Star-structure fluorine-containing phosphazene flow modifier and preparation method and application thereof

A technology of flow modifier and fluorine-containing phosphazene, which is applied in the field of flow modifier, can solve the problems of no improvement in the flame retardant performance of composite materials, limited processing flow performance, large molecular weight, etc., and achieves improved processing flow performance and dispersibility. The effect of improving and reducing the viscosity of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

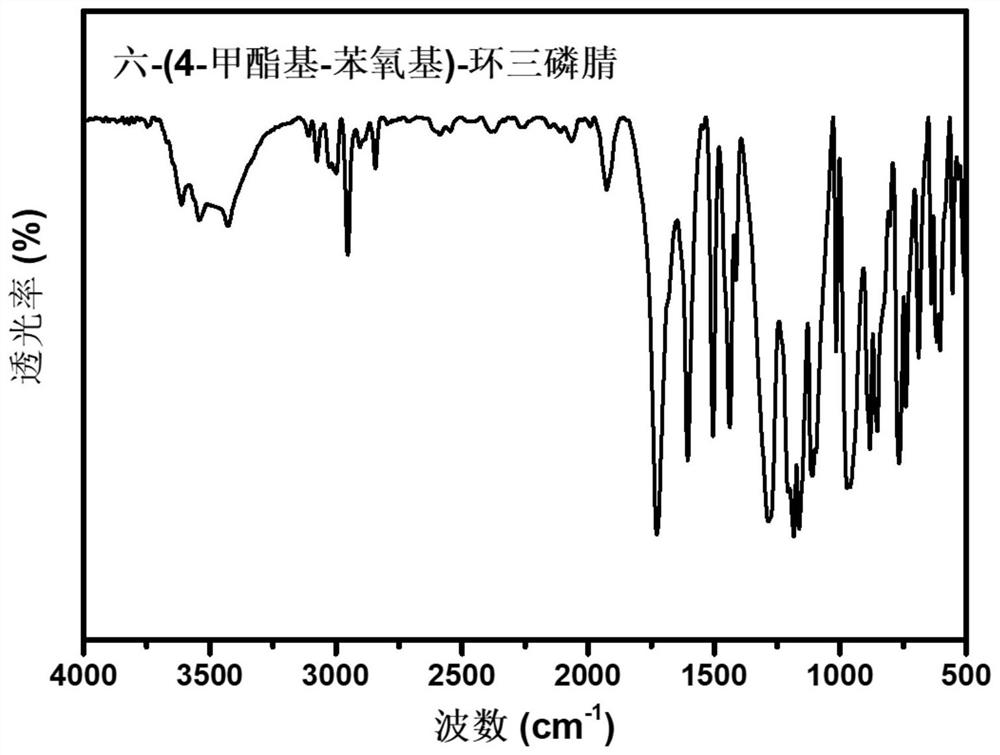

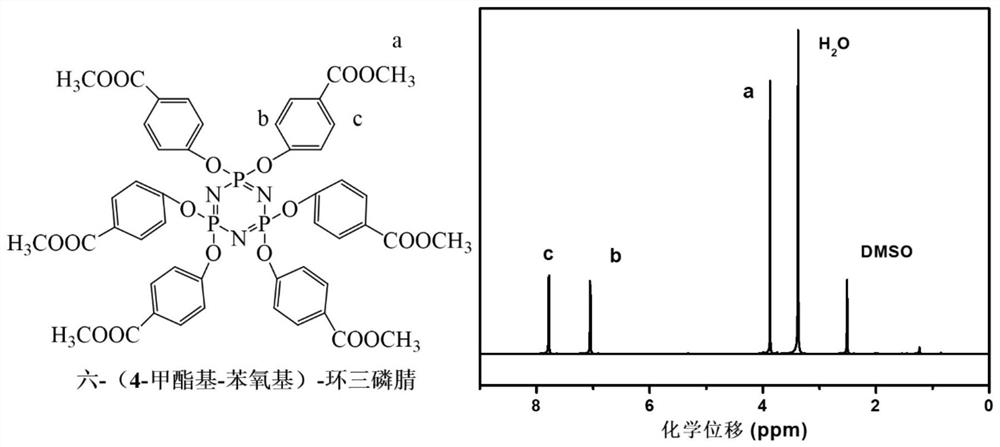

[0037] (1) Take 3.47g of hexachlorocyclotriphosphazene, 10.64g of methylparaben and 178mL of acetone in a 250ml three-neck flask, heat to 65°C, add 11.04g of potassium carbonate and react for 72h, cool, filter with suction, and place Dry in a vacuum oven at 70°C for 24 hours to obtain 8.15 g of a white solid product, which is hexa-(4-methoxy-phenoxy)-cyclotriphosphazene, with a yield of 57.8%;

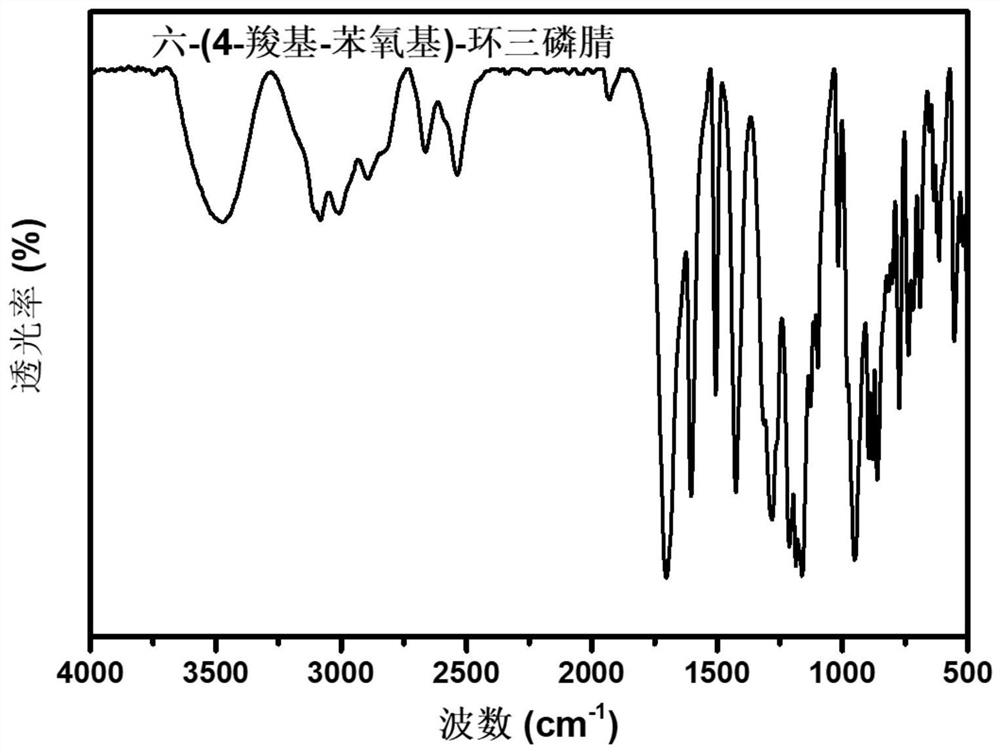

[0038] (2), take 6.76g hexa-(4-carbocarboxylate-phenoxy)-cyclotriphosphazene and 145mL of methanol into a 250mL three-necked flask equipped with a condenser tube and a magnetic stirrer, then add 23mL of deionized water, React at 60°C for 9h under stirring, after cooling, adjust the pH value to 2 with hydrochloric acid, a white precipitate precipitates out of the solution, filter it with suction, and dry it in a vacuum oven at 70°C for 6h to obtain 6.39g of a white solid product, which is hexa- (4-carboxy-phenoxy)-cyclotriphosphazene, the yield is 94.5%;

[0039] (3) Take 1.44g of hexa...

Embodiment 2

[0046] (1) Take 3.47g of hexachlorocyclotriphosphazene, 10.64g of methylparaben and 143mL of acetone in a 250ml three-neck flask, heat to 60°C, add 12.4g of potassium carbonate and react for 96h, cool, filter with suction, and place Dry in a vacuum oven at 65°C for 24 hours to obtain 8.11 g of a white solid product, which is hexa-(4-methoxy-phenoxy)-cyclotriphosphazene, with a yield of 64.4%;

[0047] (2), take 6.76g hexa-(4-methoxy-phenoxy)-cyclotriphosphazene and 144mL methanol into a 250mL three-necked flask equipped with a condenser tube and a magnetic stirrer, then add 24mL deionized water, React at 60°C for 8h under stirring, after cooling, adjust the pH value to 3 with hydrochloric acid, a white precipitate precipitates out of the solution, filter it with suction, and dry it in a vacuum oven at 60°C for 6h to obtain 6.52g of white solid product, which is hexa- (4-carboxy-phenoxy)-cyclotriphosphazene, the yield is 96.4%;

[0048] (3) Take 1.44g of hexa-(4-carboxy-phenox...

Embodiment 3

[0052] (1) Take 3.47g of hexachlorocyclotriphosphazene, 9.12g of methylparaben and 115mL of tetrahydrofuran in a 250ml three-necked flask, heat to 70°C, add 11.04g of potassium carbonate and react for 72h, cool, filter with suction, and place Dry in a vacuum oven at 65°C for 24 hours to obtain 8.23 g of a white solid product, which is hexa-(4-methoxy-phenoxy)-cyclotriphosphazene, with a yield of 65.4%;

[0053] (2), take 6.76g hexa-(4-carbocarboxylate-phenoxy)-cyclotriphosphazene and 150mL of methanol into a 250mL three-necked flask equipped with a condenser tube and a magnetic stirrer, then add 25mL of deionized water, React at 70°C for 9h under stirring, after cooling, adjust the pH value to 2 with hydrochloric acid, a white precipitate precipitates out of the solution, filter it with suction, and dry it in a vacuum oven at 65°C for 6h to obtain 6.48g of a white solid product, which is hexa- (4-carboxy-phenoxy)-cyclotriphosphazene, the yield is 95.9%;

[0054] (3) Take 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com