Organic complex zinc composite heat stabilizer for PVC and preparation method thereof

A composite heat stabilizer and organic complexing technology, which is applied in the field of PVC processing aids, can solve the problem that the thermal stability of calcium/zinc heat stabilizers cannot meet the application requirements, limit the application field of calcium/zinc composite heat stabilizers, reduce the Operability and other issues, to achieve good stability, reduce balance torque, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

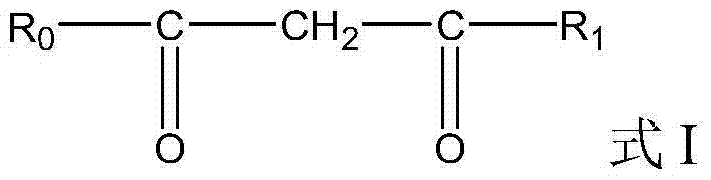

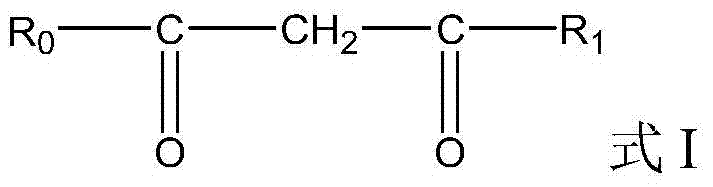

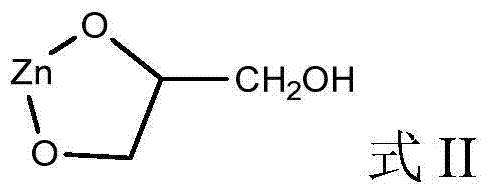

[0032] Put 17g of zinc carbonate and 100mL of absolute ethanol into a flask equipped with condensing reflux, heat to reflux, add 60g of dibenzoylmethane to the solution, and react at reflux for 2h. After the reaction is complete, unreacted zinc carbonate is removed by filtration, and the filtrate is cooled to obtain pale yellow needle-shaped organic complex zinc.

[0033] 50g of organic complex zinc, 60g of calcium stearate and 10g of stearic acid are mixed to obtain composite thermal stabilizer A.

Embodiment 2

[0035] Put 86g of zinc stearate and 200mL of ethanol into a flask equipped with condensing reflux, heat to reflux, add 60g of dibenzoylmethane to the solution, and react under reflux for 3h. After the reaction is complete, unreacted zinc stearate is removed by filtration, and the filtrate is cooled to obtain pale yellow needle-shaped organic complex zinc.

[0036] 50g of organic complex zinc, 60g of calcium stearate, and 3g of sorbitol were mixed to obtain composite thermal stabilizer B.

Embodiment 3

[0038] Put 25g of zinc acetate and 100mL of methanol into a flask equipped with condensing reflux, heat to reflux, add 60g of dibenzoylmethane to the solution, and react at reflux for 3h. After the reaction is complete, unreacted zinc stearate is removed by filtration, and the filtrate is cooled to obtain pale yellow needle-shaped organic complex zinc.

[0039] 50g of organic complex zinc, 60g of calcium stearate and 12g of hydrotalcite were mixed to obtain composite thermal stabilizer C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com