Low energy consumption and high extrusion output pvc-m pipe composition

A technology with low energy consumption and composition, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of high energy consumption, high extrusion output, high energy consumption, difficulty in extrusion of PVC-M pipes, etc. The effect of improved mechanical properties, high mechanical properties, good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

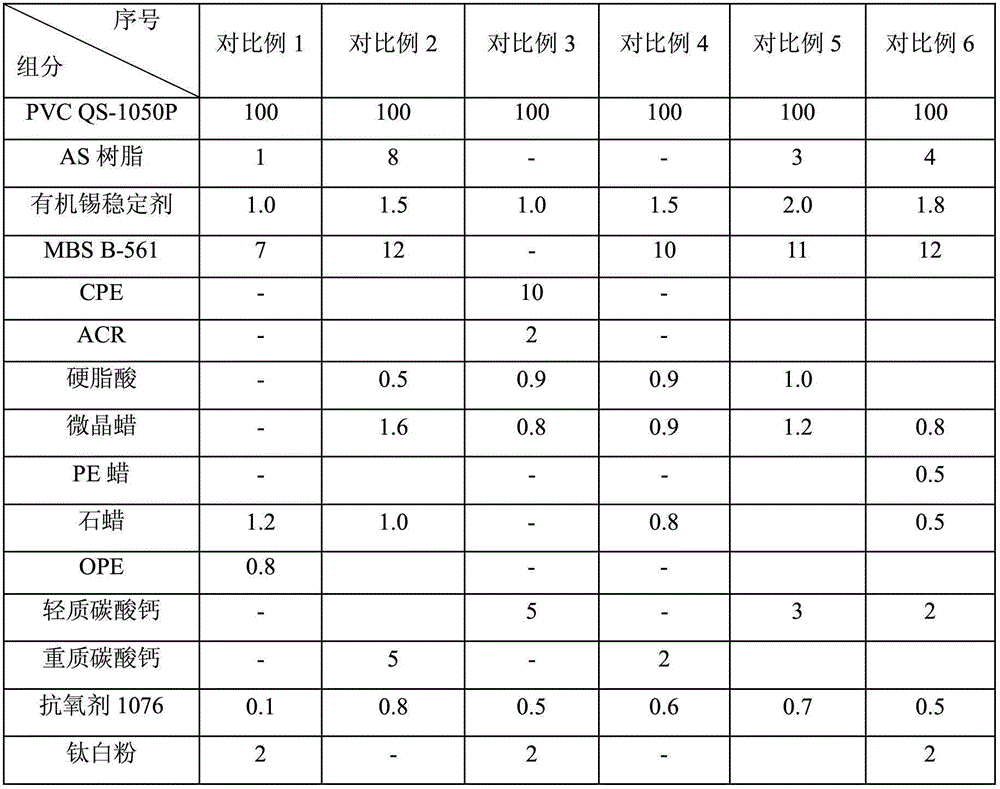

[0021] Examples 1 to 12 are the proportioning components of the PVC-M pipe composition with low energy consumption and high extrusion output of the present invention, as shown in Table 1 and Table 2. The PVC resin used in Examples 1-12 is the PVCQS-1050P pipe special resin produced by Qilu Petrochemical Company, and its degree of polymerization is 1000. Wherein embodiment 3 is the best implementation mode.

[0022] Table 1 Embodiment 1~6 Low energy consumption and high extrusion output PVC-M pipe composition (by weight)

[0023]

[0024] Table 2 Embodiment 7-12 Low energy consumption and high extrusion output PVC-M pipe composition (by weight)

[0025]

[0026] The preparation method of embodiment 1~12, carry out as follows:

[0027] a) Put PVC resin, processed modified resin, heat stabilizer, toughener, hindered phenolic antioxidant, lubricant, filler, and colorant into a high-speed mixer for stirring and mixing, and the stirring speed of the high-speed mixer is 1000~...

Embodiment 2

[0058] Table 13 Example 2 Performance test typical value

[0059] project

technical indicators

Test results

0℃ drop weight impact test, TIR

≤5%

1%

Hydraulic test (ring stress 38MPa at 20°C, 1h)

No cracks, no leaks

No cracks, no leaks

Hydraulic test (60°C ring stress 10MPa, 1000h)

No cracks, no leaks

No cracks, no leaks

80℃

82℃

Longitudinal retraction

≤5%

2%

[0060] Table 14 is that the embodiment of the present invention 2 produces The PVC-M pipe material and comparative example 3 produced According to the comparative results of longitudinal shrinkage of PVC-M pipes, it can be seen that the extrusion speed of the composition pipe of the present invention is improved, but the longitudinal shrinkage is not increased, and all properties meet the requirements of pipe standards.

[0061] Table 14 Longitudinal shrinkage of impact-resistant PVC-M pipes

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com