Manufacture method of PVC (Poly Vinyl Chloride) product

A product manufacturing and heat stabilizer technology, applied in the field of polyvinyl chloride (PVC) product manufacturing, can solve the problems of increasing the toxicity of PVC products, increasing the cost of PVC products, etc., and achieve the effect of benefiting the health and increasing the heat stabilization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

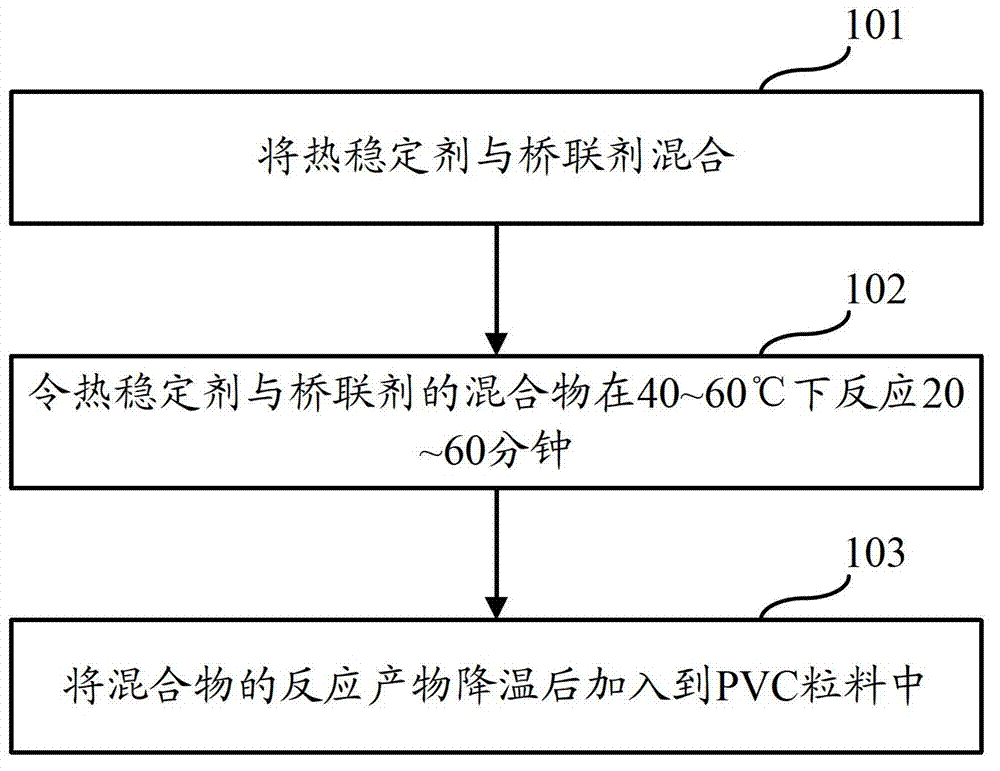

[0045] Such as figure 1 As shown, the steps of adding a bridging agent to the heat stabilizer that needs to be added to the PVC pellets include:

[0046] Step 101, mixing heat stabilizer and bridging agent;

[0047] Which one of the heat stabilizer and bridging agent to use specifically can be determined according to actual needs.

[0048] Step 102, reacting the mixture of heat stabilizer and bridging agent at 40-60°C for 20-60 minutes;

[0049]React at 40-60°C for 20-60 minutes to fully combine the molecules of the thermal stabilizer and the bridging agent.

[0050] In step 103, the temperature of the reaction product of the mixture is lowered to below 40° C. and then added to the PVC pellets.

[0051] The temperature of the reaction product of the heat stabilizer and the bridging agent mixture is lowered to below 40° C., and added to the PVC pellets according to the existing method.

[0052] After that, processes such as molding of PVC products can be carried out to obta...

Embodiment 2

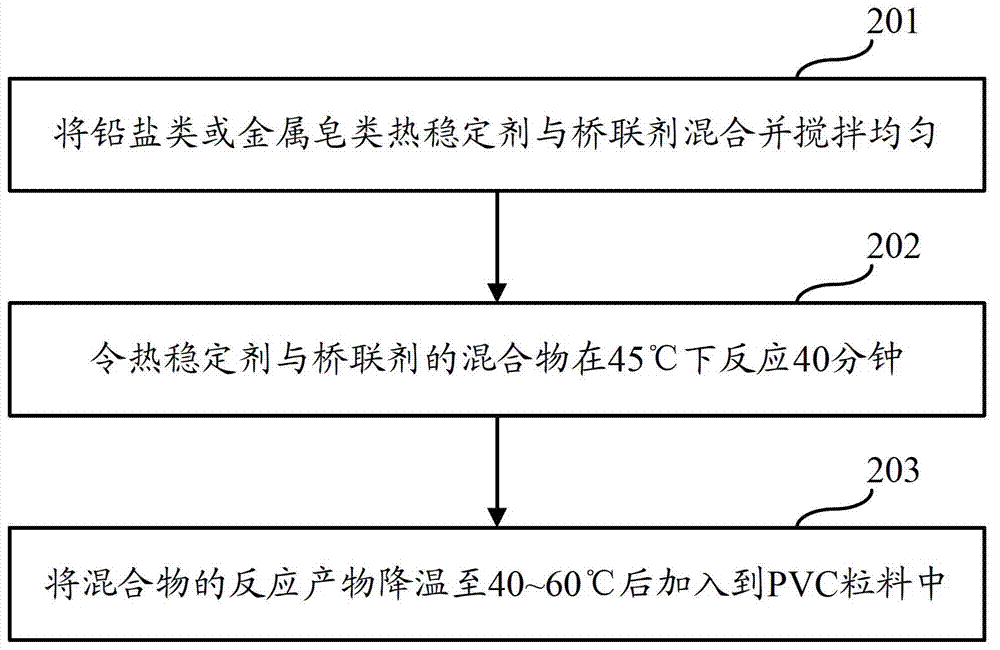

[0054] Such as figure 2 As shown, the steps of adding a bridging agent to the heat stabilizer that needs to be added to the PVC pellets include:

[0055] Step 201, mixing the lead salt or metal soap heat stabilizer with the bridging agent and stirring evenly;

[0056] By stirring, the heat stabilizer and the bridging agent can be mixed more fully, wherein the bridging agent can use sodium dodecylbenzenesulfonate, sodium fatty alcohol polyoxyethylene ether sulfate, fatty alcohol polyoxyethylene ether ammonium sulfate, Any one of the five types of sodium lauryl sulfate and nonylphenol ethoxylates.

[0057] Wherein, the addition amount of bridging agent can be 2%~5% of heat stabilizer weight, is preferably 3%.

[0058] Step 202, allowing the mixture of thermal stabilizer and bridging agent to react at 45° C. for 40 minutes.

[0059] In step 203, the temperature of the reaction product of the mixture is lowered to below 40° C. and then added to the PVC pellets.

Embodiment 3

[0061] Add 1.1kg of sodium dodecylbenzenesulfonate (bridging agent) to 50kg of lead salt PVC heat stabilizer for pipes, and stir evenly; raise the temperature to 45°C, and control the temperature range between 43 and 47°C; Stir and react in this temperature range for 40 minutes; then cool down to below 40°C and discharge. The above reaction product is added into PVC pellets, stirred to obtain PVC products.

[0062] After being treated by the method of the present invention, the thermal stability time of PVC products can be increased by 10-30% under the same amount of heat stabilizer added. In the case of the same thermal stability time, the amount of thermal stabilizer added can be reduced by 10% to 30%.

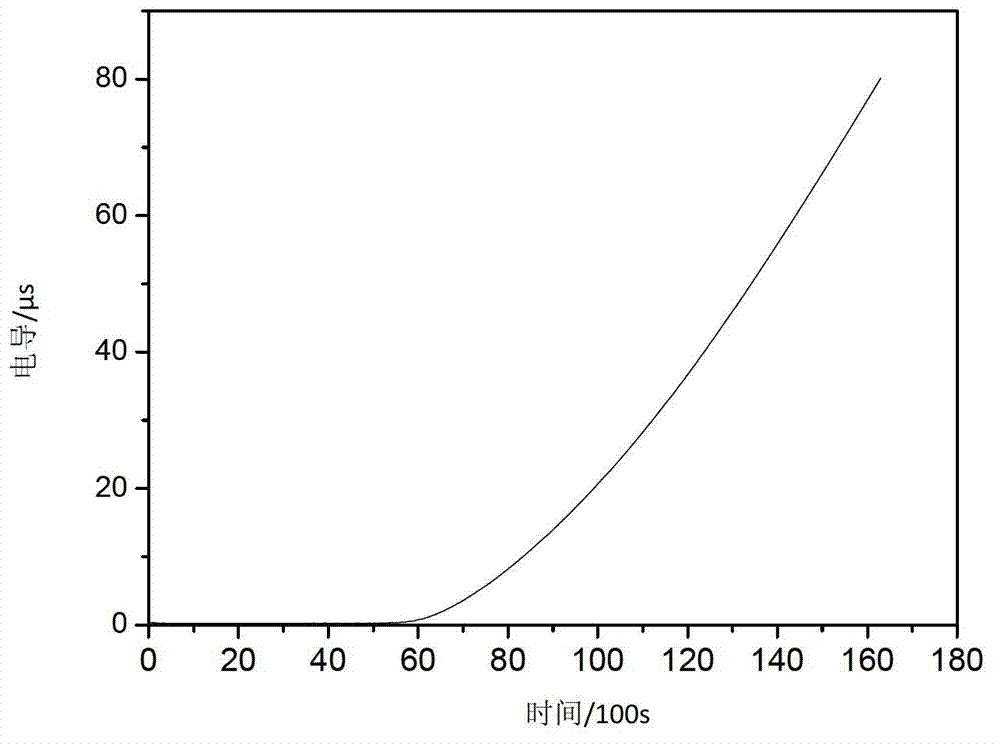

[0063] For verifying effect of the present invention, carried out comparative experiment, wherein image 3 It is the de-HCl curve of the PVC pipe obtained by using the traditional heat stabilizer addition method. The heat stabilizer is a lead salt PVC heat stabilizer for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com