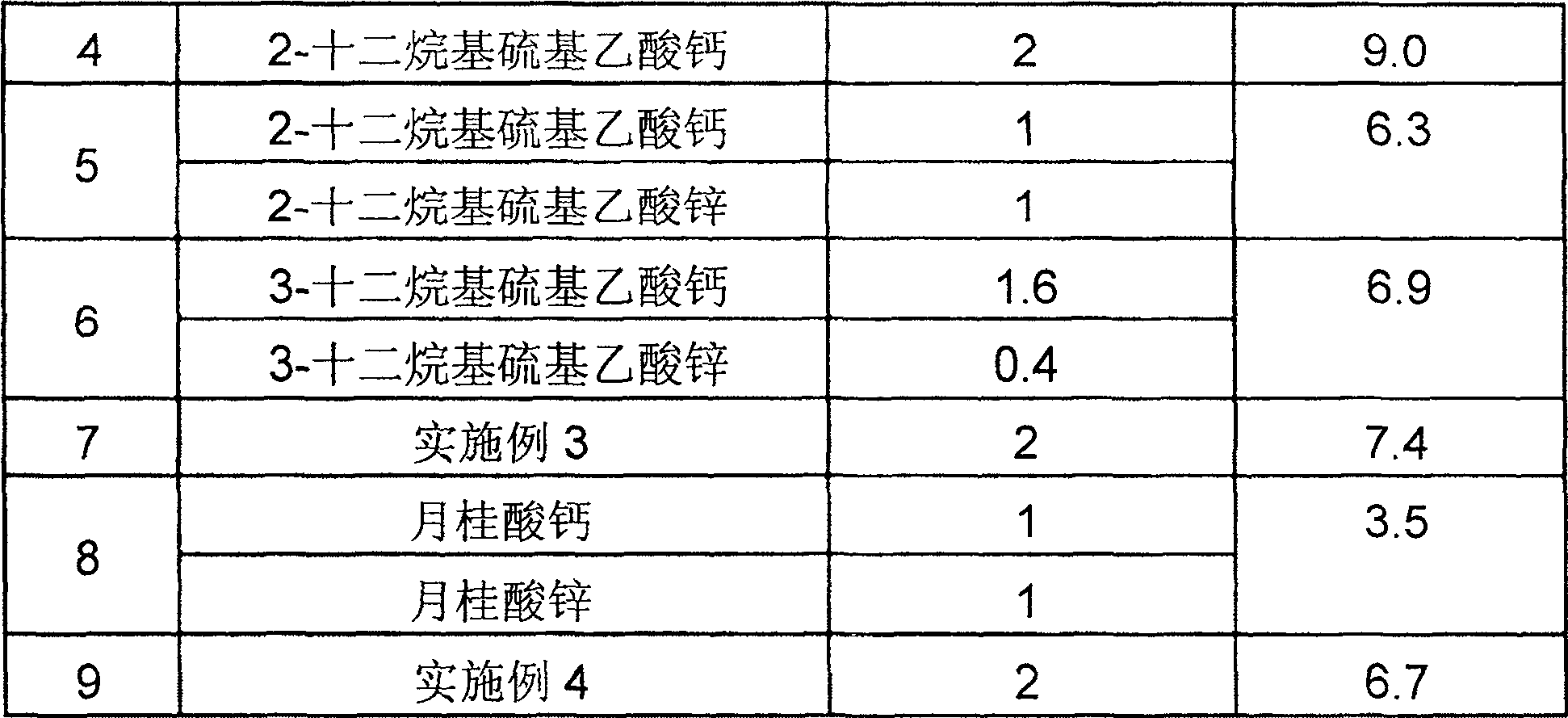

Composite stabilizer of metal salt of organic carboxylic acid containing sulfur in use for polymer containing halogen, and application

This invention discloses a sulfur-containing metal carboxylate composite stabilizer and its application. The sulfur-containing metal carboxylate composite stabilizer comprises: sulfur-containing metal carboxylate, metal salt stabilizer, organic metal stabilizer, lubricant, and organic auxiliary stabilizer. The sulfur-containing metal carboxylate composite stabilizer can be used in halogen-containing polymers to increase their processing stability. The sulfur-containing metal carboxylate composite stabilizer has such advantages as long thermal stabilization period, low early coloration, and low toxicity.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

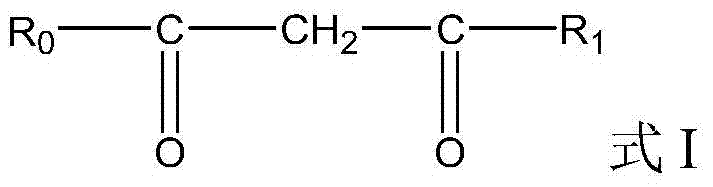

Environmental-friendly high-efficiency composite heat stabilizer for tribasic zinc PVC (polyvinyl chloride) and preparation method of environmental-friendly high-efficiency composite heat stabilizer

InactiveCN102153824AImprove thermal stabilityGood initial colorabilityPreparation of metal alcoholatesEnvironmental resistancePentaerythritol

The invention belongs to the field of a heat stabilizer for PVC (polyvinyl chloride) and relates to an environmental-friendly high-efficiency composite heat stabilizer for tribasic zinc PVC (polyvinyl chloride) and a preparation method of the environmental-friendly high-efficiency composite heat stabilizer. The environmental-friendly high-efficiency composite heat stabilizer for the tribasic zinc PVC (polyvinyl chloride) is prepared by performing a reaction of tribasic zinc, calcium stearate, a lubricant and an auxiliary heat stabilizer, wherein the tribasic zinc is prepared by mixing pentaerythritol and zinc oxide according to a weight ratio of 6-8:3 and performing a reaction for 4 to 6 hours at a temperature of 140 to 180 DEG C. The preparation method comprises the following steps of: adding the tribasic zinc and the calcium stearate into a reaction kettle for sufficiently mixing; adding the mixed materials into a kneading machine to knead for 15 to 25 minutes at a temperature of 100 to 120 DEG C; adding a lubricating agent and the auxiliary heat stabilizer in the kneading machine to knead and stir for 25-35min; and carrying out discharging, tabletting, sieving and packaging to obtain the finished product. The prepared environmental-friendly high-efficiency composite heat stabilizer for the tribasic zinc PVC (polyvinyl chloride) has the characteristics that the environmental-friendly high-efficiency composite heat stabilizer is difficult to separate out and has good stabilizing effect; the balancing torque can be reduced; and the processing property is improved. Moreover, the environmental-friendly high-efficiency composite heat stabilizer for the tribasic zinc PVC (polyvinyl chloride) has the advantages of high efficiency and environment protection.

Owner:慧科高新科技股份有限公司

Environment-friendly type modified master batch and preparation method thereof

InactiveCN101186730AHigh impact strengthImprove mechanical propertiesWaxLinear low-density polyethylene

The invention relates to an environment-friendly modified master batch and process for preparation, the product can not only reduce the cost of production, but also enhance mechanical property of filling plastics, and has the advantages of simple technique preparing of the preparation, good fluidity of the prepared master batch and easy forming. The environment-friendly modified master batch comprises the following components by weight: heavy calcium carbonate of 2000-3000 mesh sizes, linear low density polyethylene, polyethylene wax, corrdination type titanate coupling agent, thinner, compound wax, zinc stearate grease, calcium stearate and auxiliary agent. The process for preparation of the invention is that the heavy calcium carbonate of 2000-3000 mesh sizes is placed in a mixer under the rapid of 200-300 r / min to mix for 15 minutes, the corrdination type titanate coupling agent and the thinner are charged to churn up for 5-10 minutes, and then the rest raw materials are charged for mixing 1-3 minutes to obtain mixture, the mixture is placed in a co-rotating twin-screw granulator for granulating, hot cutting, cooling and packing to prepare the environment-friendly modified master batch.

Owner:NANTONG BAOJIALI NEW MATERIAL CO LTD

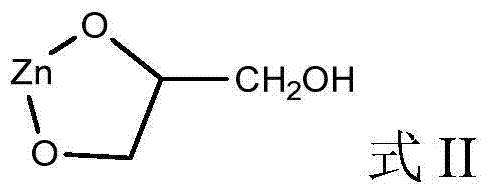

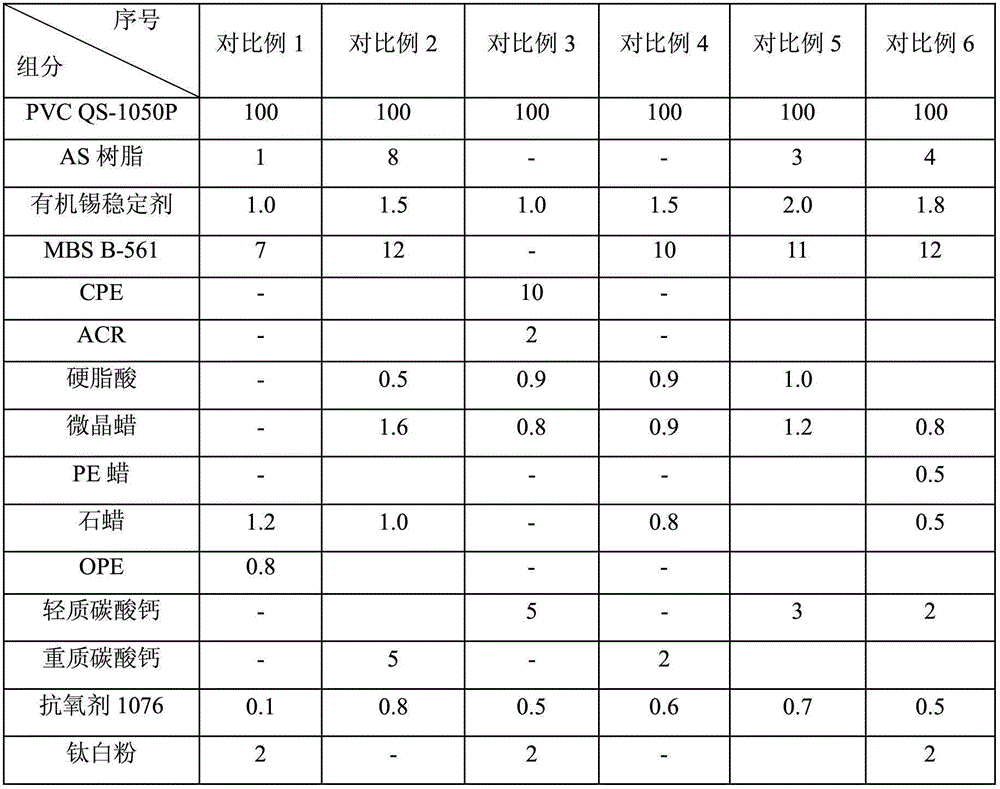

CPVC (Chlorinated Polyvinyl Chloride) composition with good heat stability and preparation method thereof

The invention relates to a CPVC (Chlorinated Polyvinyl Chloride) composition with good heat stability and a preparation method thereof, belongs to the field of high-molecular processing materials, and mainly relates to the CPVC composition with good heat stability and the preparation method thereof. The CPVC composition is prepared from the following components in parts by weight: 100 parts of CPVC resin, 3-6 parts of composite stabilizer, 0.5-1.5 parts of internal lubricating agent, 0.5-1.5 parts of external lubricating agent, 6-12 parts of impact modifier and 3-20 parts of filling agent. The CPVC composition with good heat stability, which is disclosed by the invention, can enhance the heat stability of the CPVC composition in a processing process, thereby solving the problem of difficult processing of the CPVC composition.

Owner:CHINA PETROLEUM & CHEM CORP

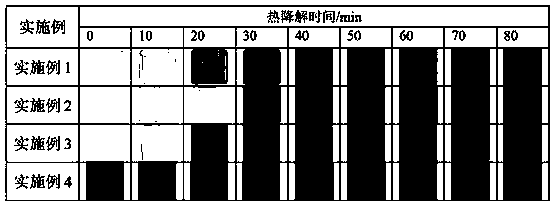

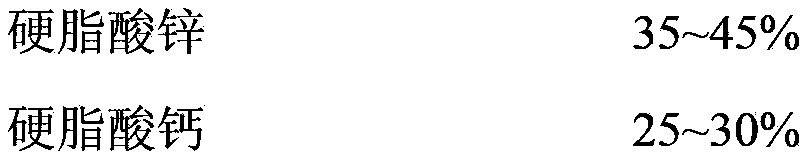

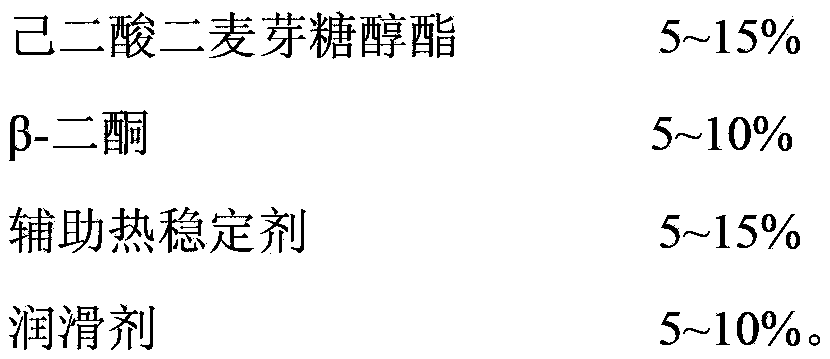

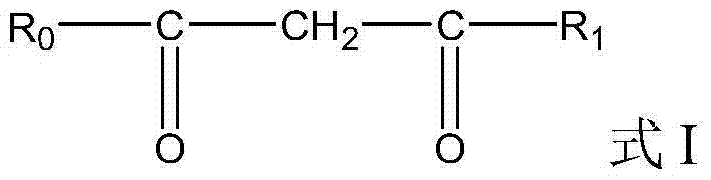

Calcium-zinc stearate and adipic acid di-maltitol ester PVC stabilizer and manufacturing method thereof

The invention relates to a calcium-zinc stearate and adipic acid di-maltitol ester PVC stabilizer and a manufacturing method thereof, which belong to the field of heat stabilizers for polyvinyl chloride (PVC) processing. Through adding adipic acid di-maltitol ester to carry out compounding with zinc stearate, calcium stearate, beta-diketone, a lubricant and an auxiliary heat stabilizer, a high-performance calcium-zinc stearate and adipic acid di-maltitol ester PVC composite heat stabilizer is obtained. A novel heat stabilizer prepared by using the method disclosed by the invention has the characteristics of ideal initial color, good long-term heat stabilization effect, and capability of promoting the plasticizing, lowering the balance torque, and improving the processing performance. The heat stabilizer prepared by using the method disclosed by the invention has the advantages of high efficiency and environment friendliness.

Owner:慧科高新科技股份有限公司

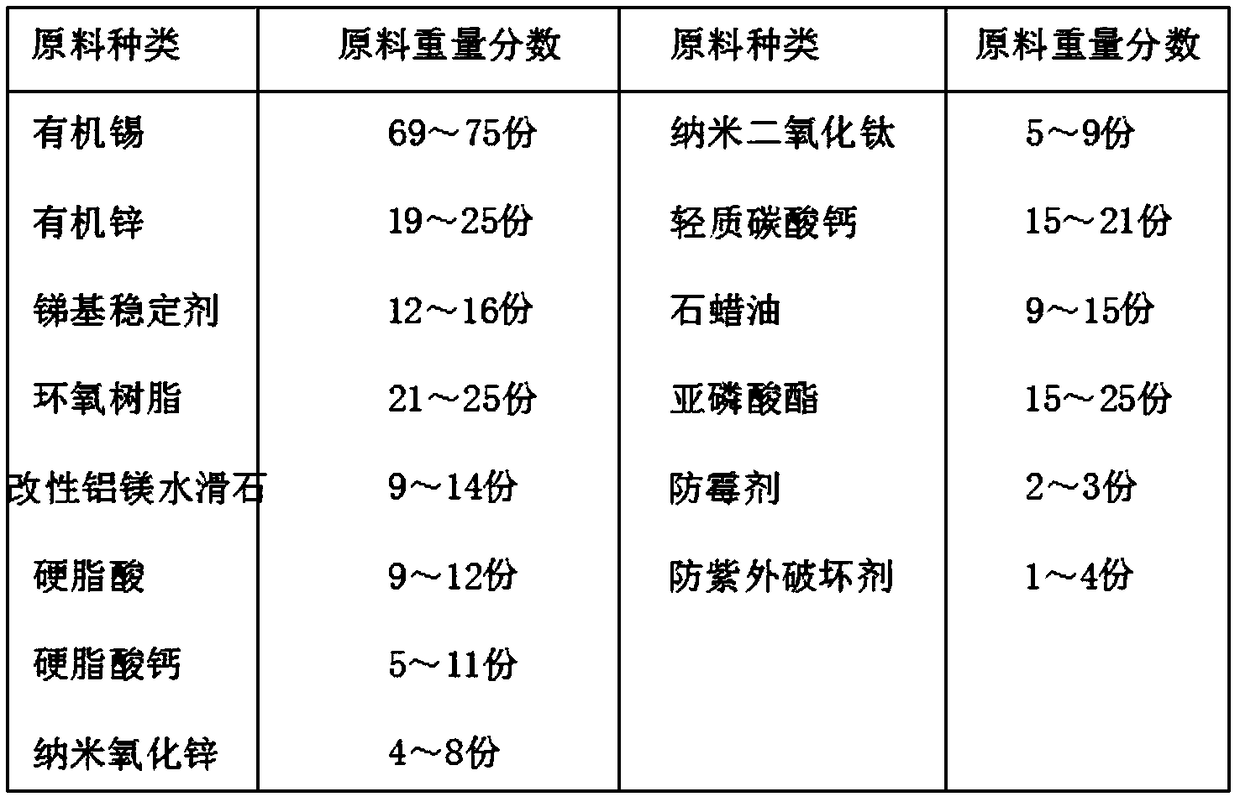

Environmental protection PVC section bar organic tin stabilizing agent

The invention relates to an environmental protection PVC section bar organic tin stabilizing agent. The environmental protection PVC section bar organic tin stabilizing agent comprises 69 to 75 partsof organic tin, 19 to 25 parts of organic zinc, 12 to 16 parts of an antimony based stabilizing agent, 21 to 25 parts of epoxy resin, 9 to 14 parts of modified magnesium aluminum hydrotalcite, 9 to 12parts of stearic acid, 5 to 11 parts of calcium stearate, 4 to 8 parts of nanometer zinc oxide, 5 to 9 parts of nanometer titanium dioxide, 15 to 21 parts of light calcium carbonate, 9 to 15 parts ofparaffin oil, and 15 to 25 parts of a phosphite ester. The environmental protection PVC section bar organic tin stabilizing agent is prepared from novel environment-friendly materials at a scientificand reasonable ratio, conventional environment protection safe raw materials are adopted, so that excellent heat stability and processing performance are achieved; the environmental protection PVC section bar organic tin stabilizing agent possesses excellent heat stability and processing performance, is nontoxic, is friendly to the environment, is low in cost; in PVC processing process, the plasticizing performance is excellent, balance torque is reduced; the light transparency is excellent; cost is low; heat stability is increased; and section bar welding strength is high.

Owner:广德粤华塑业制品有限公司

Organic acid and rare earth composite heat stabilizer for PVC (polyvinyl chloride)

The invention discloses an organic acid and rare earth composite heat stabilizer for PVC (polyvinyl chloride). The composite heat stabilizer is prepared by chemically synthesizing a heat stabilizer, lanthanum carbonate, nitric acid, zinc stearate, cerium carbonate, a solvent, sodium hydroxide, a composite antioxidant, hexadecanol, glycerin and mineral oil. According to the composite heat stabilizer, synthesized lanthanum stearate is compounded with other heat stabilizers, so that the thermal degradation temperature of PVC can be increased, the thermal stabilization time of PVC can be prolonged, the balance torque of the PVC can be reduced, the PVC processing power can be effectively reduced, and a large amount of effective energy resources are saved.

Owner:SUZHOU YUZHICHENG TRADE

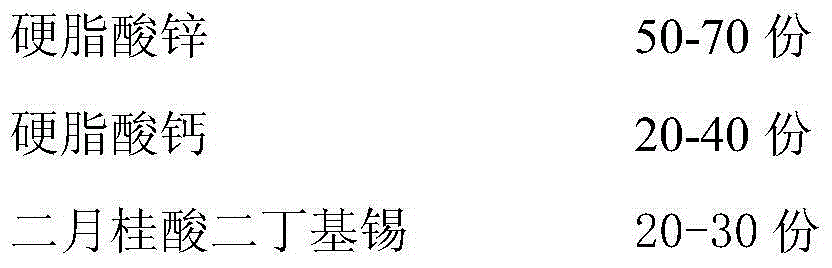

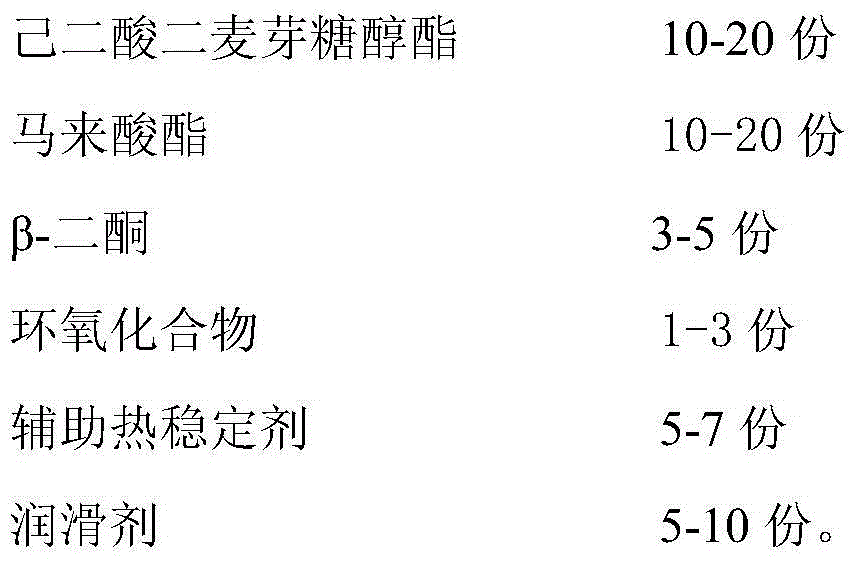

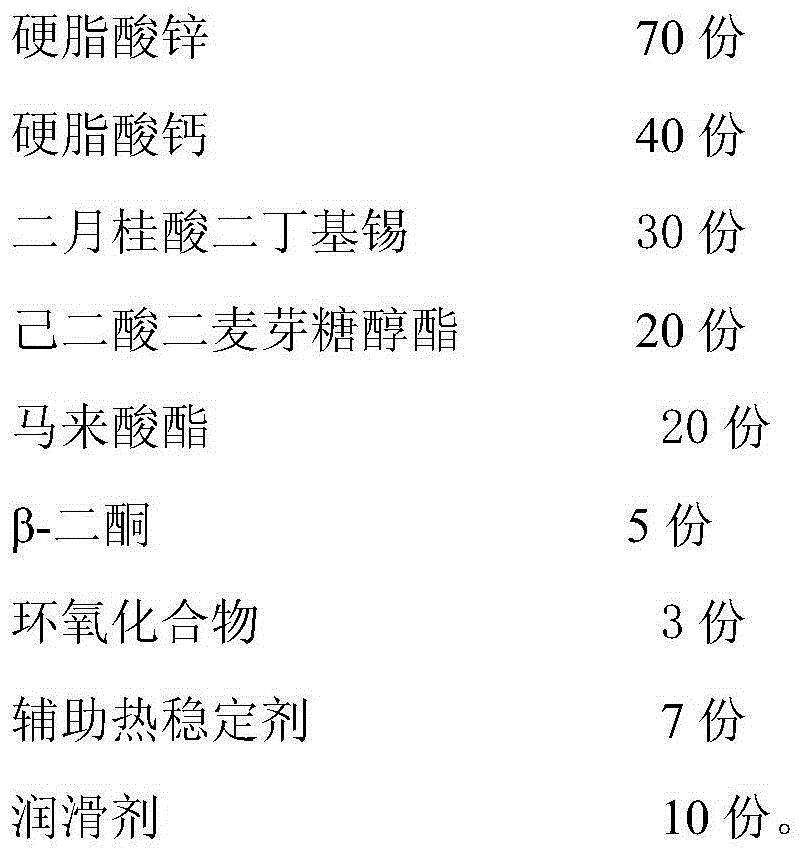

Composite PVC stabilizer

InactiveCN105778321AImprove long-term thermal stabilityReduce balance torquePolyvinyl chlorideKetone

The invention relates to a composite PVC stabilizer and a preparation method thereof. The invention relates to the field of polyvinyl chloride (PVC) processing heat stabilizers. The stabilizer is prepared from the following raw materials, by mass: 50-70 parts of zinc stearate, 20-40 parts of calcium stearate, 20-30 parts of dibutyltin dilaurate, 10-20 parts of dimaltitol adipate, 10-20 parts of maleate, 3-5 parts of beta-dione, 1-3 parts of an epoxy compound, 5-7 parts of an auxiliary heat stabilizer, and 5-10 parts of a lubricant. With the materials, the high-performance calcium-zinc stearate and dimaltitol adipate PVC composite heat stabilizer is prepared. When the novel heat stabilizer provided by the invention is used in PVC plastic processing, characteristics such as ideal initial color and good long-time heat stabilization effect. Also, plasticization can be promoted, balance torque can be reduced, and processing performance can be improved. The heat stabilizer provided by the invention is highly efficient and environment-friendly.

Owner:淄博龙沙高分子材料科技有限公司

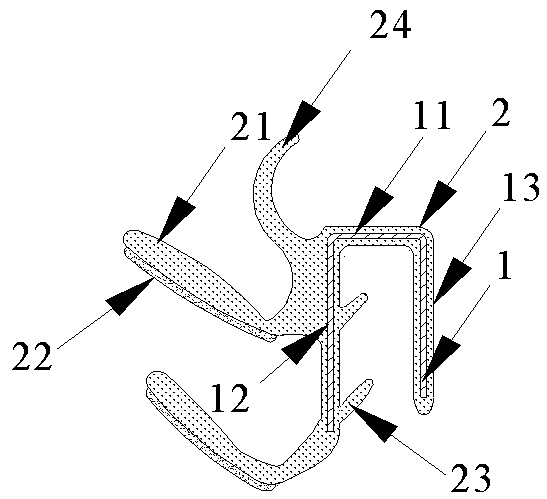

Outside sealing strip of automobile window and manufacturing method thereof

ActiveCN103373204AEasy to processConducive to lightweightEngine sealsVehicle sealing arrangementsChlorinated polyvinyl chlorideAlloy

The invention provides an outside sealing strip of an automobile window. The outside sealing strip comprises a framework and a base body, wherein the framework is made of alloy plastics of chlorinated polyvinyl chloride and acrylonitrile-butadiene-styrene, the framework is in a long-strip shape, and a fracture surface of the framework is shaped like a reversed U-shaped structure. The reversed U-shaped structure comprises a top portion, a first lateral portion close to window glass and a second lateral portion away from the window glass. The base body is made of polyvinyl chloride and wraps on the periphery of the framework, a first protrusion is arranged on the base body on the outer side of the first lateral portion, and lint is arranged on the side of the first protrusion contacted with the window glass. Burrs are arranged on the contact portion of the base body on the inner side of the first lateral portion and an automobile door panel. The invention further provides a manufacturing method of the outside sealing strip of the automobile window. The outside sealing strip of the automobile window is good in binding force, and the manufacturing method of the outside sealing strip is simple, omits steps of adjusting formed steel belts in the prior art and reduces procedures.

Owner:BYD CO LTD

Hydrotalcite-dimer acid lanthanum composite environmental protection stabilizer for PVC, and preparation method thereof

The present invention provides a hydrotalcite-dimer acid lanthanum composite environmental protection stabilizer for PVC, wherein the hydrotalcite-dimer acid lanthanum composite environmental protection stabilizer is prepared from the following raw materials by weight: 20-30 parts of modified magnesium aluminum hydrotalcite, 10-12 parts of dibutyl tin oxide, 6-9 parts of dimer acid lanthanum, 1-3 parts of triphenyl phosphite, 3-6 parts of zinc stearate, 2-4 parts of epoxidized soybean oil, 5-6 parts of beta-diketone, 2-4 parts of 2,2'-thiobis(4-tert-octylphenoloxy)nickel, 12-15 parts of triethyl acetyl citrate, 1-2 parts of montan wax, and 10-15 parts of attapulgite. According to the present invention, the PVC stabilizer has characteristics of good thermal stability, good processing performance, environmental protection, no toxicity, low cost, good plasticity and balance torque reducing during the PVC processing process, and low cost.

Owner:HWASU

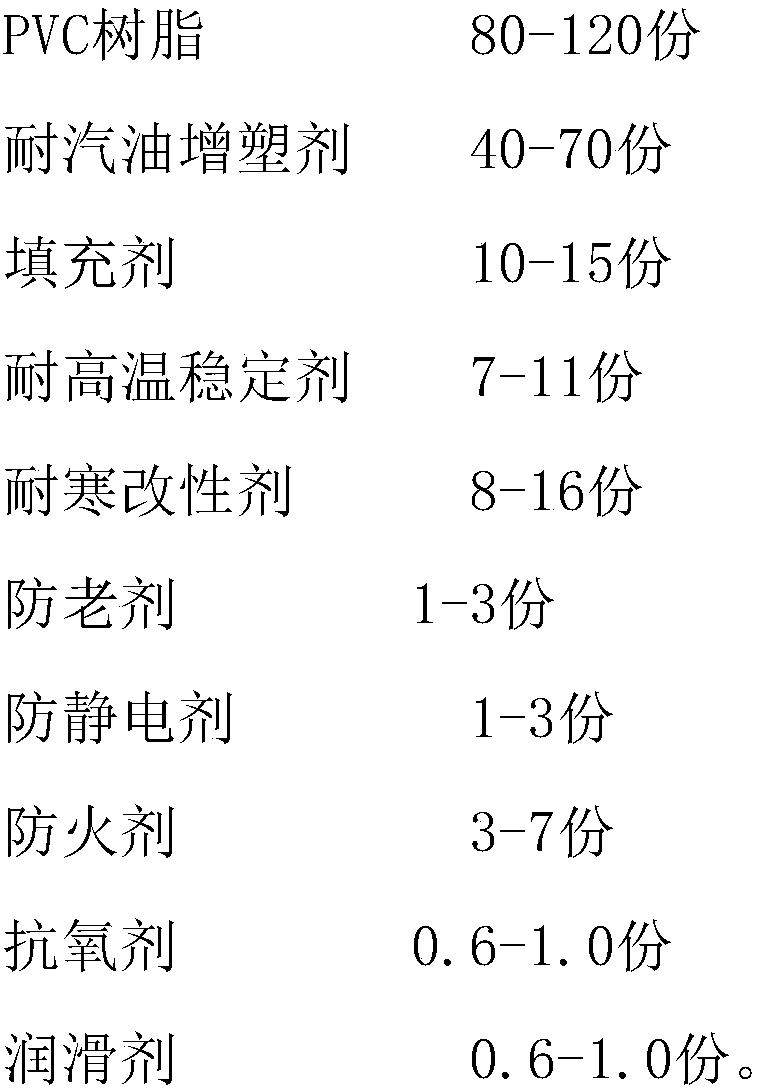

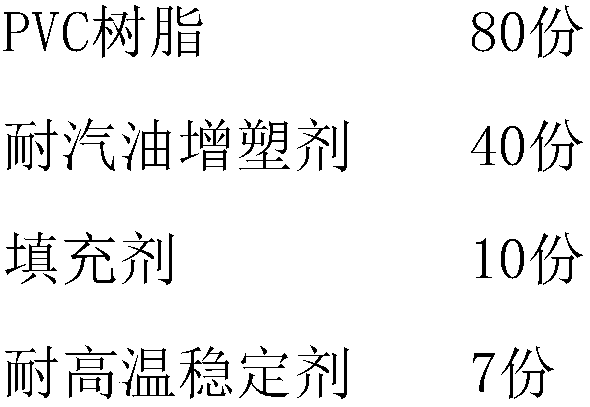

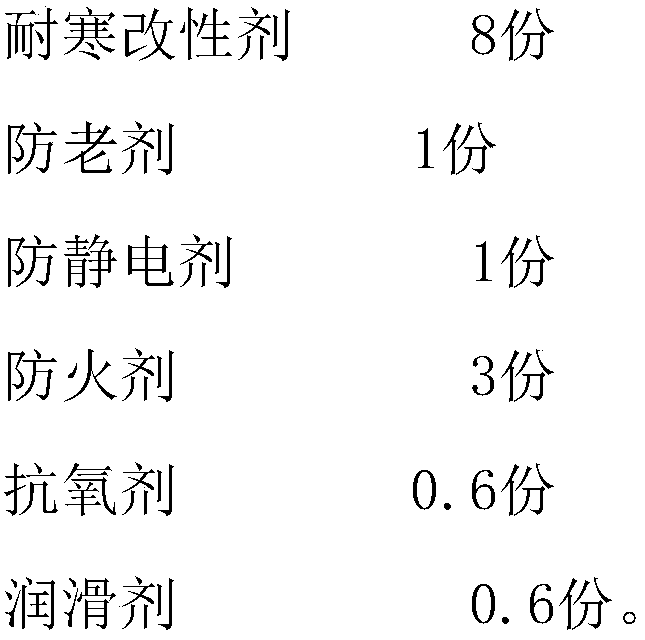

PVC modified material used for automobile charging pile and preparation method thereof

The invention relates to the technical field of PVC materials, and specially relates to a PVC modified material used for an automobile charging pile and a preparation method thereof. The PVC modifiedmaterial includes, by weight, the following raw materials: 80-120 parts of PVC resin, 40-70 parts of a gasoline resistance plasticizer, 10-15 parts of a filler, 7-11 parts of a high temperature resistance stabilizer, 8-16 parts of a cold resistance modifier, 1-3 parts of an anti-aging agent, 1-3 parts of an antistatic agent, 3-7 parts of a fire retardant, 0.6-1.0 part of an antioxidant, and 0.6-1.0 part of a lubricant. The PVC modified material has the characteristics of good antistatic effect, environmental protection, excellent performance of high temperature resistance and low temperature resistance, good effects of gasoline resistance, antioxidation and fire prevention, and good processing properties; and the PVC modified material is suitable for the automobile charging pile.

Owner:广东祺龙科技有限公司

Preparation method of ultra-tough and cold-resistant nano-particle modified nylon composite material

The invention relates to a preparation method of ultra-tough and cold-resistant nano-particle modified nylon composite material. The preparation method comprises the following steps: enabling unsaturated double bond monomers including one or more of cis-butenedioic anhydride, acrylonitrile, methacrylic acid and vinyl acetate, an initiator including one or more of dibenzoyl peroxide, azobisisoheptonitrile and tert-butyl peroxybenzoate to be subjected to polymerization reaction with polypropylene; performing reflux extraction and refinement with acetone to obtain a polymer composite compatilizer, performing surface modification on slurry of nano-particles and water, feeding the surface modified slurry and nylon masterbatch into an internal mixer, adding a product to a twin-screw extruder, performing plasticizing and extruding braces, cooling the braces to room temperature, and granulating and drying the braces to obtain the composite material; introducing nano-particles on the basis of nylon taken as a matrix, performing coupling treatment by the surface polymer composite compatilizer and then performing modification. Interfacial adhesion of the nano-particles in the nylon matrix isimproved, the dispersion property is improved, the crystallization rate is increased, and accordingly, mechanical property, toughness, cold resistance and weather resistance of ropes made of the composite material are improved.

Owner:盐城神威制绳有限公司

High-toughness flame-retardant cable for electric power circuit and preparation process of cable

InactiveCN107936439AGood mechanical propertiesGood weather resistancePlastic/resin/waxes insulatorsMaleic anhydrideWeather resistance

The invention provides a high-toughness flame-retardant cable for an electric power circuit and a preparation process of the cable. The high-toughness flame-retardant cable is prepared from raw materials of a hydrogenated polystyrene-butadiene block copolymer, polypropylene, maleic anhydride, an MCA (melamine cyanurate) flame retardant, aluminum diethyl phosphinate, montmorillonite, silicone powder, dicumyl peroxide, an antioxidant and the like. The hydrogenated polystyrene-butadiene block copolymer has good mechanical property, weather resistance, heat resistance and compressive deformation resistance, and the dielectric strength reaches 39MV / m; the polypropylene has the characteristics of high strength, large hardness, wear resistance and the like, and has relatively high dielectric coefficient and breakdown voltage; the elastic strength of the composite material obtained by modifying a composite material through the montmorillonite, the silicone powder and the maleic anhydride is increased, the thermal stability is improved, the tensile strength of the composite material is increased to 12.75Mpa, the elongation at break reaches 932.5%, the water resistance is slightly reduced, and the balance torque during melting is reduced; with the addition of the antioxidant, the flame retardancy and thermal stability of the composite material are improved obviously, and the flame resistance of the composite material is increased to 32.

Owner:YANCHENG POWER SUPPLY CO STATE GRID JIANGSU ELECTRIC POWER CO +2

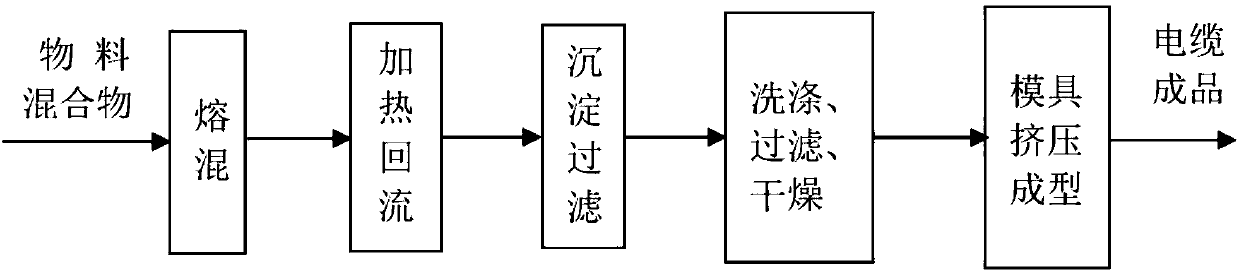

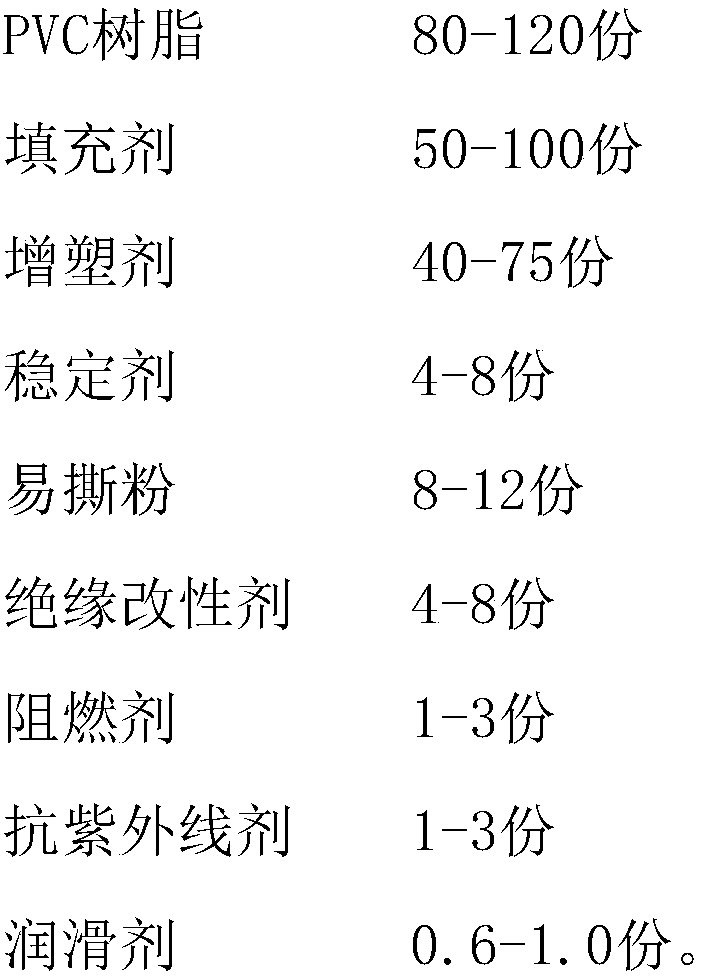

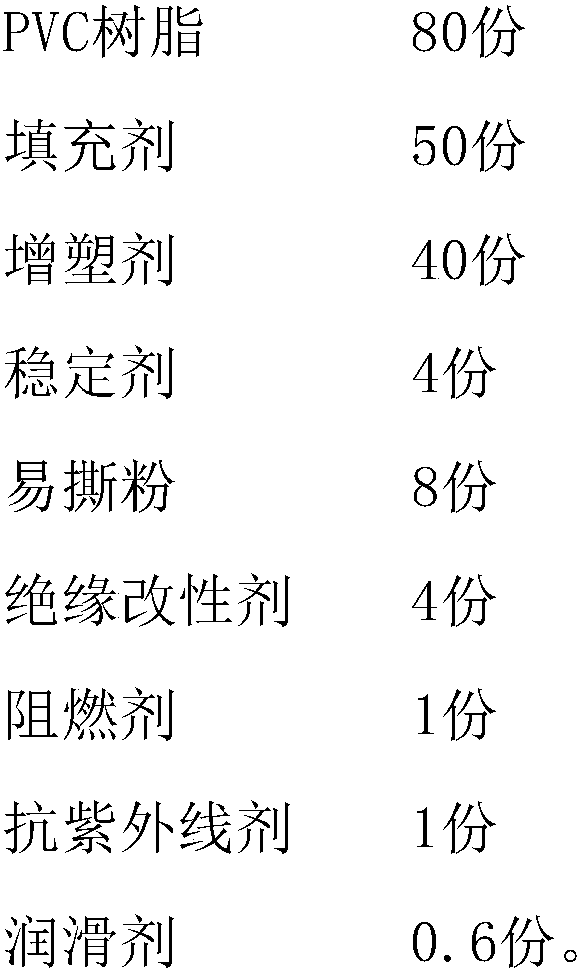

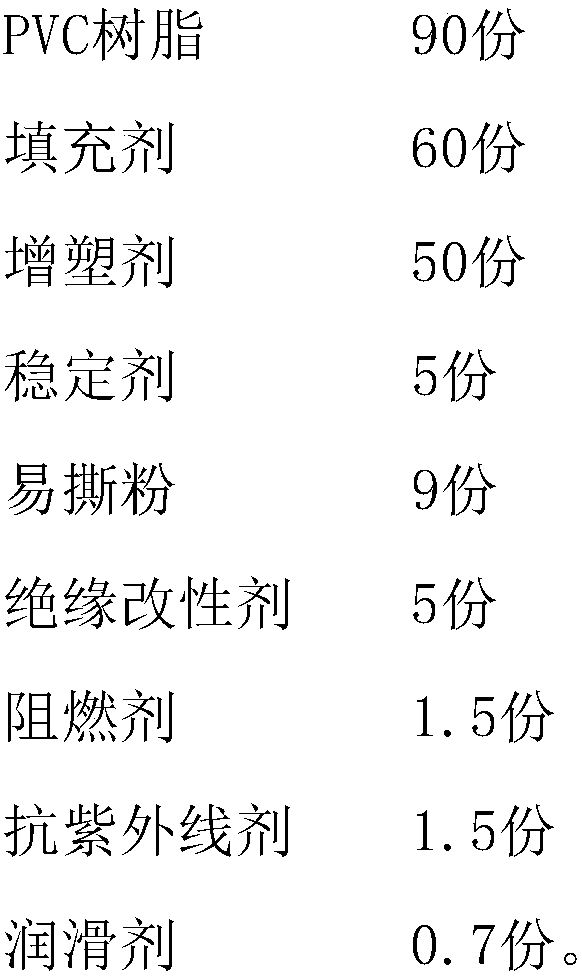

PVC (polyvinyl chloride) modified material for industrial peelable wire and preparation method of modified material

InactiveCN108659387AGood initial colorabilityImprove long-term thermal stabilityPlastic/resin/waxes insulatorsPlasticizerPolyvinyl chloride

The invention relates to the technical field of PVC (polyvinyl chloride) materials, in particular to a PVC modified material for an industrial peelable wire, and a preparation method of the PVC modified material. The modified material comprises the following raw materials in parts by weight: 80-120 parts of PVC resin, 50-100 parts of a filler, 40-75 parts of a plasticizer, 4-8 parts of a stabilizing agent, 8-12 parts of a peelable powder, 4-8 parts of an insulation modifier, 1-3 parts of a fire retardant, 1-3 parts of anti-ultraviolet agent and 0.6-1.0 part of a lubricant. The PVC modified material is good in peelable effect, environment-friendly, good in flame retardance effect, good in ultraviolet protection effect, excellent in insulation and processability, and applicable to the industrial peelable wire.

Owner:广东祺龙科技有限公司

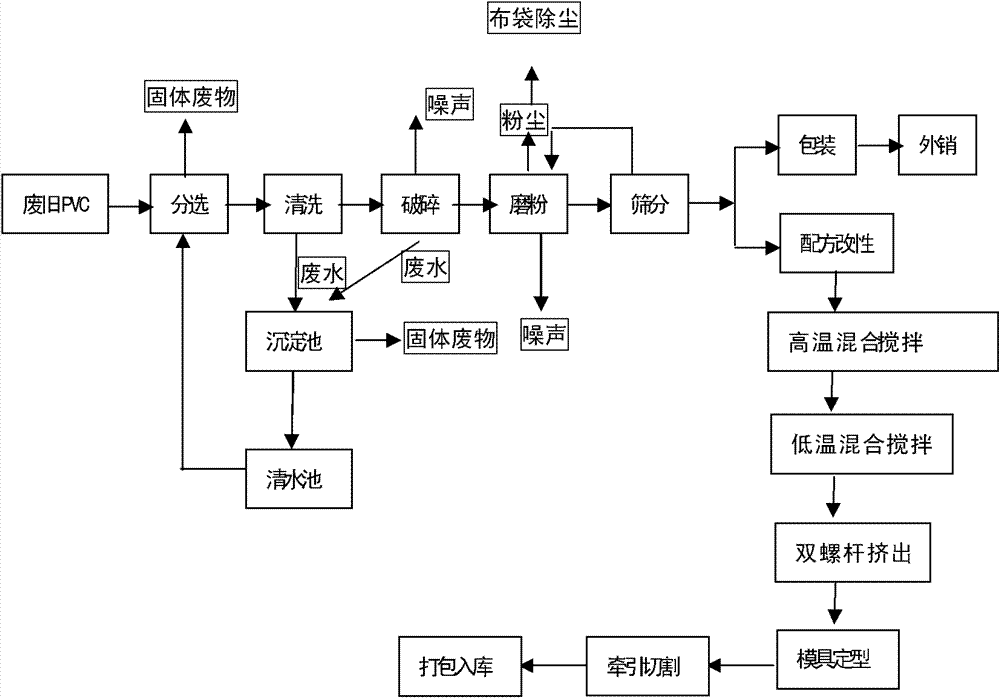

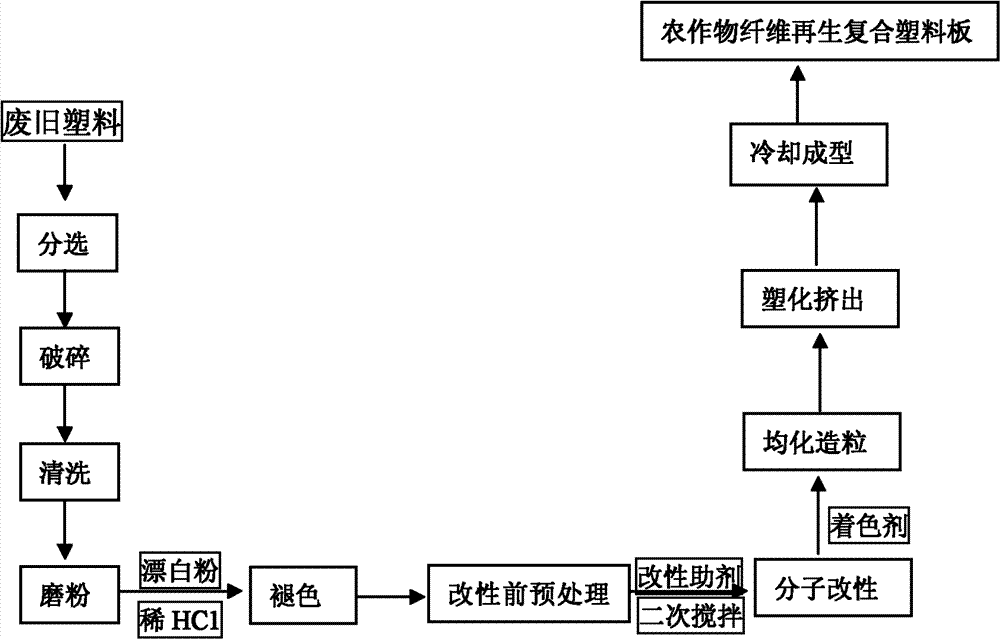

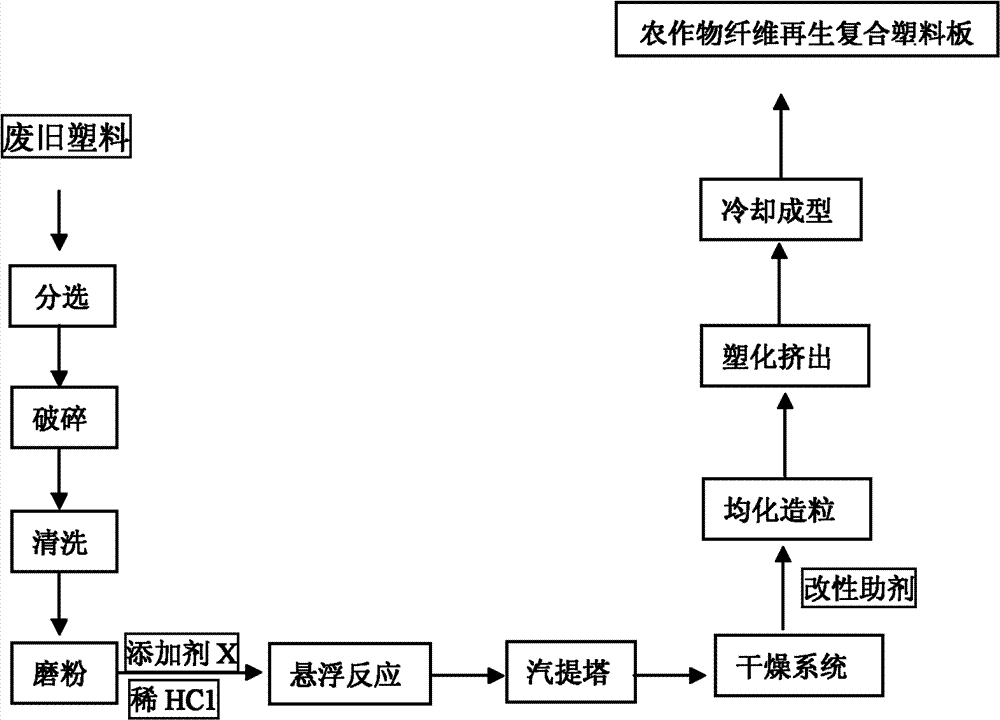

Crops waste material regenerated composite plastic plate and its production process

The invention provides a crops waste material regenerated composite plastic plate and its production process, the process comprises the following steps: using a waste and old PVC material and a crop waste material as raw materials, classifying, fragmenting, cleaning, drying, milling, pretreating, molecule modifying to prepare crops waste material regenerated composite plastic plate. No pollutant is generated during the whole production process, the energy consumption is low, the regenerated composite plastic plate has the advantages of low price and stable quality.

Owner:HUNAN ZHONGYUE PLASTIC

High-strength PVC tubular product composition

The invention belongs to the technical field of high polymer materials, and specifically relates to a high-strength PVC tubular product composition. Through the technical scheme, the high-strength PVC tubular product composition is prepared from the following components (in parts by weight): 100 parts of PVC, 2 to 4 parts of a processing modifier, 1.0 to 2.5 parts of a heat stabilizer, 8 to 11 parts of a flexibilizer, 1.5 to 3.5 parts of a lubricating agent, 0 to 5 parts of a filler, 0.05 to 0.1 part of an antioxygen 1076 and 0 to 2 parts of a coloring agent. A rigid polyvinyl chloride tubular product produced by using the composition disclosed by the invention has high tenacity and relatively high strength, and is high in impact performance and relatively high in physical and mechanical properties.

Owner:FOSHAN RUIJIAN SPORTS EQUIP CO LTD

Preparation method of HDPE polymer film with high strength and high impact resistance

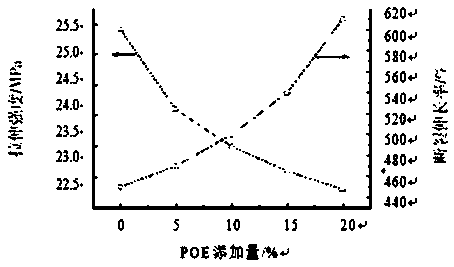

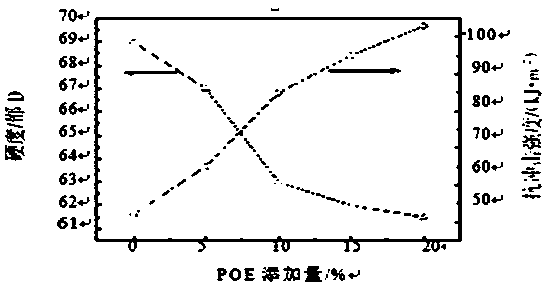

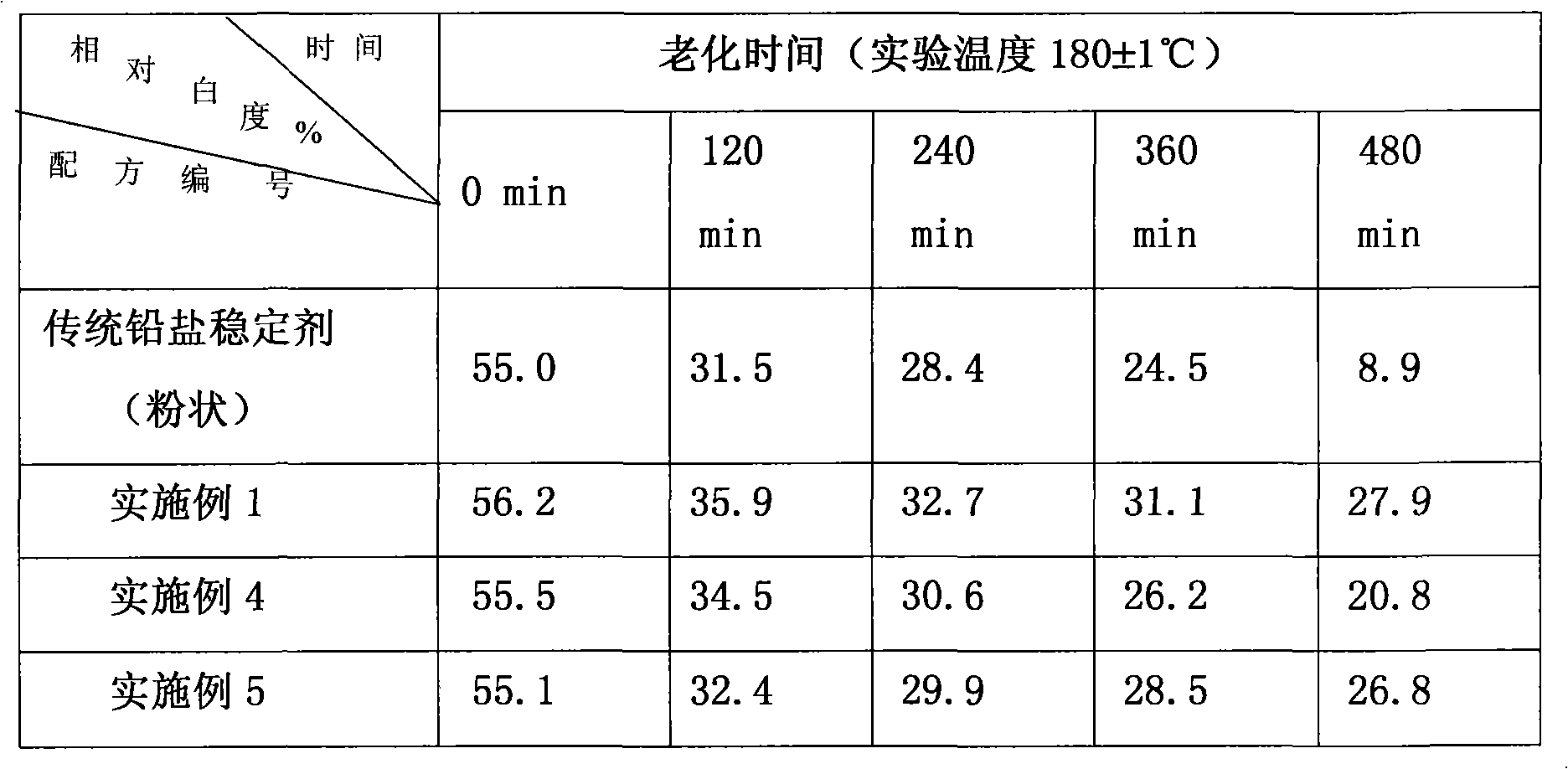

The invention discloses a preparation method of an HDPE polymer film with high strength and high impact resistance. The preparation method comprises the steps of material preparation, blending pelleting, CaCO3 adding, drying, preheating, pressure maintaining and cooling. Toughening modification is carried out on HDPE by using a polyolefin elastomer (POE), and simultaneously, a melt blending methodis adopted, an HDPE waterproof roll is prepared by filling an HDPE / POE blending system with an inorganic filler CaCO3, and the prepared HDPE film has the advantages of excellent physical index and high impact resistance; the tenacity of HDPE can be improved greatly through the addition of POE, the tensile strength is reduced, the elongation at break is increased, the hardness is reduced, and theimpact resistance is increased; the balance torque of HDPE can be reduced through the addition of CaCO3 and POE, the processing fluidity becomes higher, and the impact resistance is high; and moreover, the preparation method disclosed by the invention is simpler and low in equipment requirements, and has a preferable popularization effect.

Owner:潍坊市宇虹防水材料(集团)有限公司

Method for preparing hydrophobic nanometer hydrotalcite

InactiveCN101538019BUniform particle size distributionImprove hydrophobicityNanostructure manufactureOxide/hydroxide preparationPolymer scienceHydrotalcite

The invention relates to a method for preparing hydrophobic nanometer hydrotalcite. The hydrophobic nanometer hydrotalcite with Mg<2+> / Al<3+> of which the molar ratio is 2-3:1 is prepared by adopting a coprecipitation method by adding eunatrol, and leached by using methylbenzene under the action of a phase transfer agent. The hydrophobic nanometer hydrotalcite can be mixed with calcium stearate and zinc stearate and then is added with a lubricating agent, a surfaction agent and an auxiliary stabilizing agent to prepare a composite heat stabilizing agent for hydrophobic nanometer hydrotalcite base PVC. The hydrophobic nanometer hydrotalcite prepared by the method has better hydrophobicity and good compatibility with PVC matrixes, can be used as a stabilizing agent for processing plastics such as PVC, and the like and has the characteristics of no easy separation and good stabilizing effect. The addition of the hydrophobic nanometer hydrotalcite can reduce the balancing torque, improve the processing performance and reduce the cost.

Owner:慧科高新科技股份有限公司

Composite stabilizer of metal salt of organic carboxylic acid containing sulfur in use for polymer containing halogen, and application thereof

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

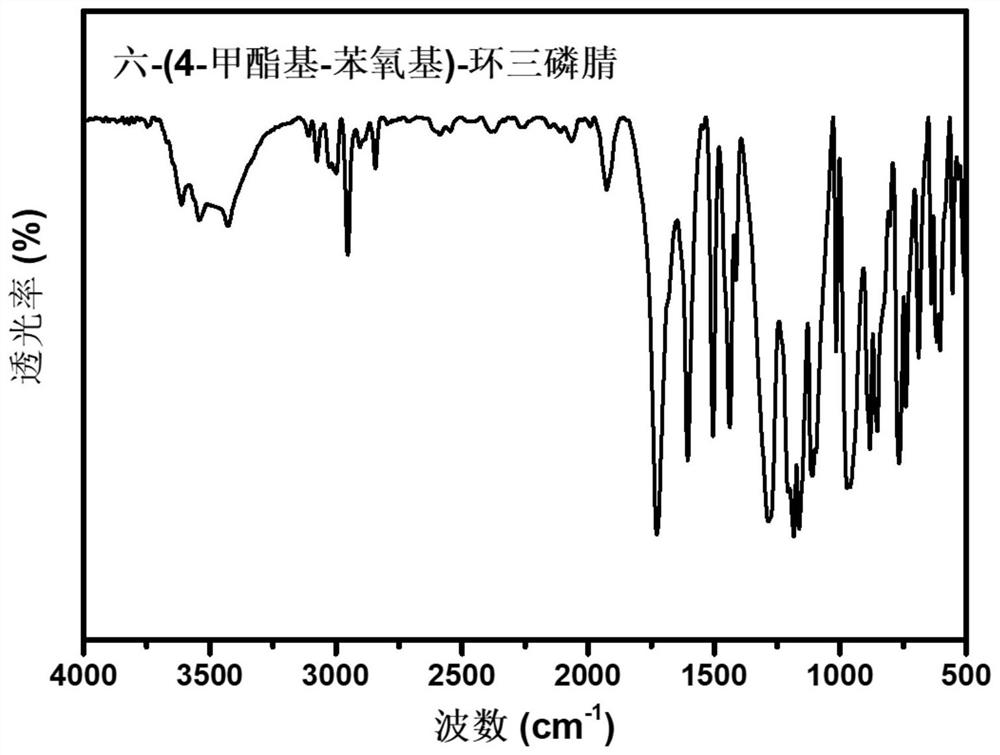

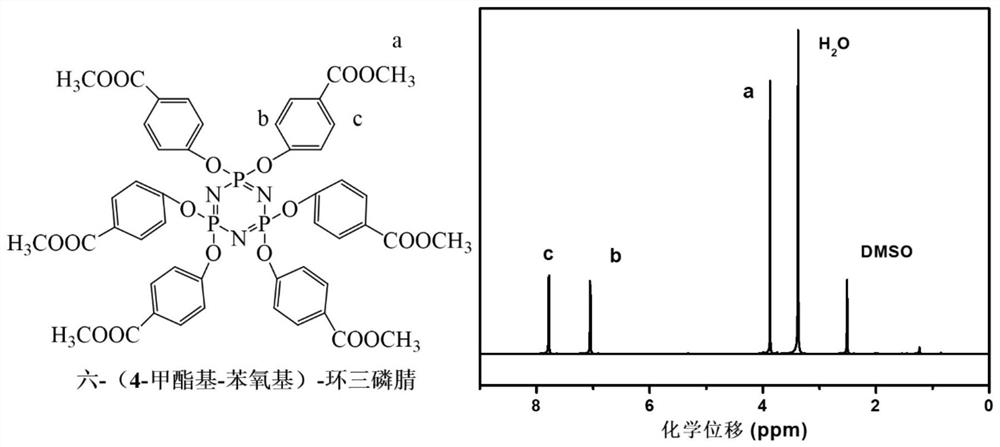

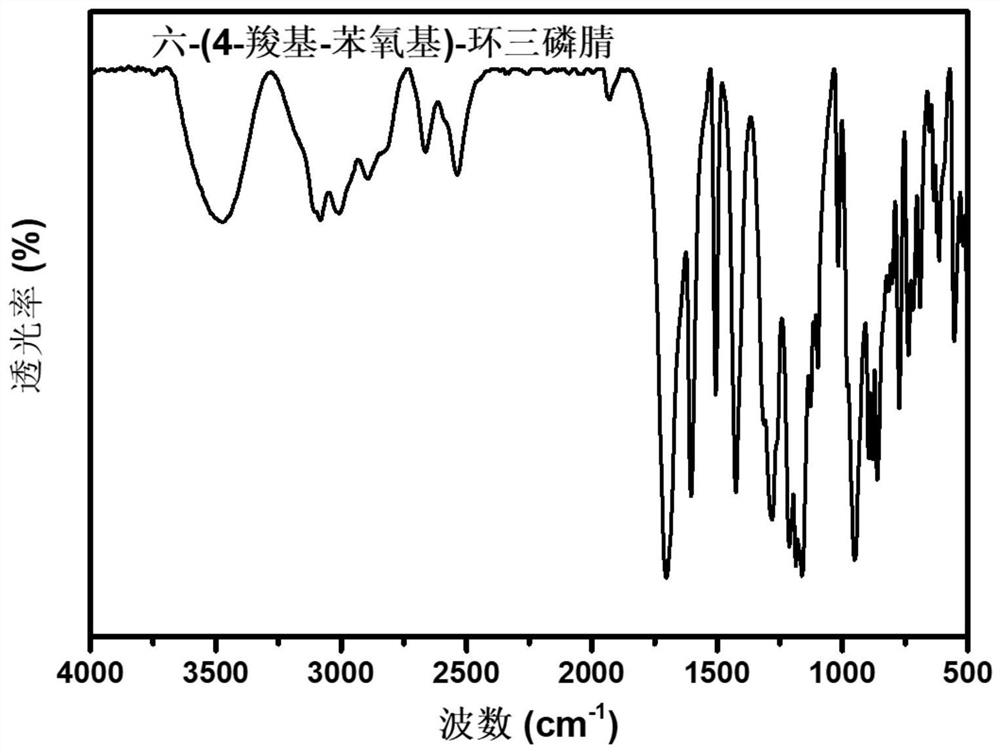

Star-structure fluorine-containing phosphazene flow modifier and preparation method and application thereof

ActiveCN112358507AReduce reunionReduce balance torqueGroup 5/15 element organic compoundsPotassium carbonatePyridyne

The invention discloses a star-structure fluorine-containing phosphazene flow modifier and a preparation method and application thereof. The preparation method comprises the following steps: dissolving hexachlorocyclotriphosphazene and methylparaben, heating, adding potassium carbonate, continuously reacting, cooling, carrying out suction filtration, and drying to obtain a solid product hexachlorocyclotriphosphazene-(4-methyl-phenoxy)-cyclotriphosphazene; mixing the obtained product with methanol, and then adding deionized water to react to obtain hexa-(4-carboxyl-phenoxy)-cyclotriphosphazene;dissolving the obtained product, heating to 80-90 DEG C, reacting, adding a solvent, fluoroalcohol, 4-dimethylaminopyridine and triethylamine, and reacting; and carrying out suction filtration and drying to obtain the star-structure fluorine-containing phosphazene flow modifier. Compared with an existing auxiliary agent, after the star-structure fluorine-containing phosphazene flow modifier is added, the balance torque of a system is reduced by 11.3%, the notch impact strength of the composite material is improved by 21.4%, and the limit oxygen index of the composite material is improved to 65.8% from 59.4%.

Owner:SOUTH CHINA UNIV OF TECH

Organic complex zinc composite heat stabilizer for PVC and preparation method thereof

The invention provides organic zinc complex compound heat stabilizer used for PVC and a preparation method of the organic zinc complex compound heat stabilizer. The compound heat stabilizer is prepared from main stabilizer and auxiliary heat stabilizer, wherein the mass ratio of the main stabilizer to the auxiliary heat stabilizer is 0.9-3.0 to 0.1-1.0, organic zinc complex and calcium stearate serve as the main stabilizer, and the auxiliary heat stabilizer is selected from at least one of stearic acid, polyhydric alcohols, hydrotalcite and zeolite. The organic zinc complex compound heat stabilizer has the advantages that when the compound heat stabilizer is used as stabilizer for processing PVC and other plastic, the compound heat stabilizer is not easy to separate out and the stabilization effect is good.

Owner:河北雄发新材料科技发展有限公司

Low energy consumption and high extrusion output pvc-m pipe composition

The invention belongs to the field of a polymer processing material, and mainly relates to a PVC-M (polyvinyl chloride) pipe composition with low energy consumption and high output capacity. The PVC-M pipe composition is prepared from the following components in parts by weight: 100 parts of PVC resin, 3-7 parts of processed modified resin, 4.5-8.0 parts of heat stabilizer, 6-12 parts of flexibilizer, 0.5-1.0 part of hindered phenol antioxidant, 1.0-2.0 parts of lubricating agent, 1-5 parts of filler, and 0-2 parts of coloring agent. A large-caliber pipe and a small-caliber pipe produced by the PVC-M pipe composition with low energy consumption and high output capacity disclosed by the invention have low extruder current and high pulling speed; and the problems of difficult extrusion, low yield and high energy consumption in the production process of the PVC-M pipe are solved.

Owner:CHINA PETROLEUM & CHEM CORP

Composite heat stabilizer for hydrophobic nano hydrotalcite-based PVC and preparation method thereof

Hydrophobic nano-hydrotalcite-based composite heat stabilizer for PVC is composed of the following raw materials in mass percentage: 30-50% calcium stearate, 10-20% zinc stearate, 10-30% hydrophobic nano-hydrotalcite, Lubricant 5-15%, surface modifier 4-7%, auxiliary heat stabilizer 5-15%. Wherein the hydrophobic nanometer hydrotalcite adopts the co-precipitation method, and sodium oleate is added to prepare the hydrophobic nanometer hydrotalcite with a molar ratio of Mg:Al of 2-3:1. The nanometer hydrotalcite prepared by the present invention has good hydrophobicity, and it can be used as a composite heat stabilizer for PVC, which can have good compatibility with PVC matrix, and can be used as a stabilizer for plastic processing such as PVC, and has the property that it is not easy to separate out , Good stability effect. Adding hydrophobic nano-hydrotalcite can reduce balance torque, improve processing performance and reduce cost. The preparation method of the invention has no pollution and low energy consumption.

Owner:慧科高新科技股份有限公司

Environmental-friendly high-efficiency composite heat stabilizer for tribasic zinc PVC (polyvinyl chloride) and preparation method of environmental-friendly high-efficiency composite heat stabilizer

InactiveCN102153824BImprove thermal stabilityGood initial colorabilityPreparation of metal alcoholatesPentaerythritolPolyvinyl chloride

The invention belongs to the field of a heat stabilizer for PVC (polyvinyl chloride) and relates to an environmental-friendly high-efficiency composite heat stabilizer for tribasic zinc PVC (polyvinyl chloride) and a preparation method of the environmental-friendly high-efficiency composite heat stabilizer. The environmental-friendly high-efficiency composite heat stabilizer for the tribasic zincPVC (polyvinyl chloride) is prepared by performing a reaction of tribasic zinc, calcium stearate, a lubricant and an auxiliary heat stabilizer, wherein the tribasic zinc is prepared by mixing pentaerythritol and zinc oxide according to a weight ratio of 6-8:3 and performing a reaction for 4 to 6 hours at a temperature of 140 to 180 DEG C. The preparation method comprises the following steps of: adding the tribasic zinc and the calcium stearate into a reaction kettle for sufficiently mixing; adding the mixed materials into a kneading machine to knead for 15 to 25 minutes at a temperature of 100 to 120 DEG C; adding a lubricating agent and the auxiliary heat stabilizer in the kneading machine to knead and stir for 25-35min; and carrying out discharging, tabletting, sieving and packaging to obtain the finished product. The prepared environmental-friendly high-efficiency composite heat stabilizer for the tribasic zinc PVC (polyvinyl chloride) has the characteristics that the environmental-friendly high-efficiency composite heat stabilizer is difficult to separate out and has good stabilizing effect; the balancing torque can be reduced; and the processing property is improved. Moreover, the environmental-friendly high-efficiency composite heat stabilizer for the tribasic zinc PVC (polyvinyl chloride) has the advantages of high efficiency and environment protection.

Owner:慧科高新科技股份有限公司

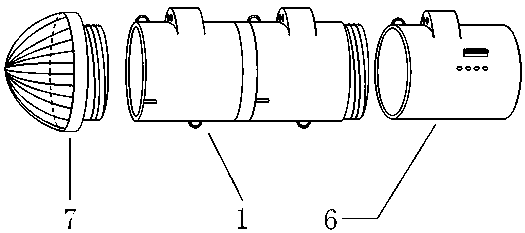

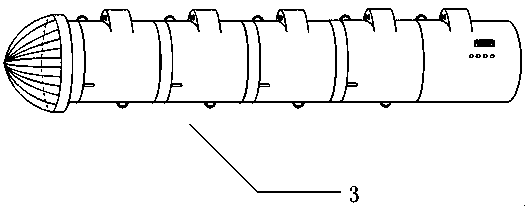

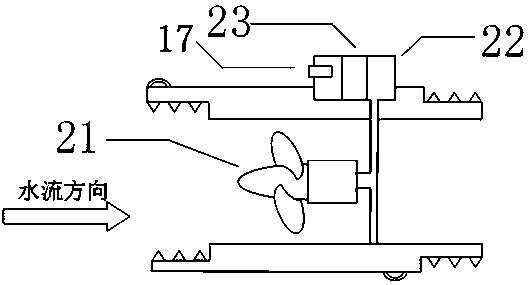

Combined type portable hydroelectric power generation device

PendingCN109026495AReduce rotational movementReduce lossesBatteries circuit arrangementsFinal product manufactureManufacturing technologyComputer module

The invention discloses a combined type portable hydroelectric power generation device, and provides a power generation device which is reasonable in design, low in manufacturing cost and convenient to maintain. The potential energy of water flow in rivers in the natural world can be converted into the electric energy, the modular design is adopted, combined modules can be freely replaced, and a flow guide net module is creatively added and used for eliminating the rotary movement of liquid flow. The power generation device, except assemblies of the necessary part, is made of materials which are small in mass and simple in manufacturing technology, such as PE. The combined type portable hydroelectric power generation device adopts the modular design, can achieve free combination and replacement of the assemblies and is easy to maintain, and the effectiveness of the power generation device can be guaranteed to the maximum extent under the condition that the natural environment is severe.

Owner:NANJING INST OF TECH

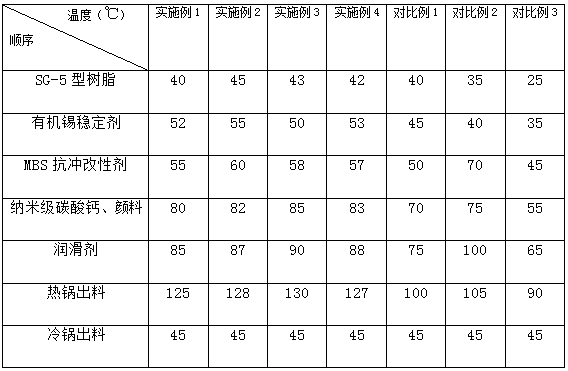

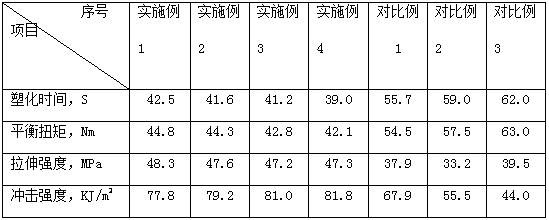

A compound capable of improving the quality and processability of PVC-M pipes and its preparation method

The invention discloses a compound capable of improving quality and processability of a PVC-M pipe and a preparation method of the compound. The compound is prepared from raw materials in parts by weight as follows: 100-120 parts of PVC resin, 0.4-1.0 part of a heat stabilizer, 3-8 parts of an impact modifier, 1.0-3.0 parts of a lubricant, 3.0-8.0 parts of a filling agent and 0.2-1.0 part of a colorant. During preparation, all components are added in a specific order at different temperature intervals step by step, and the prepared compound is stable in performance, short in plasticizing time, low in balance torque and uniform in material dispersity, and volatile matter is more thoroughly volatized. The impact-resistant PVC pipe made from the compound and used for water supply has high physical and mechanical performance, mechanical performance is greatly improved, the performance of the pipe can be kept stable, the compound has the appearance density of 0.55-0.60 g / ml, and the pipe has the tensile strength of 47.3-48.3 MPa, impact strength of 77.8-81.8 KJ / m<3>, plasticizing time of 39.0-42.5 S and balance torque of 42.1-44.8 Nm. The preparation method of the compound is simple and easy to control and facilitates actual production, and the production can be kept stable and efficient.

Owner:GANSU QINGLONG PIPE IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com