Environmental protection PVC section bar organic tin stabilizing agent

An organotin and stabilizer technology, applied in the field of organotin stabilizers for environmentally friendly PVC profiles, can solve the problems of not being able to be the main stabilizer alone, low thermal stability, poor coloring, etc., to achieve reduced balance torque, good thermal stability and Processability and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

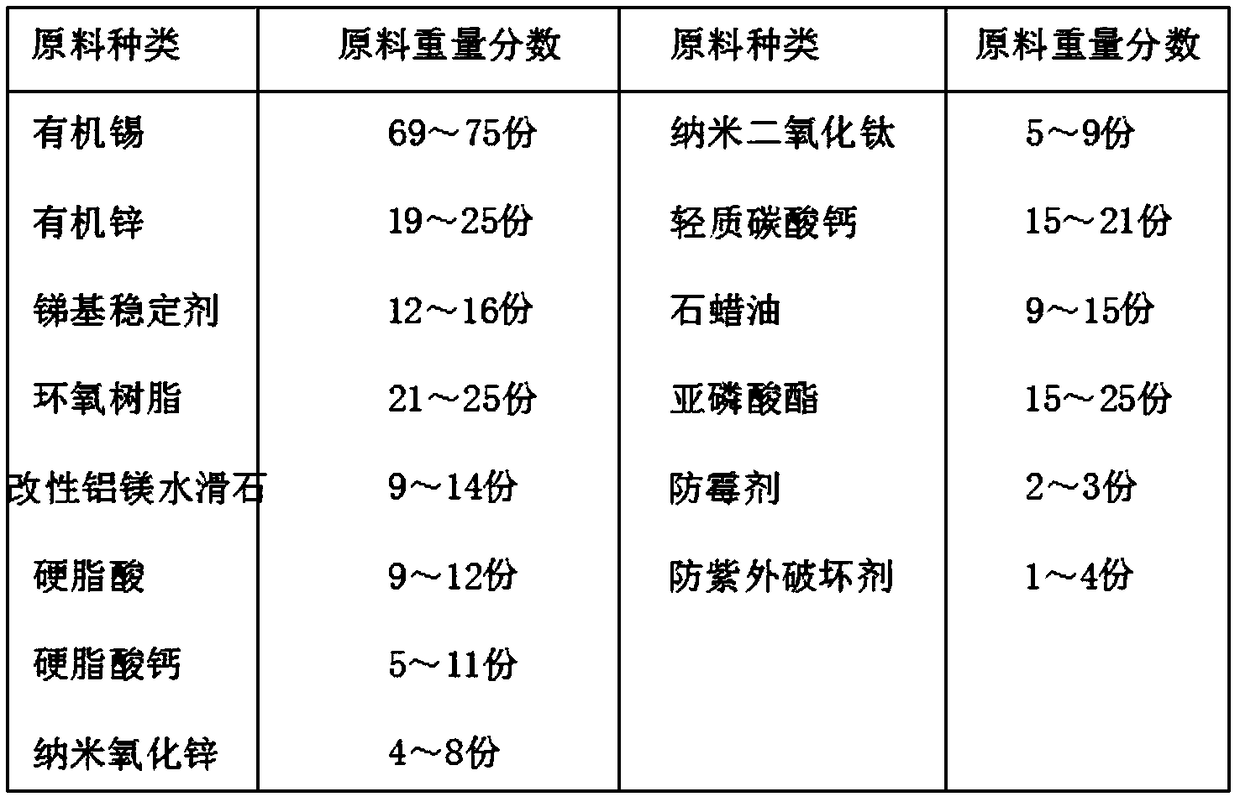

[0019] see figure 1 As shown, the technical solution adopted in the present invention is: an environment-friendly PVC profile organotin stabilizer, which includes the following raw materials: 75 parts of organotin, 25 parts of organozinc, 16 parts of antimony-based stabilizer 25 parts of epoxy resin, 14 parts of modified aluminum-magnesium hydrotalcite, 12 parts of stearic acid, 11 parts of calcium stearate, 8 parts of nano-zinc oxide, 9 parts of nano-titanium dioxide, 21 parts of light calcium carbonate, paraffin oil 15 parts and 25 parts phosphite.

[0020] Wherein, the environment-friendly PVC profile organotin stabilizer is also added with 3 parts of antifungal agent.

[0021] Wherein, the environment-friendly PVC profile organotin stabilizer is also added with 4 parts of anti-ultraviolet damage agent.

[0022] Wherein, the anti-ultraviolet damage agent includes γ-FeO(OH), ZnCO 3 and FeTiO 3 -MgTiO 3 , among which, γ-FeO(OH), ZnCO 3 and FeTiO 3 -MgTiO 3 The additio...

Embodiment 2

[0024] see figure 1 As shown, the technical solution adopted in the present invention is: an environment-friendly PVC profile organotin stabilizer, which includes the following raw materials: 69 parts of organotin, 19 parts of organozinc, 12 parts of antimony-based stabilizer 21 parts of epoxy resin, 9 parts of modified aluminum-magnesium hydrotalcite, 9 parts of stearic acid, 5 parts of calcium stearate, 4 parts of nano-zinc oxide, 5 parts of nano-titanium dioxide, 15 parts of light calcium carbonate, paraffin oil 9 parts and phosphite 15 parts.

[0025] Wherein, the environment-friendly PVC profile organotin stabilizer is also added with 2 parts of antifungal agent.

[0026] Wherein, the environment-friendly PVC profile organotin stabilizer is also added with 1 part of anti-ultraviolet damage agent.

[0027] Wherein, the anti-ultraviolet damage agent includes γ-FeO(OH), ZnCO 3 and FeTiO 3 -MgTiO 3 , among which, γ-FeO(OH), ZnCO 3 and FeTiO 3 -MgTiO 3 The addition rat...

Embodiment 3

[0029] see figure 1 As shown, the technical solution adopted in the present invention is: an environment-friendly PVC profile organotin stabilizer, which includes the following raw materials: 75 parts of organotin, 19 parts of organozinc, 16 parts of antimony-based stabilizer 21 parts of epoxy resin, 14 parts of modified aluminum-magnesium hydrotalcite, 9 parts of stearic acid, 11 parts of calcium stearate, 4 parts of nano-zinc oxide, 9 parts of nano-titanium dioxide, 15 parts of light calcium carbonate, paraffin oil 15 parts and phosphite 15 parts.

[0030] Wherein, the environment-friendly PVC profile organotin stabilizer is also added with 3 parts of antifungal agent.

[0031] Wherein, the environment-friendly PVC profile organotin stabilizer is also added with 1 part of anti-ultraviolet damage agent.

[0032] Wherein, the anti-ultraviolet damage agent includes γ-FeO(OH), ZnCO 3 and FeTiO 3 -MgTiO 3 , among which, γ-FeO(OH), ZnCO 3 and FeTiO 3 -MgTiO 3 The addition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com