Environmental-friendly high-efficiency composite heat stabilizer for tribasic zinc PVC (polyvinyl chloride) and preparation method of environmental-friendly high-efficiency composite heat stabilizer

A technology of composite heat stabilizer and auxiliary heat stabilizer, applied in the preparation of alcohol metal, organic chemistry, etc., can solve the limitation of the popularization and application of non-toxic zinc-based heat stabilizer, high cost, unsatisfactory heat stabilization effect of heat stabilizer, etc. problem, to achieve good initial colorability, improved processing performance, and good stabilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

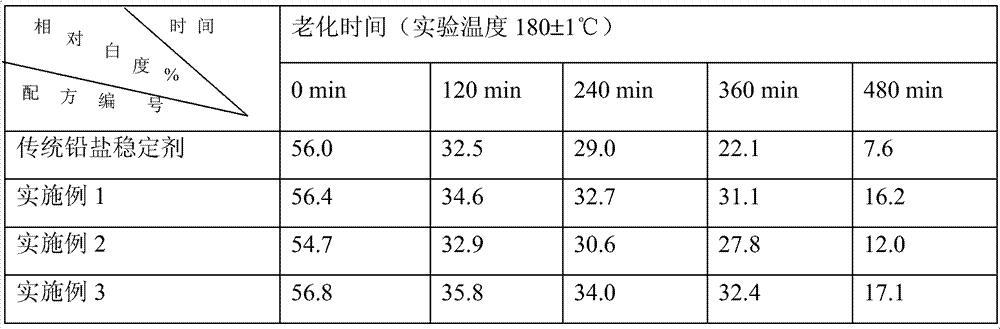

Examples

Embodiment 1

[0020] Weigh pentaerythritol and zinc oxide according to the mass ratio of 7:3, pulverize the two fully and mix them, heat to 180°C, stir while heating, react for 4 hours, take out the materials and cool them, and obtain zinc trisalt after pulverization.

[0021] First add 34 parts by mass of zinc trisalt and 28 parts by mass of calcium stearate into the reaction kettle and mix them well, take the mixed material, put it into a kneader and knead it at 110°C for 20 minutes, then add 30 parts by mass of lubricant hard Fatty acid and 8 parts by mass of auxiliary heat stabilizer stearoylbenzoylmethane were kneaded and stirred for 25 minutes, discharged into tablets, sieved and packaged to obtain the final product.

Embodiment 2

[0023] Weigh pentaerythritol and zinc oxide according to the mass ratio of 6:3, pulverize and mix them fully, heat to 150°C, stir while heating, and react for 5.5 hours, take out the materials and cool them, and after pulverization, zinc trisalt is obtained.

[0024] First add 40 parts by mass of zinc trisalt and 30 parts by mass of calcium stearate into the reaction kettle and mix well, take the mixed material, put it into a kneader and knead it at 120°C for 25 minutes, then add 20 parts by mass of lubricant polymer to the kneader Ethylene wax and 10 parts by mass of auxiliary heat stabilizer dibenzoylmethane were kneaded and stirred for 30 minutes, discharged into tablets, sieved and packaged to obtain the final product.

Embodiment 3

[0026] Weigh pentaerythritol and zinc oxide according to the mass ratio of 8:3, pulverize and mix them thoroughly, heat to 160°C, stir while heating, and react for 5 hours, take out the materials and cool them, and obtain zinc trisalt after pulverization.

[0027] First add 45 parts by mass of zinc trisalt and 25 parts by mass of calcium stearate into the reaction kettle and mix thoroughly, take the mixed material, put it into a kneader and knead it at 120°C for 18 minutes, then add 25 parts by mass of lubricant polymer to the kneader Ethylene wax and 5 parts by mass of auxiliary heat stabilizer dibenzoylmethane were kneaded and stirred for 32 minutes, discharged into tablets, sieved and packaged to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com