Polishing slag modified flame-retardant PVC plasticizing paste and preparation method thereof

A technique of polishing slag and plastisol, which is applied in the direction of adding flame-retardant fibers, special paper, and fireproofing agents, can solve the problems of reduced flame-retardant performance and chlorine content, and achieves improved flame-retardant properties, reduced production costs, and better The effect of flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention provides a flame-retardant PVC plasticizer modified by polishing slag and a preparation method thereof. In order to make the object, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0026] Implementation example 1 Preparation of flame retardant conveyor belt:

[0027] 1. Mixture:

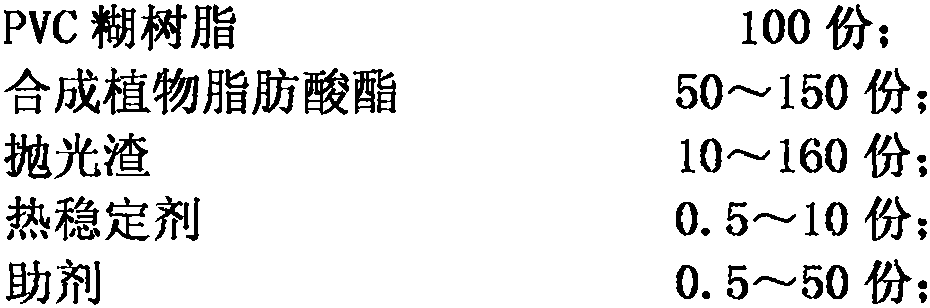

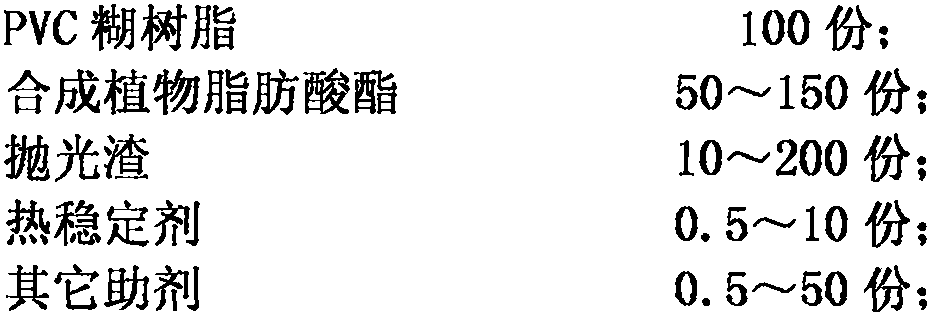

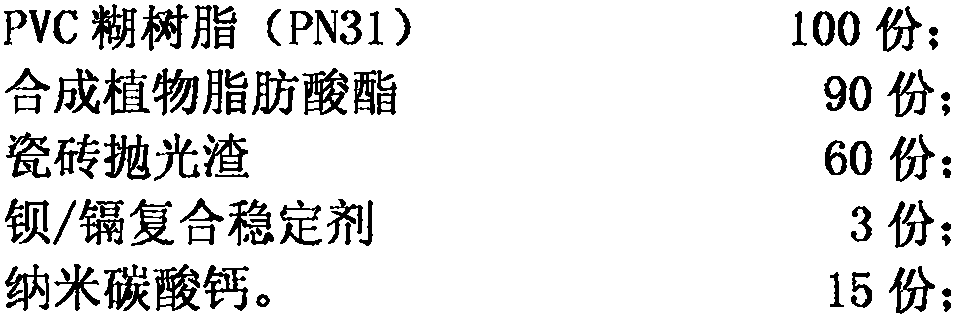

[0028] A weighs the raw materials in the following formula (band core paste) by mass parts, for subsequent use:

[0029]

[0030] Put the above-mentioned raw materials prepared except synthetic vegetable fatty acid esters into a high-speed mixer, stir for 5 minutes, discharge into a low-speed cold mixer and stir for 10 minutes, and discharge the materials after cooling to obtain a flame-retardant conveyor belt Core batter mix....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com