CPVC (Chlorinated Polyvinyl Chloride) composition with good heat stability and preparation method thereof

A CPVC resin and thermal stability technology, which is applied in the field of CPVC composition with good thermal stability and its preparation, can solve problems such as CPVC processing difficulties, achieve long dynamic thermal stability time, solve processing difficulties, and meet production needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

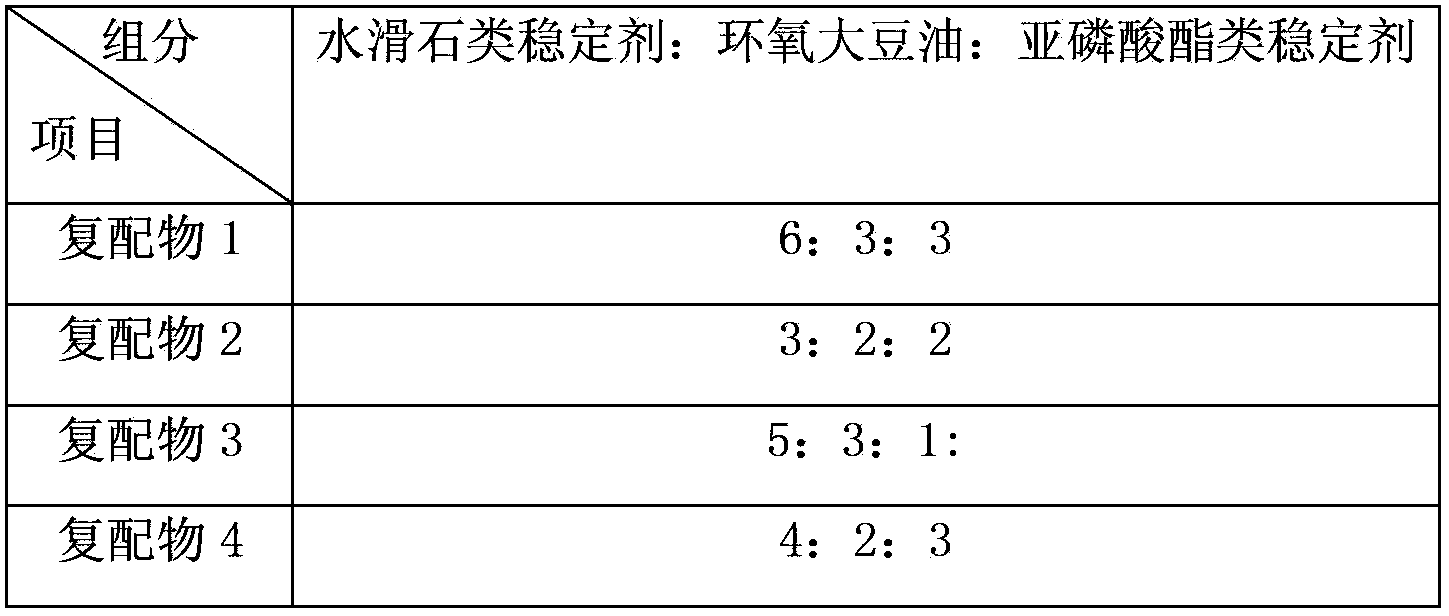

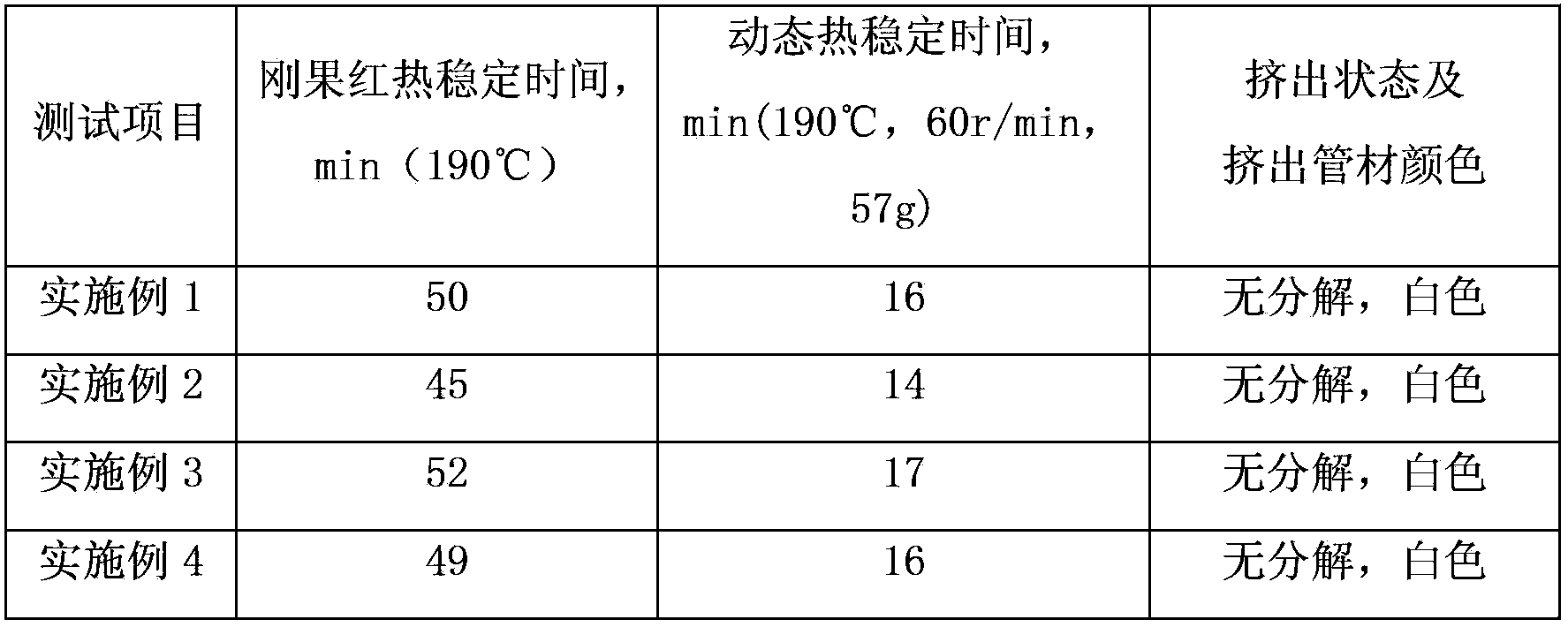

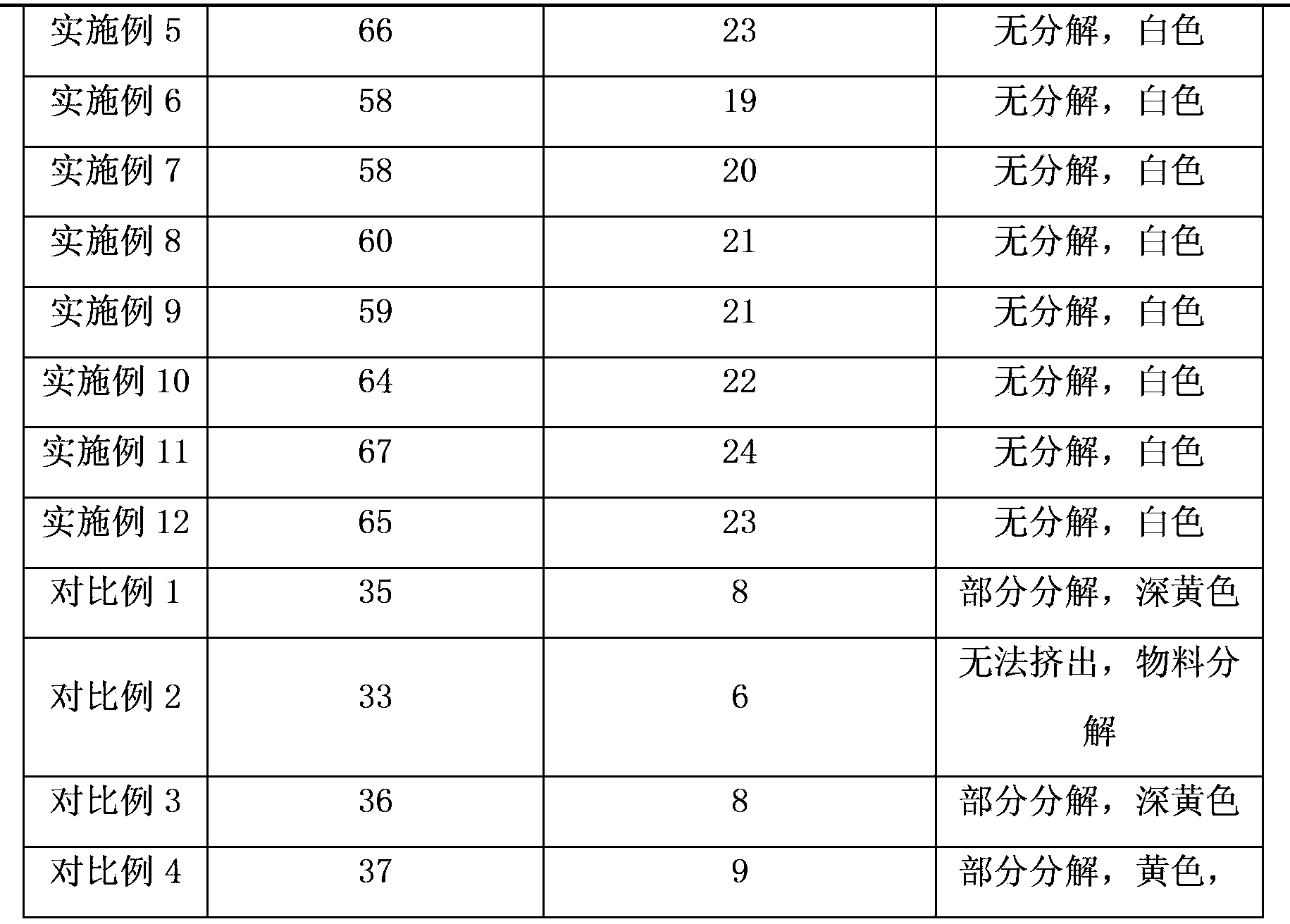

[0019] Examples 1-12 are specific examples of the CPVC composition with good thermal stability of the present invention. Wherein embodiment 8 is the best implementation mode. In Examples 1 to 12, the composition ratio of the compound is shown in Table 1:

[0020] The mass ratio of each component in the compound of table 1

[0021]

[0022] In embodiment 1~12, the preparation method of composite stabilizer is as follows:

[0023] 1) Preparation of the compound: according to the mass ratio shown in Table 1, put the hydrotalcite stabilizer into the high-speed mixer, mix and heat up to 80-110°C, then gradually add epoxy soybean oil dropwise in proportion (among them, compound After compound 1 is heated to 110°C, compound 2 is heated to 80°C, compound 3 is heated to 100°C, and compound 4 is heated to 90°C, epoxy soybean oil is added dropwise); After the soybean oil is uniformly absorbed by the hydrotalcite stabilizer, the phosphite stabilizer is gradually added dropwise in pr...

Embodiment 1

[0026] 100 parts of CPVC resin, wherein the degree of polymerization of PVC is 700, and the chlorine content is 64%;

[0027] Composite stabilizer 3 parts, choose compound 1 and tin methyl mercaptide to mix according to the mass ratio of 1:1;

[0028] 8 parts of impact modifier CPE135A are selected;

[0029] The internal lubricant fatty acid lower alcohol ester G-16 is selected from 0.5 parts;

[0030] The external lubricant oxidized polyethylene wax AC-316A is selected as 0.8 parts;

[0031] 3 parts of titanium dioxide.

Embodiment 2

[0033] 100 parts of CPVC resin, wherein the degree of polymerization of PVC is 700, and the chlorine content is 64%;

[0034] Composite stabilizer 3 parts, choose compound 1 and tin methyl mercaptide to mix according to the mass ratio of 1:1;

[0035] 8 parts of impact modifier CPE135A are selected;

[0036] The internal lubricant fatty acid lower alcohol ester G-16 is selected from 0.5 parts;

[0037] The external lubricant oxidized polyethylene wax AC-316A is selected as 0.8 parts;

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com