High-toughness flame-retardant cable for electric power circuit and preparation process of cable

A technology for flame-retardant cables and power lines, which is applied to circuits, electrical components, plastic/resin/wax insulators, etc. It can solve the problems of low strength of silicone rubber cables, failure to meet power circuits, poor toughness, etc., and achieve high hardness, Effect of good processability, high dielectric constant and breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

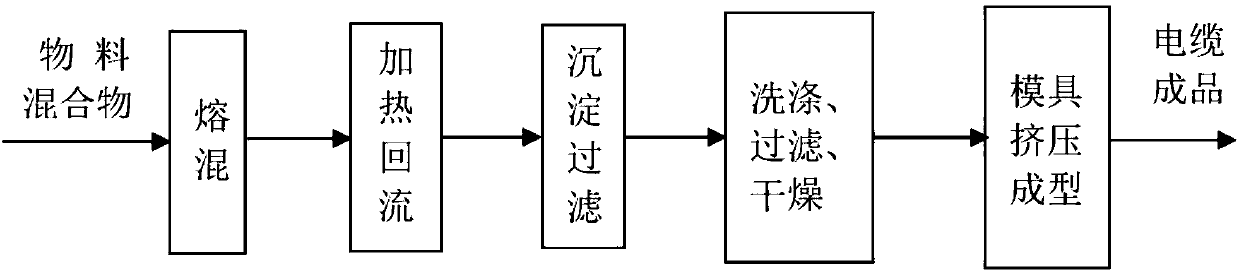

Method used

Image

Examples

Embodiment 1

[0021] 80 parts of hydrogenated polystyrene-butadiene block copolymer, 80 parts of polypropylene, 4 parts of maleic anhydride, 12 parts of MCA flame retardant, 6 parts of diethyl aluminum hypophosphite, 7 parts of montmorillonite, silicone 2 parts of powder, 1 part of dicumyl peroxide, 2 parts of antioxidant.

[0022] The hydrogenated polystyrene-butadiene block copolymer takes butadiene and styrene as monomers, cyclohexane as solvent, n-butyllithium as initiator, tetrahydrofuran as activator, and silicon tetrachloride as The coupling agent is prepared by anionic polymerization to obtain the base rubber, and then hydrogenated with a cyanocatalyst.

[0023] The polypropylene is a crystalline polymer with regular structure, and the specific model is polypropylene T30S thermoplastic resin.

[0024] The montmorillonite is a kind of silicate natural mineral, containing Al 2 o 3 16.54%, MgO 4.65%, SiO 2 50.95%, is a typical intumescent flame retardant.

[0025] The silicone po...

Embodiment 2

[0032] 120 parts of hydrogenated polystyrene-butadiene block copolymer, 120 parts of polypropylene, 8 parts of maleic anhydride, 15 parts of MCA flame retardant, 10 parts of diethyl aluminum hypophosphite, 10 parts of montmorillonite, silicone 4 parts of powder, 2 parts of dicumyl peroxide, 4 parts of antioxidant.

[0033] The hydrogenated polystyrene-butadiene block copolymer takes butadiene and styrene as monomers, cyclohexane as solvent, n-butyllithium as initiator, tetrahydrofuran as activator, and silicon tetrachloride as The coupling agent is prepared by anionic polymerization to obtain the base rubber, and then hydrogenated with a cyanocatalyst.

[0034] The polypropylene is a crystalline polymer with regular structure, and the specific model is polypropylene T30S thermoplastic resin.

[0035] The montmorillonite is a kind of silicate natural mineral, containing Al 2 o 3 16.54%; MgO 4.65%; SiO 2 50.95%, is a typical intumescent flame retardant.

[0036] The silico...

Embodiment 3

[0043] 100 parts of hydrogenated polystyrene-butadiene block copolymer, 100 parts of polypropylene, 6 parts of maleic anhydride, 13 parts of MCA flame retardant, 8 parts of diethyl aluminum hypophosphite, 9 parts of montmorillonite, silicone 3 parts of powder, 1.5 parts of dicumyl peroxide, 3 parts of antioxidant.

[0044] The hydrogenated polystyrene-butadiene block copolymer takes butadiene and styrene as monomers, cyclohexane as solvent, n-butyllithium as initiator, tetrahydrofuran as activator, and silicon tetrachloride as The coupling agent is prepared by anionic polymerization to obtain the base rubber, and then hydrogenated with a cyanocatalyst.

[0045] The polypropylene is a crystalline polymer with regular structure, and the specific model is polypropylene T30S thermoplastic resin.

[0046] The montmorillonite is a kind of silicate natural mineral, containing Al 2 o 3 16.54%, MgO 4.65%, SiO 2 50.95%, is a typical intumescent flame retardant.

[0047] The silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com