A compound capable of improving the quality and processability of PVC-M pipes and its preparation method

A technology of processability and PVC resin, which is applied in the field of compounding materials and its preparation that can improve the quality and processability of PVC-M pipes, and can solve the problems of restricting the market value of PVC-M pipes, uneven product quality, and difficulty in product molding, etc. problems, to achieve stable and efficient production, uniform material dispersion, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

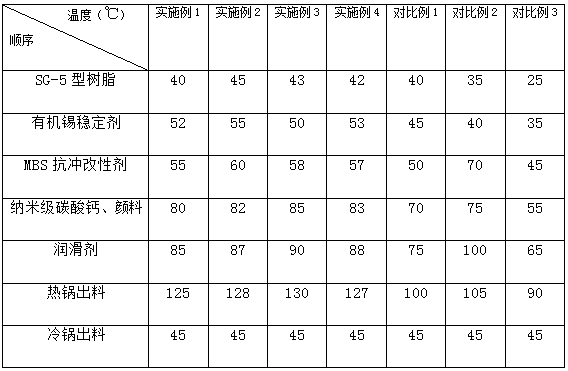

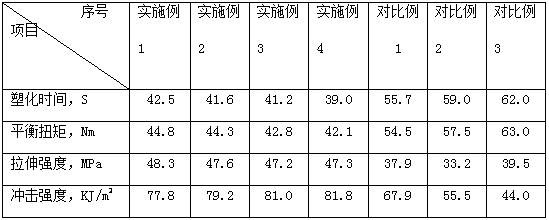

Embodiment 1

[0024] A compounding ingredient that can improve the quality and processability of PVC-M pipes, which is composed of the following raw materials in parts by weight: 100 parts of SG-5 resin; 0.8 parts of organic tin stabilizer; 6 parts of MBS impact modifier; 1.8 parts of stearic acid; 5 parts of nanometer calcium carbonate; 0.5 parts of pigments.

[0025] The preparation method of the compound which can improve the quality and processability of PVC-M pipe includes the following steps:

[0026] A. Start the high-speed mixer, the stirring speed is 1000-2000 rpm, when the hot pot temperature of the high-speed mixer reaches 40 ℃, put SG-5 resin into the hot pot;

[0027] B. When the temperature of the hot pot reaches 52℃, put the organotin stabilizer into the hot pot;

[0028] C. When the temperature of the hot pot reaches 55°C, put MBS impact modifier into the hot pot;

[0029] D. When the temperature of the hot pot reaches 80°C, put nanometer calcium carbonate and pigments into the hot p...

Embodiment 2

[0034] A compounding ingredient that can improve the quality and processability of PVC-M pipes, which is composed of the following raw materials in parts by weight: 120 parts by weight of SG-5 resin; 1 part of organic tin stabilizer; 3 parts of MBS impact modifier; 3 parts of microcrystalline wax; 8 parts of nanometer calcium carbonate; 0.2 parts of pigments.

[0035] The preparation method of the compound which can improve the quality and processability of PVC-M pipe includes the following steps:

[0036] A. Start the high-speed mixer, the stirring speed is 1000-2000 rpm, when the hot pot temperature of the high-speed mixer reaches 45°C, put SG-5 resin into the hot pot;

[0037] B. When the temperature of the hot pot reaches 55°C, put the organotin stabilizer into the hot pot;

[0038] C. When the temperature of the hot pot reaches 60°C, put MBS impact modifier into the hot pot;

[0039] D. When the temperature of the hot pot reaches 82°C, put nanometer calcium carbonate and pigments ...

Embodiment 3

[0044] A blending ingredient that can improve the quality and processability of PVC-M pipes, which is composed of the following raw materials in parts by weight: 110 parts by weight of SG-5 resin; 0.4 parts of organic tin stabilizer; 8 parts of MBS impact modifier; 1 part of stearic acid and microcrystalline wax; 3 parts of nanometer calcium carbonate; 1 part of pigment.

[0045] The preparation method of the compound which can improve the quality and processability of PVC-M pipe includes the following steps:

[0046] A. Start the high-speed mixer, the stirring speed is 1000-2000 rpm, when the temperature of the hot pot of the high-speed mixer reaches 43℃, put SG-5 resin into the hot pot;

[0047] B. When the temperature of the hot pot reaches 50℃, put the organotin stabilizer into the hot pot;

[0048] C. When the temperature of the hot pot reaches 58°C, put MBS impact modifier into the hot pot;

[0049] D. When the temperature of the hot pot reaches 85°C, put nanometer calcium carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com