Outside sealing strip of automobile window and manufacturing method thereof

A technology for sealing strips and windows, applied in sealing devices, engine sealing, mechanical equipment, etc., can solve the problems of poor impact resistance of window sealing strips, achieve light weight, improve impact strength, and more plasticized effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

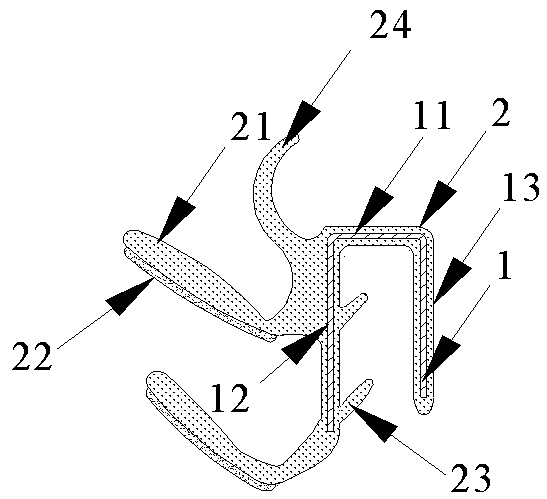

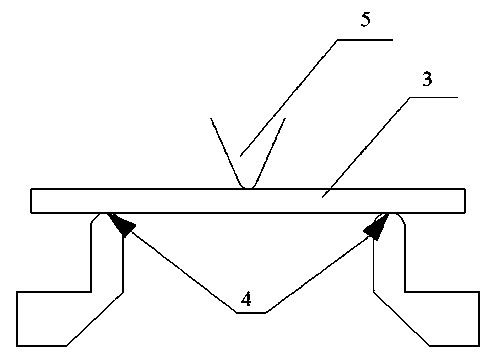

[0022] The invention provides a method for preparing a car window sealing strip. The method is to co-extrude the alloy plastic formed by chlorinated polyvinyl chloride and acrylonitrile-butadiene-styrene copolymer and polyvinyl chloride, wherein the The above polyvinyl chloride completely covers the alloy plastic formed by chlorinated polyvinyl chloride and acrylonitrile-butadiene-styrene copolymer, and then pastes the flannelette on the side where the first protrusion is in contact with the window glass. The glue at the bottom of the flannelette is melted and bonded to the soft side of the PVC substrate, and is completely cured and pasted after being shaped by the falling water setting mold and cooled in water.

[0023] Preferably, the alloy plastic formed by the chlorinated polyvinyl chloride and the acrylonitrile-butadiene-styrene copolymer and the polyvinyl chloride co-extruded method are chlorinated polyvinyl chloride and acrylonitrile-butadiene - The raw materials of all...

Embodiment 1

[0029] The total amount of alloy plastics of chlorinated polyvinyl chloride (CPVC) and acrylonitrile-butadiene-styrene copolymer (ABS) is 100 parts, of which the amount of ABS is 12.5 parts; the chlorinated polyvinyl chloride (CPVC) and The raw materials of acrylonitrile-butadiene-styrene copolymer (ABS) alloy plastic and polyvinyl chloride are respectively fed into two extruders for extrusion molding, and the segmental heating temperature of CPVC / ABS is about 185°C; The staged heating temperature is 110°C. Wherein the polyvinyl chloride completely covers the alloy plastic skeleton, and then sticks the flannelette on the side where the first protrusion is in contact with the window glass, melts the glue at the bottom of the flannelette at high temperature and bonds it with the soft side of the PVC substrate, and then it is shaped by falling water After shaping the mold and cooling in water, it is completely solidified and pasted to prepare the sealing strip A1. The raw materi...

Embodiment 2

[0031] Sealing strip A2 was prepared according to the method in Example 1. The difference is: the amount of ABS is 25 parts; there is no second protrusion, the thickness of the skeleton is 0.5cm; the thickness of the burrs is 0.8mm, the length is 3.5mm, and the angle is 130°. The thickness of the first protrusion is 2.3 mm, the length is 13.5 mm, and the angle is 115°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com