Composite PVC stabilizer

A technology of stabilizer and auxiliary heat stabilizer, applied in the field of composite PVC stabilizer, can solve the problems of high melting point of polyol, inconvenience of polyol, "zinc burning", etc., achieve good color, improve processing performance, and reduce balance torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

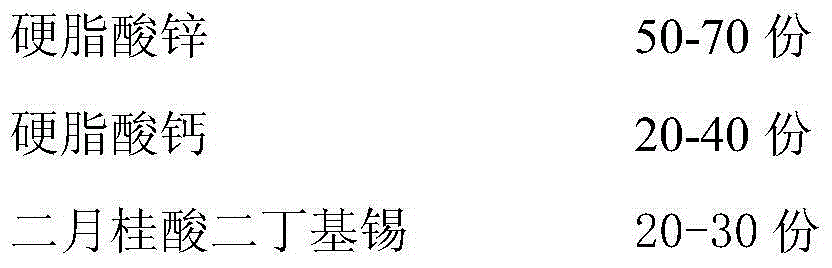

[0015] Composite PVC stabilizer is made from the following raw materials in parts by mass:

[0016]

[0017] The β-diketone is dibenzoylmethane.

[0018] Described lubricant selects stearic acid or polyethylene wax.

[0019] Described auxiliary thermal stabilizer selects epoxidized soybean oil.

Embodiment 2

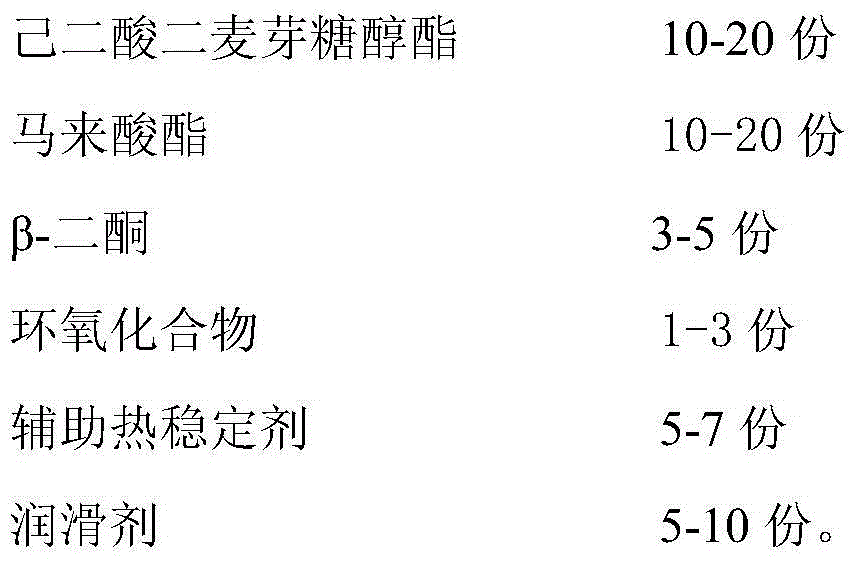

[0021] Composite PVC stabilizer is made from the following raw materials in parts by mass:

[0022]

[0023] The β-diketone is selected from stearoylbenzoylmethane.

[0024] Described lubricant selects polyethylene wax.

[0025] Described auxiliary thermal stabilizer selects epoxidized soybean oil.

Embodiment 3

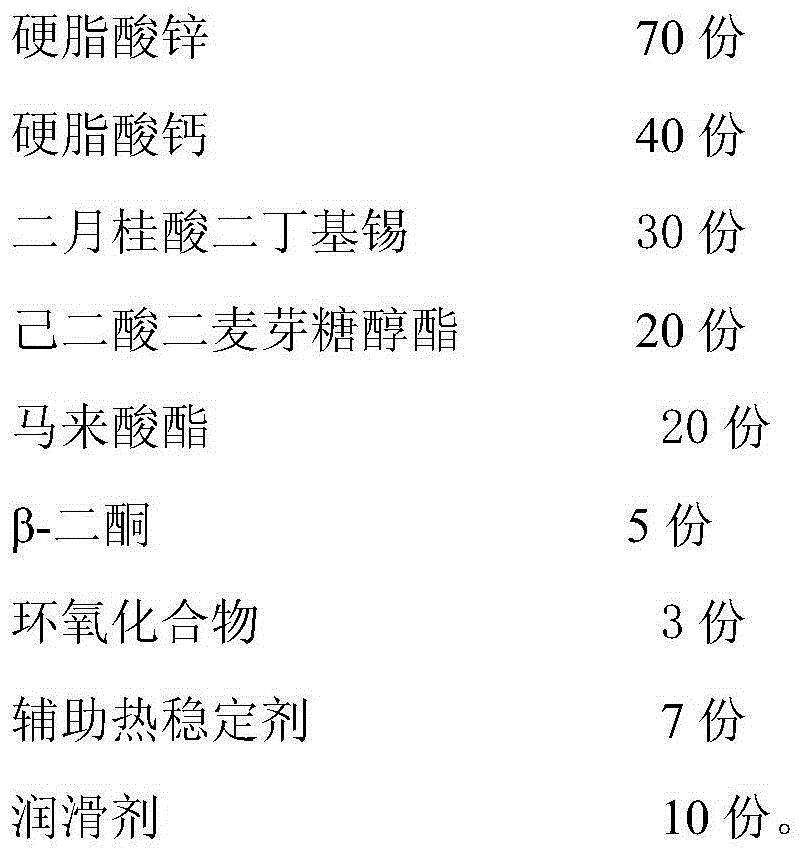

[0027] Composite PVC stabilizer is made from the following raw materials in parts by mass:

[0028]

[0029] The β-diketone is dibenzoylmethane.

[0030] Described lubricant selects stearic acid.

[0031] Described auxiliary thermal stabilizer selects epoxidized soybean oil.

[0032] Three kinds of composite thermal stabilizers of above-mentioned embodiment 1, 2 and 3 are added in 100 mass parts PVC respectively by 4 mass parts, then add 20 mass parts calcium carbonate, 5 mass parts TiO 2 1. 1 part by mass of stearic acid was kneaded by two rolls at 180° C. for 5 minutes to prepare a flaky sample with a thickness of 1 mm.

[0033] Table 1 Congo red experiment

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com