A kind of preparation method of flame retardant fabric

A flame-retardant fabric, polyester flame-retardant technology, applied in the field of fabrics, can solve the problems affecting material processing, mechanical and application performance, compatibility and interface, poor compatibility of polymers, etc., to achieve the suppression of thermal decomposition process , reduce thermal decomposition rate, strong flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052]A method for preparing a flame-retardant fabric specifically includes the following steps:

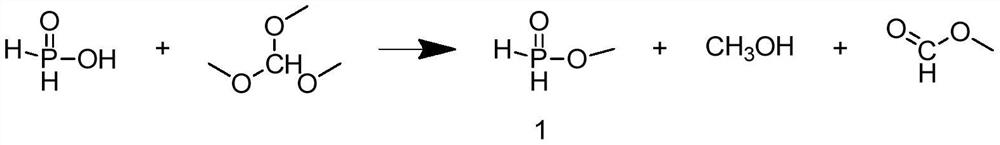

[0053]S1, synthesis of methyl hypophosphite

[0054]The reaction formula is as follows:

[0055]

[0056]The solvent in the commercially available 50% hypophosphorous acid was removed by rotary evaporation to obtain 95% hypophosphorous acid. In an ice-water bath, 200 mol 95% hypophosphorous acid and 240 mol trimethyl formate were added to the reactor, stirred for 10 minutes, and then heated When the temperature is 35°C, continue to stir and react for 3 hours, and distill off methanol and methyl formate to obtain methyl hypophosphite 1 as a pale yellow solid powder with a yield of 98.4%;

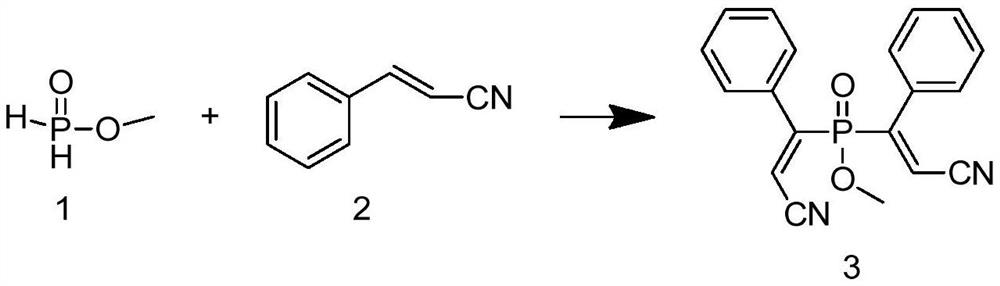

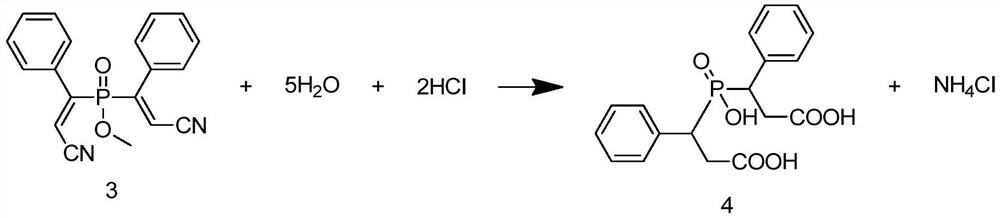

[0057]S2 Synthesis of Methyl Bis(1-phenyl-2-cyanoethyl)phosphonate

[0058]The reaction formula is as follows:

[0059]

[0060]In an ice-water bath, 150 mol of methyl hypophosphite 1, 330 mol of benzene acrylonitrile 2 and 22.5 mol of the catalyst triethylamine were added to the reactor. After stirring for 10 minutes, the t...

Embodiment 2

[0075]A method for preparing a flame-retardant fabric specifically includes the following steps:

[0076]S1, synthesis of methyl hypophosphite

[0077]The reaction formula is as follows:

[0078]

[0079]The solvent in the commercially available 50% hypophosphorous acid was removed by rotary evaporation to obtain 99% hypophosphorous acid. In an ice-water bath, 200 mol 99% hypophosphorous acid and 260 mol trimethyl formate were added to the reactor, and stirred for 15 minutes. The temperature was raised to 40° C., and the reaction was continued for 4 hours. The methanol and methyl formate were distilled off to obtain methyl hypophosphite 1 as a pale yellow solid powder with a yield of 99.2%;

[0080]S2 Synthesis of Methyl Bis(1-phenyl-2-cyanoethyl)phosphonate

[0081]The reaction formula is as follows:

[0082]

[0083]In an ice-water bath, 150 mol of methyl hypophosphite 1, 375 mol of benzene acrylonitrile 2 and 33 mol of catalyst triethylamine were added to the reactor. After stirring for 15 minutes, the ...

Embodiment 3

[0099]A method for preparing a flame-retardant fabric specifically includes the following steps:

[0100]S1, synthesis of methyl hypophosphite

[0101]The reaction formula is as follows:

[0102]

[0103]The solvent in the commercially available 50% hypophosphorous acid was removed by rotary evaporation to obtain 98% hypophosphorous acid. In an ice-water bath, 200 mol 98% hypophosphorous acid and 250 mol trimethyl formate were added to the reactor, stirred for 12 minutes and then heated When the temperature reached 38°C, the reaction was continued to stir for 3 hours, methanol and methyl formate were distilled off, and methyl hypophosphite 1 was obtained as a pale yellow solid powder with a yield of 98.5%;

[0104]S2 Synthesis of Methyl Bis(1-phenyl-2-cyanoethyl)phosphonate

[0105]The reaction formula is as follows:

[0106]

[0107]In an ice-water bath, 150 mol of methyl hypophosphite 1, 360 mol of benzene acrylonitrile 2 and 30 mol of catalyst triethylamine were added to the reactor. After stirring for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com