PVC (polyvinyl chloride) modified material for industrial peelable wire and preparation method of modified material

A modified material, PVC resin technology, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of easy tearing, poor thermal stability, poor fluidity, etc. The effect of stable performance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

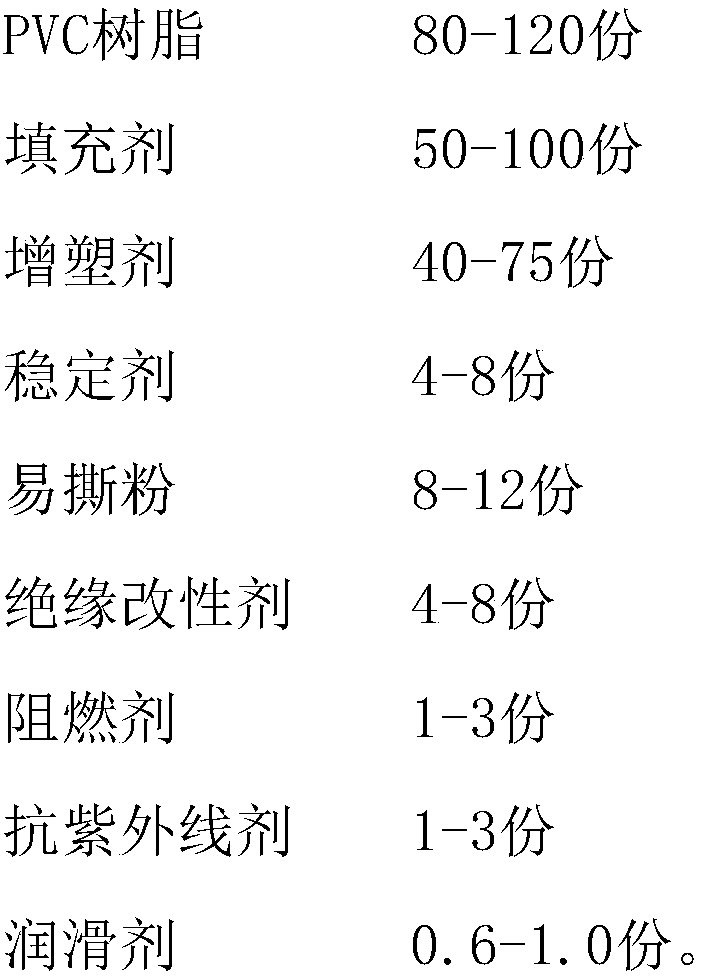

Method used

Image

Examples

Embodiment 1

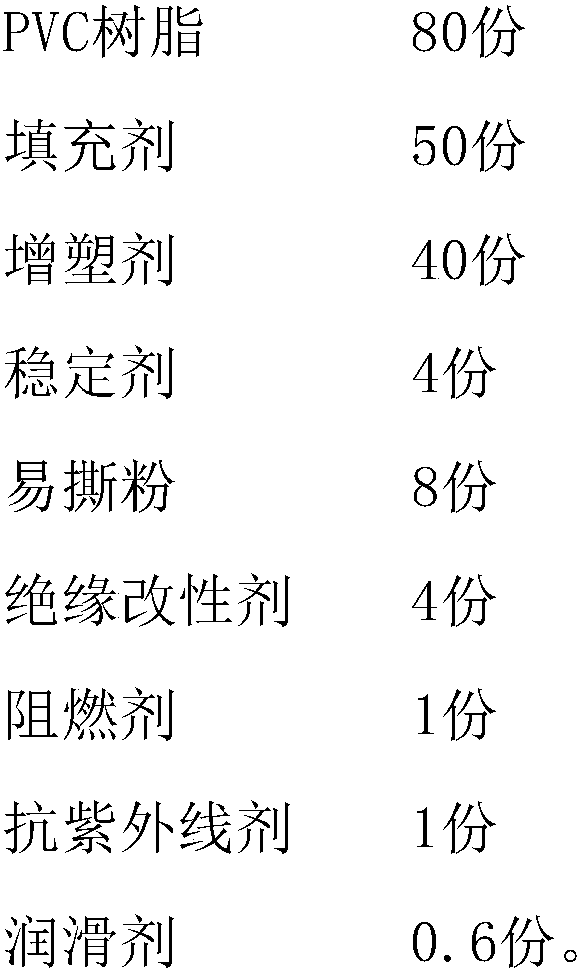

[0039] A PVC modified material for industrial easy-to-tear wires, comprising the following raw materials in parts by weight:

[0040]

[0041] The PVC resin is an ethylene-based PVC resin with an average degree of polymerization of 900.

[0042] The filler is heavy calcium carbonate with a particle size of 1 μm and modified by silane coupling agent and maleic anhydride grafted polypropylene.

[0043] The preparation method of the plasticizer is: weighing 20 parts of cage-type organosilicon hybrid star polyester, 15 parts of 2-hydroxy triglyceride stearate, and 15 parts of diethylene glycol dibenzoate in parts by weight. , 10 parts of epoxy fatty acid methyl ester, 20 parts of polyhydroxyvaleric acid, 15 parts of terephthalic acid, 10 parts of ricinoleic acid, 20 parts of diethylene glycol, 15 parts of polyvinyl alcohol, 10 parts of xylitol, chitin 5 parts, 8 parts of epoxidized soybean oil and 3 parts of carbonamide, mixed, stirred and reacted at 250°C for 60 minutes.

[...

Embodiment 2

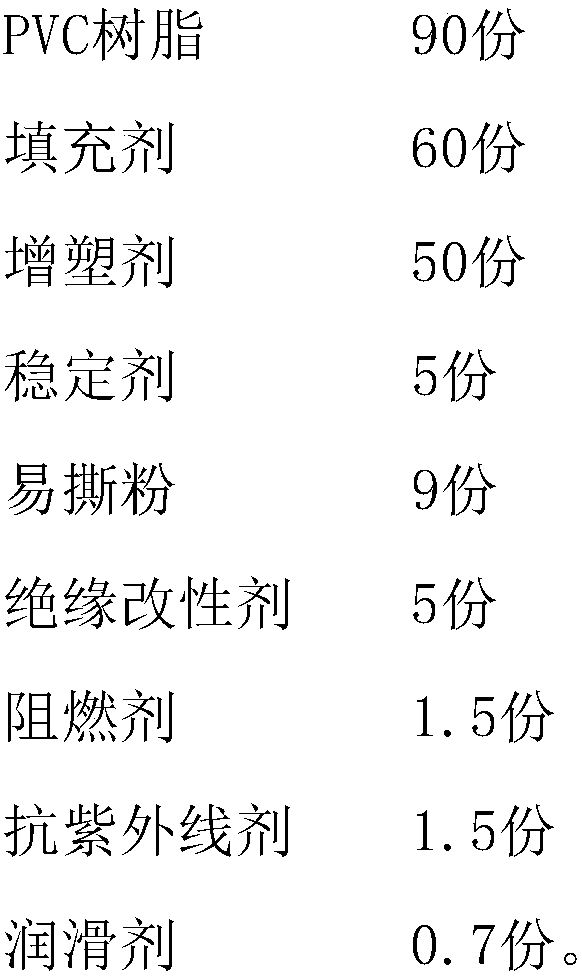

[0053] A PVC modified material for industrial easy-to-tear wires, comprising the following raw materials in parts by weight:

[0054]

[0055] The PVC resin is an ethylene-based PVC resin with an average degree of polymerization of 950.

[0056] The filler is heavy calcium carbonate with a particle size of 3 μm and modified by silane coupling agent and maleic anhydride grafted polypropylene.

[0057] The preparation method of the plasticizer is: weighing 25 parts of cage-type organosilicon hybrid star polyester, 18 parts of 2-hydroxystearic acid triglyceride, and 18 parts of diethylene glycol dibenzoate in parts by weight. , 12 parts of epoxy fatty acid methyl ester, 22 parts of polyhydroxyvaleric acid, 18 parts of terephthalic acid, 12 parts of ricinoleic acid, 22 parts of diethylene glycol, 18 parts of polyvinyl alcohol, 12 parts of xylitol, chitin 8 parts, 9 parts of epoxidized soybean oil and 3.5 parts of carbonamide, mixed, stirred and reacted at 280°C for 50 minutes....

Embodiment 3

[0067] A PVC modified material for industrial easy-to-tear wires, comprising the following raw materials in parts by weight:

[0068]

[0069] The PVC resin is an ethylene-based PVC resin with an average degree of polymerization of 1000.

[0070] The filler is heavy calcium carbonate with a particle size of 5 μm and modified by silane coupling agent and maleic anhydride grafted polypropylene.

[0071] The preparation method of the plasticizer is: weighing 30 parts of cage-type organosilicon hybrid star polyester, 20 parts of 2-hydroxystearic acid triglyceride, and 20 parts of diethylene glycol dibenzoate in parts by weight. , 15 parts of epoxy fatty acid methyl ester, 25 parts of polyhydroxyvaleric acid, 20 parts of terephthalic acid, 15 parts of ricinoleic acid, 25 parts of diethylene glycol, 20 parts of polyvinyl alcohol, 15 parts of xylitol, chitin 10 parts, 10 parts of epoxidized soybean oil and 4 parts of carbonamide, mixed, stirred and reacted at 300°C for 45 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com