Patents

Literature

41results about How to "Reduce thermal decomposition rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance environment-friendly aluminum alloy mould release agent

ActiveCN101554642AImprove heat resistanceReduce thermal decomposition rateFoundry mouldsFoundry coresCorrosion inhibitorAluminium alloy

The invention discloses a high-performance environment-friendly aluminum alloy mould release agent which consists of modified organic silicone, grease synthetic ester, anti-rust inhibitor, preservative, surfactant and water. The high-performance environment-friendly aluminum alloy mould release agent adopts the special modified organic silicone and the grease as the composite lubricating mould release agent and is further provided with a variety of the anti-rust inhibitor, the preservative and the surfactant, and the product has excellent heat resistance performance and can greatly improve the high-temperature stability and the high-temperature mould release performance of the product and greatly reduce the occurrence of air holes.

Owner:QIDONG YUSHIRO CHEMICAL INDUSTRY CO LTD +1

Easily collapsed coated sand

ActiveCN101941042AIncrease thermal decomposition rateImprove collapsibilityFoundry mouldsFoundry coresOxideSodium nitrate

The invention discloses easily collapsed coated sand. The sand comprises crude sand, a bonding agent, a curing agent, a collapsing agent and a lubricant, wherein the using amount of the curing agent is 50 to 60 percent of that of the bonding agent; the using amount of the collapsing agent is 30 to 40 percent of that of the bonding agent; the using amount of the bonding agent is 6 to 12 percent ofthe crude sand; the using amount of the lubricant is 2 to 4 percent of the crude sand; the collapsing agent comprises the following components in part by weight: 50 to 60 percent of sodium nitrate, 30 to 40 parts of sodium chloride and 5 to 15 parts of ferric oxide powder; and the bonding agent comprises the following components in part by weight: 60 to 70 parts of phenolic resin, 20 to 30 parts of polyalkylene oxide resin and 5 to 15 parts of poly(ethyl acrylate). The easily collapsed coated sand has the advantages of relatively high thermal disintegration rate, relatively good collapsibility, difficult breaking of a sand core and simple dropping of the sand core.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

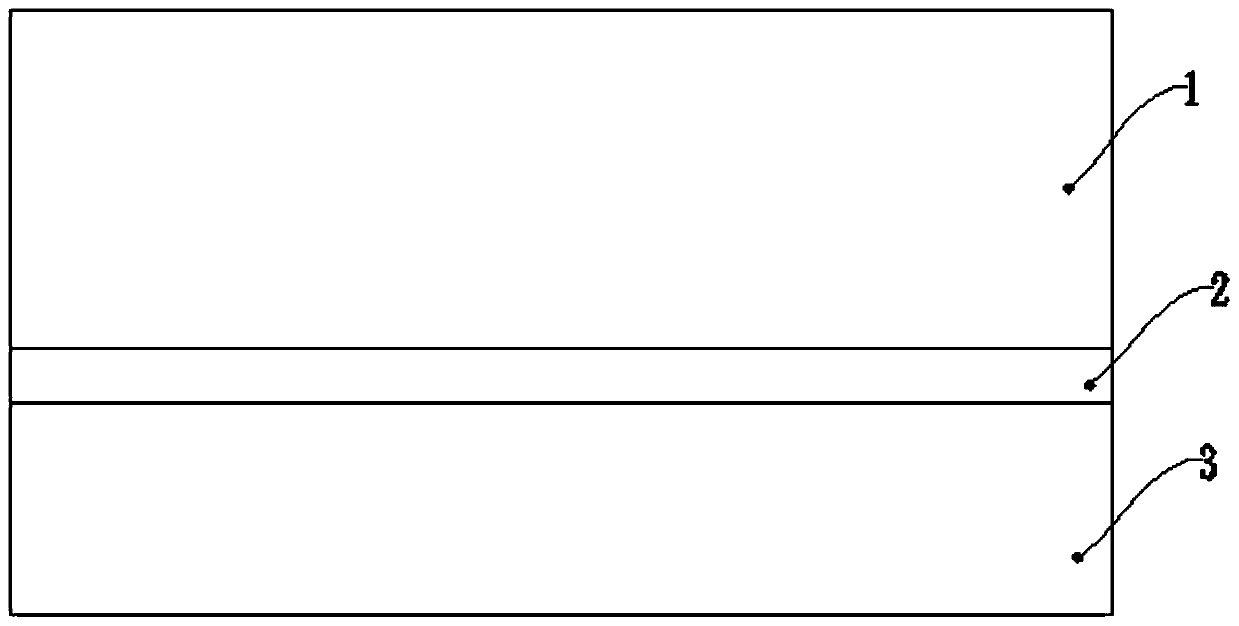

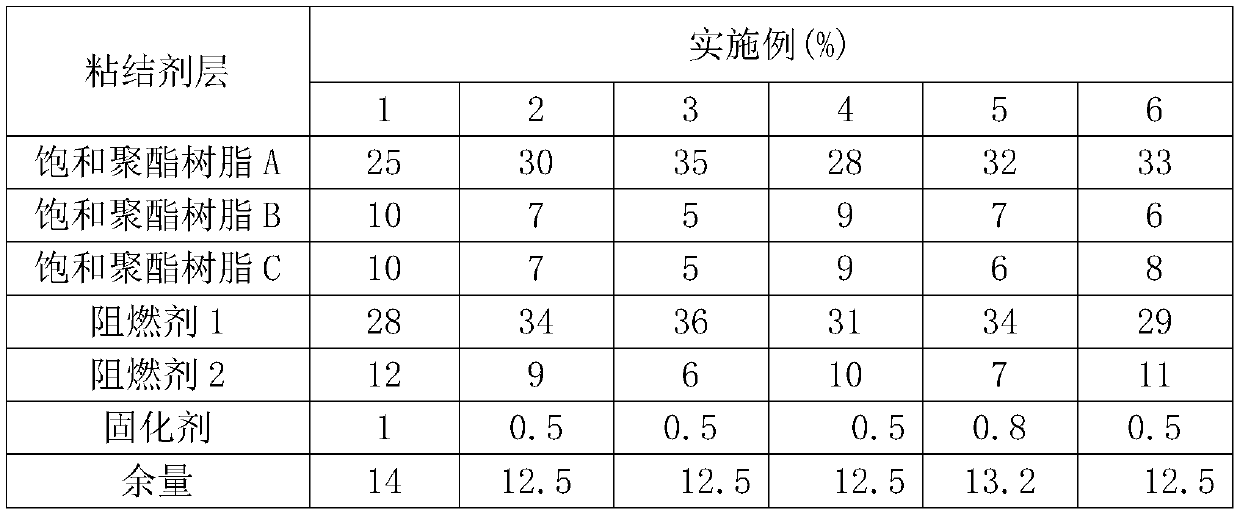

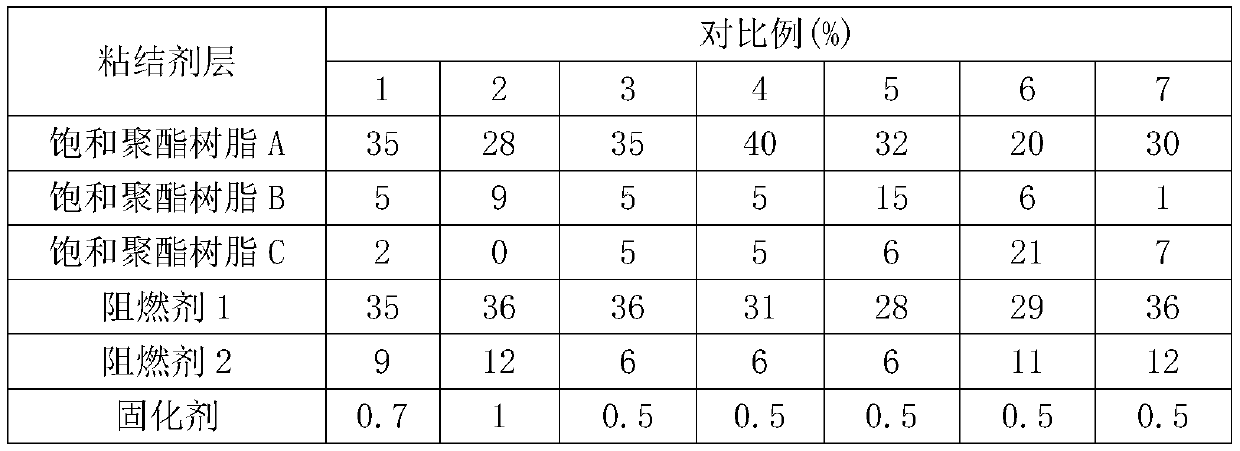

Antimony-free flame-retardant hot-melt adhesive film for FFCs and preparation method thereof

ActiveCN110283562AAchieving Flame RetardancyImprove flame retardant performanceNon-macromolecular adhesive additivesFilm/foil adhesive primer layersPolyester resinFire retardant

The invention discloses an antimony-free flame-retardant hot-melt adhesive film for FFCs and a preparation method thereof. The hot-melt adhesive film comprises a PET insulating layer, a pre-coating layer and an adhesive layer, wherein the pre-coating layer is disposed between the PET insulating layer and the adhesive layer, and the thickness of the adhesive layer is smaller than the thickness of the PET insulating layer; the adhesive layer comprises, by weight percentage, 25-35% of a saturated polyester resin A, 5-10% of a saturated polyester resin B, 5-10% of a saturated polyester resin C, 28-36% of a flame retardant a, 6-12% of a flame retardant b, 0.5-1% of a curing agent and 12.5-14% of a balance material; the saturated polyester resin C is a DOPO phosphorus-containing modified flame-retardant saturated polyester resin, and the flame retardant a and the flame retardant b are both an antimony-free flame retardant. The antimony-free flame retardant is more environmentally friendly and can achieve the flame-retardant effect of VW-1.

Owner:广东莱尔新材料科技股份有限公司

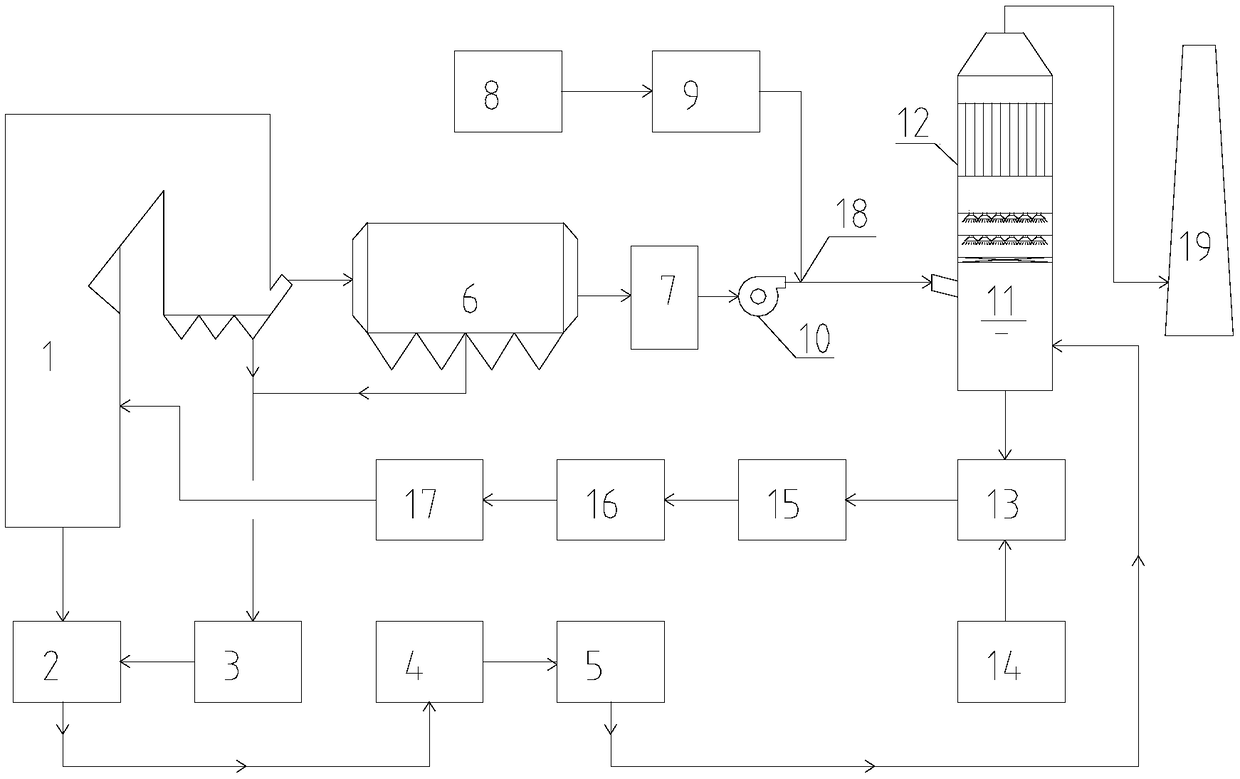

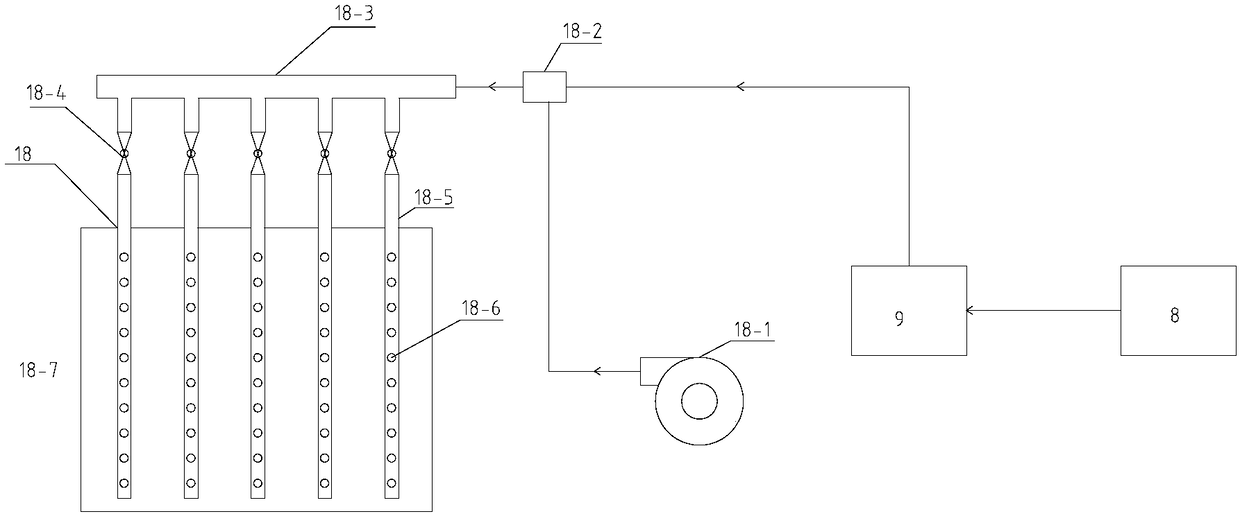

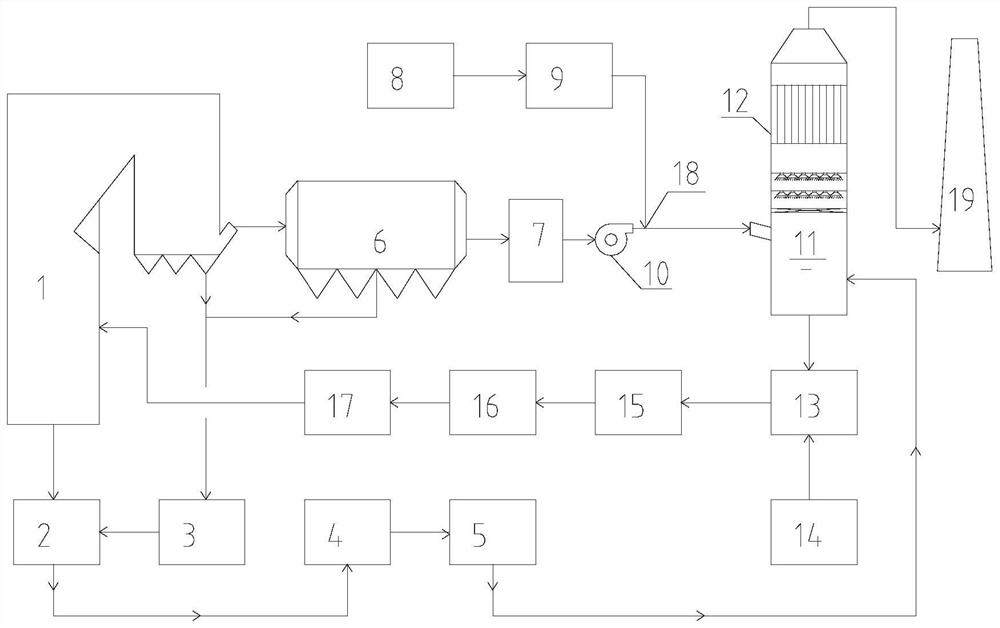

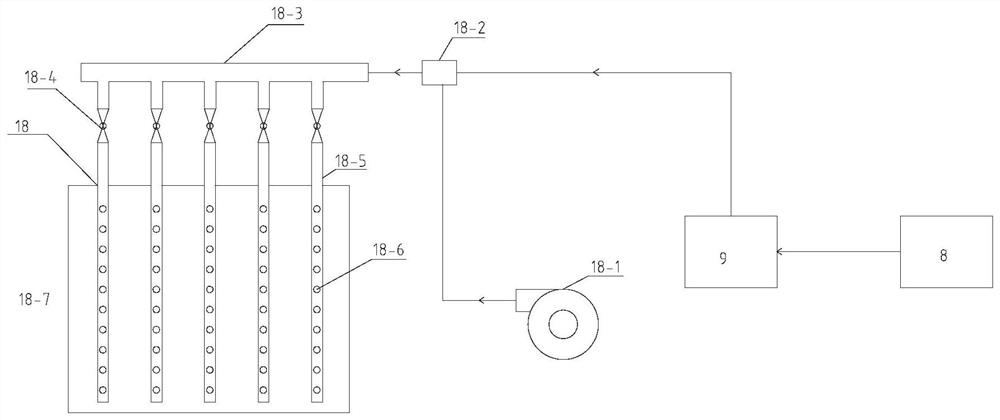

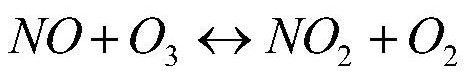

Alkaline furnace flue gas wet process denitration process and device capable of cyclically utilizing absorbent

ActiveCN108380017AMaintain vulcanizationThe recovery rate meetsGas treatmentDispersed particle separationSlurrySodium sulfate

The invention discloses an alkaline furnace flue gas wet process denitration process and device capable of cyclically utilizing an absorbent. The process comprises the following steps that (1) alkaline recovery furnace flue gas is subjected to high-temperature electric dust removal, heat exchange temperature reduction and ozone oxidation, and is then conveyed into a wet process absorption tower; denitration absorption liquid in the absorption tower performs cyclical spraying absorption on flue gas; the purified flue gas is discharged out through a chimney; (2) slurry after the flue gas is subjected to spraying absorption is discharged out of the absorption tower; a denitrification agent is added into the slurry; sodium sulfate slurry after the denitrification treatment is conveyed into a black liquor concentration work procedure of the alkaline recovery furnace; concentrated sodium sulfate and black liquid mixed liquid is sprayed into the alkaline recovery furnace; combustion reductionis performed in the alkaline recovery furnace; a combustion reduction product is discharged and is then dissolved and causticized; denitration absorption liquid is regenerated again. The flue gas wetprocess denitration absorbent can be cyclically utilized; the denitration operation cost is low; the denitration absorbent is not consumed; no ozone escape exists; zero waste water discharging is realized.

Owner:HANGZHOU TIANLAN ENVIRONMENTAL PROTECTION ENG DESIGN

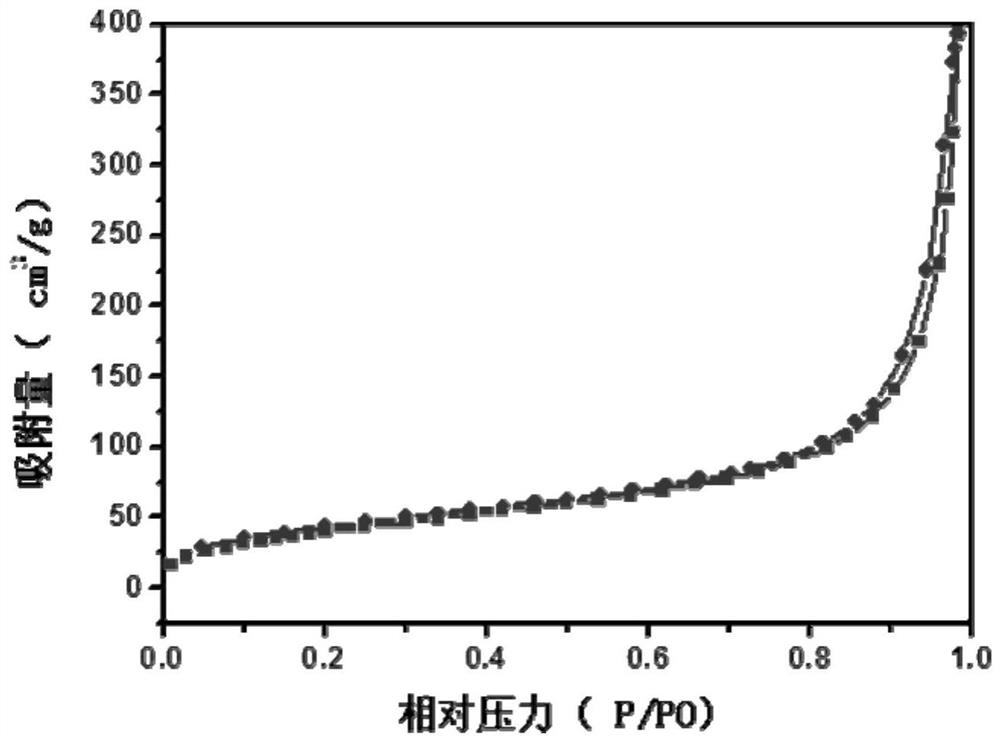

Preparation method of boron-modified phenolic aerogel

PendingCN112175230AHigh compressive strengthLow thermal conductivityHexamethylenetetramineFlight vehicle

The invention relates to a preparation method of a boron-modified phenolic aerogel. The method comprises the following steps of: dissolving linear phenolic resin, tributyl borate and other organic boric acids in an ethanol solution, adding a cross-linking agent hexamethylenetetramine, carrying out an initial low-viscosity sol-gel process to obtain a boron composite phenolic wet gel, and carrying out normal-pressure drying to obtain the boron modified phenolic aerogel. And tributyl borate and other organic boron sources can be uniformly mixed in the solution, so that the viscosity of the systemis unchanged or slowly rises, thereby effectively ensuring the stability of the glue injection process. In addition, boron particles form boron oxide in the ablation application process, and the boron oxide permeates into gaps of the phenolic aerogel to fill the gaps of the phenolic aerogel and melt and coat a phenolic matrix. The prepared boron-modified phenolic aerogel has the advantages of good specific surface area, oxidation resistance, low heat conductivity coefficient and density, good processability and the like, can maintain the original shape and performance at high temperature, andis expected to be applied to the field of external thermal protection of high-speed aircrafts.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

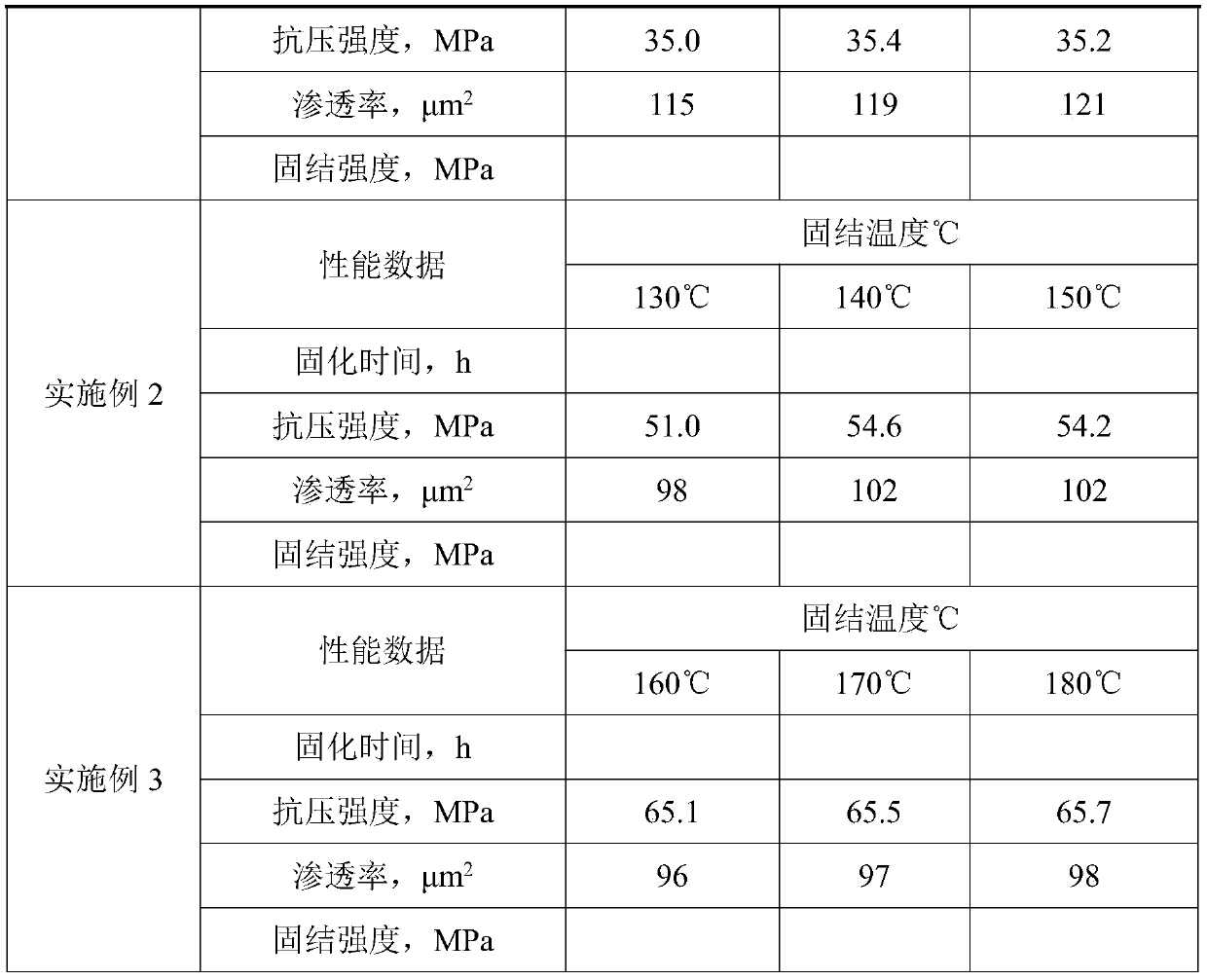

Self-polymerized consolidated pressure-resistant permeation-increasing temperature-resistant sand preventing agent

ActiveCN110684517AImprove thermal stabilityHigh decomposition temperatureDrilling compositionP-nitrobenzoic acidPoly ethylene

The invention discloses a self-polymerized consolidated pressure-resistant permeation-increasing temperature-resistant sand preventing agent. The self-polymerized consolidated pressure-resistant permeation-increasing temperature-resistant sand preventing agent comprises the following components, in percentage by mass: 30-40% of a resin compounding system; 40-50% of an organic solvent; 5-7% of a coupling agent; 5-8% of a filler; 4 to 5% of a curing agent, and 5 to 8% of an emulsifier; wherein the sum of the mass percentages of the components is 100%; the curing agent is p-nitrobenzoic anhydrideand tetrachlorophthalic anhydride which are mixed in equal mass; the filler is high-temperature-resistant multi-mineral fine powder and phenolic fiber; and the high-temperature-resistant multi-mineral fine powder is a mixture of magnesium oxide, aluminum oxide and silicon oxide; the resin compounding system is formed by compounding epoxy resin E-44, epoxy resin E-51, phenolic resin F-51 and polyvinylpyrrolidone K30. The sand preventing agent is mainly used for chemical sand control of high-temperature and high-pressure wells, can be injected into stratums without moving tubular columns, andachieve the purposes of sand control and sand consolidation.

Owner:SICHUAN JIEBEITONG ENERGY TECH CO LTD

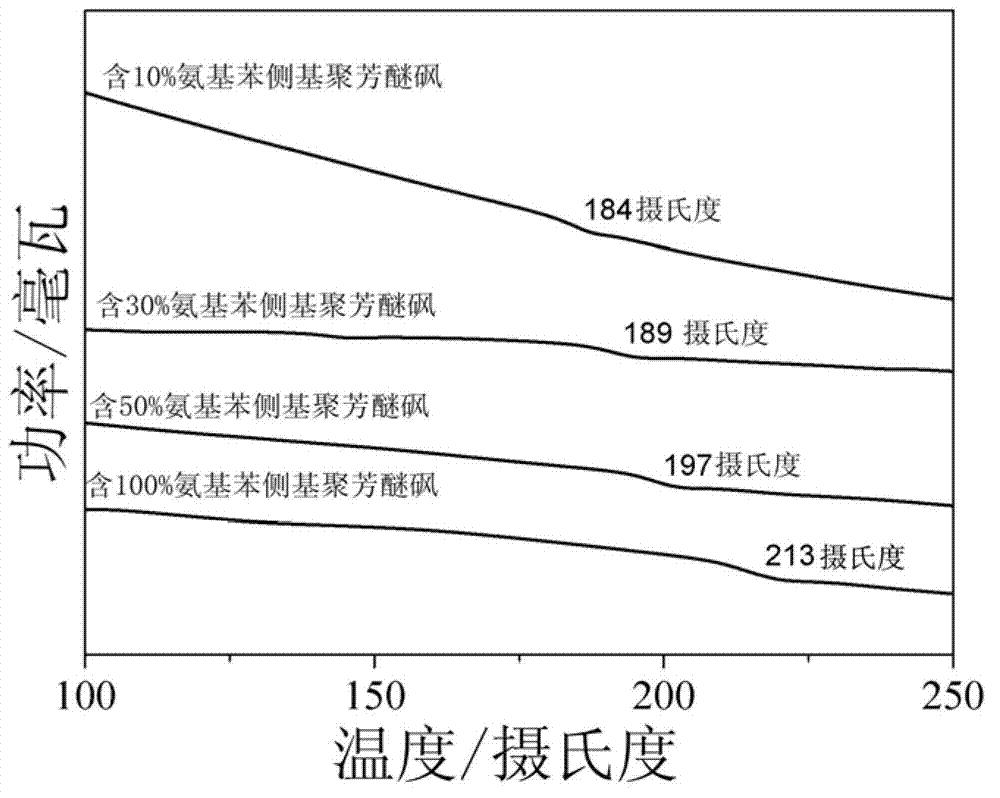

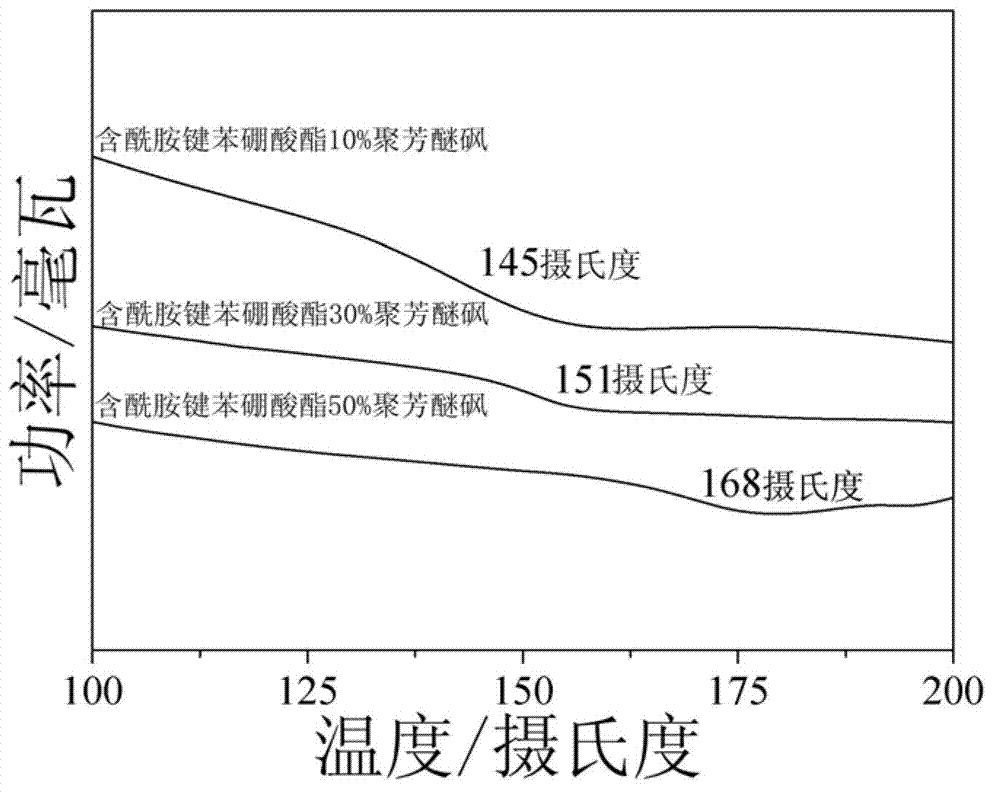

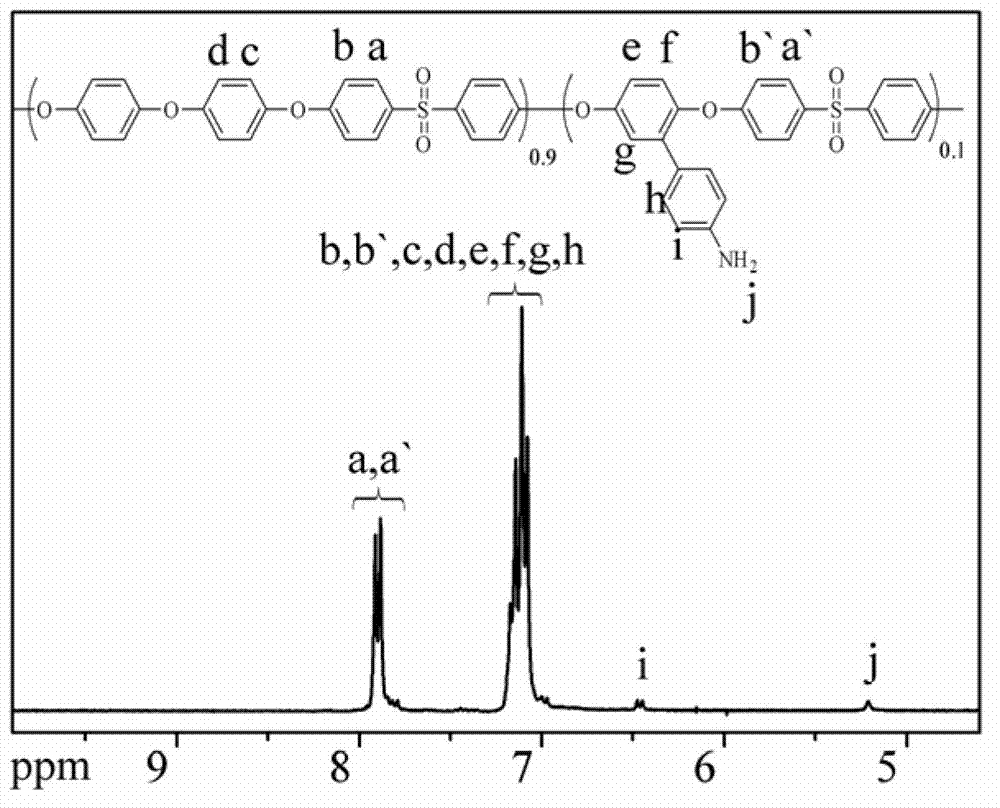

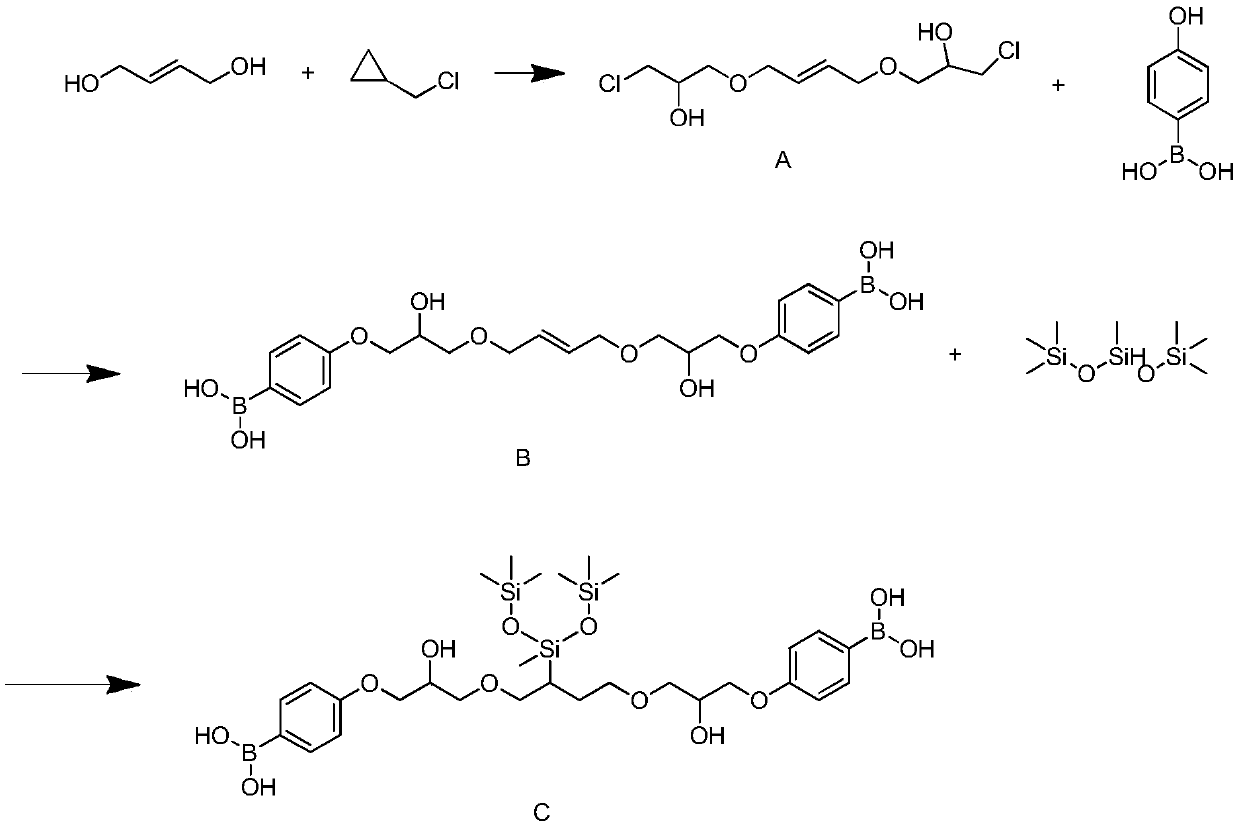

Amido bond phenylboronic acid ester-containing polyether sulphone polymer and preparation method thereof

InactiveCN103242530AExcellent high temperature ablation resistanceReduce thermal decomposition rateOrganic compound preparationGroup 3/13 element organic compoundsOrganic synthesisSide chain

The invention relates to an amido bond phenylboronic acid ester-containing polyether sulphone polymer and a preparation method thereof, belonging to the technical field of macromolecular materials. The amido bond-containing phenylboronic acid ester polyether sulphone polymer is of a polymer with a polyether sulphone main chain and an amido bond phenylboronic acid ester-containing side chain. The preparation method comprises the steps of: firstly, synthesizing amino-benzene side group-containing polyether sulphone, then performing an amidation reaction on the amino-benzene side group-containing polyether sulphone and carboxyl phenylboronic acid pinacol ester, and carrying out acetone treatment to obtain the amido bond phenylboronic acid ester-containing polyether sulphone material. The phenylboronic acid ester can be quantitatively introduced into the polyether sulphone main chain by adopting an amidation method, thus having potential applications to aspects of catalysis, inorganic material blend polymer composites, flame retardance and the like; in addition, the phenylboronic acid ester is an important reaction intermediate in organic synthesis, and therefore, the amido bond phenylboronic acid ester-containing polyether sulphone is an important reaction intermediate in functionalized polymer synthesis, thus having potential applications on the aspects of preparing luminescent materials, sensing materials and the like.

Owner:JILIN UNIV

Manufacturing process for jewelry protective film

ActiveCN110373057AImprove adhesionImprove wear resistanceFireproof paintsPolyurea/polyurethane coatingsTectorial membranePolyethylene glycol

The invention discloses a manufacturing process for a jewelry protective film. The manufacturing process is composed of the following raw materials in parts by weight: 100 parts of modified polyurethane, 5 to 10 parts polyethylene glycol and 100 parts of isopropanol. The manufacturing process comprises the following concrete steps: heating prepared modified polyurethane and polyethylene glycol to80 to 85 DEG C for melting, carrying out mixing under stirring for 30 min, then slowly adding the isopropanol, carrying out cooling to 35 to 40 DEG C under stirring so as to obtain a jewelry protective liquid, uniformly spraying the jewelry protective liquid onto the surface of jewelry at a same temperature, and carrying out natural drying for 1 to 2 h so as to obtain the jewellery protective film. According to the invention, the polyurethane has strong adhesiveness; a coating film has excellent performances like wear resistance, water resistance and chemical resistance and has poor flame-retardant performance; the modified polyurethane prepared by using the method provided by the invention has excellent water resistance and high-temperature flame retardancy; thus, the jewelry protective film prepared by using the manufacturing process provided by the invention is greatly improved in high-temperature stability and oxidation resistance.

Owner:东莞市熙宝福五金科技有限公司

Antiflaming polylactic acid composite material prepared by RDP (resorcinol diphenyl phosphate) coated nano attapulgite

InactiveCN104045985AImprove flame retardant performanceImprove mechanical propertiesDiphenyl phosphateCarbon layer

The invention discloses an antiflaming polylactic acid composite material prepared by RDP (resorcinol diphenyl phosphate) coated nano attapulgite. The RDP coated nano attapulgite is prepared from RDP and nano attapulgite which are taken as raw materials under an ultrasonic condition. The antiflaming polylactic acid composite material is prepared by virtue of the following steps: mixing the polylactic acid and RDP coated nano attapulgite at a mass ratio of (60-95):(40-5) at a high speed, extruding by use of an extruder, cooling and prilling. The antiflaming polylactic acid composite material has a simple formula, is remarkably improved in mechanical property, has good antiflaming efficiency and good heat stability, can form a stable and compact carbon layer in burning, has no molten drops, and generates less smoke.

Owner:NANJING UNIV OF SCI & TECH

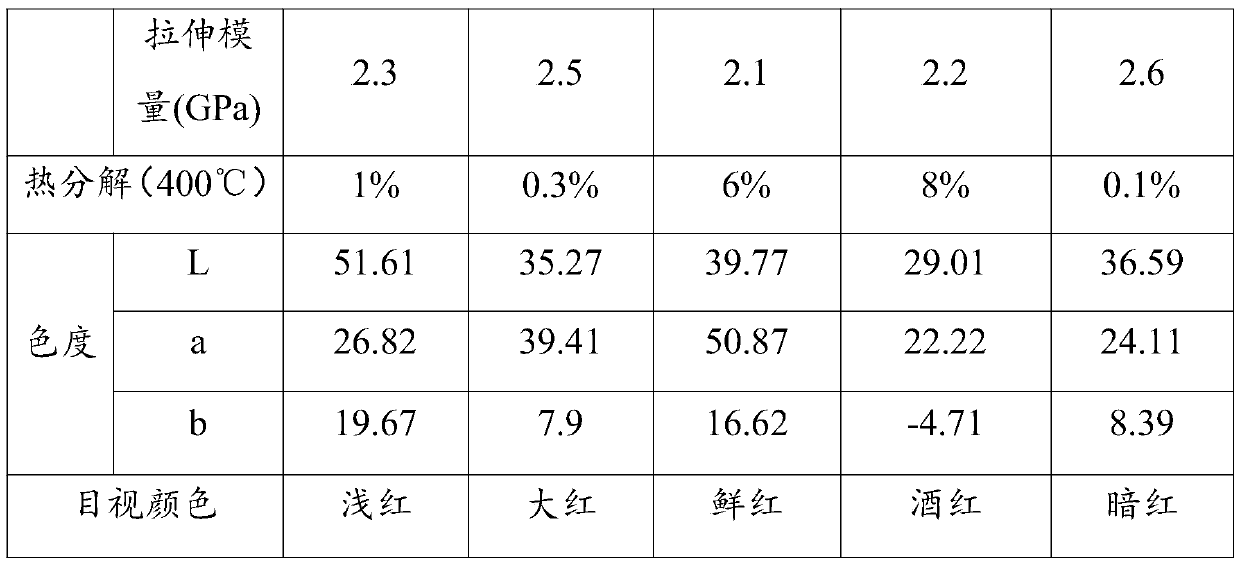

Preparation method of high-temperature-resistant red polyimide film

PendingCN110724287ASolve the temperature differenceReduce thermal decomposition ratePolymer sciencePolyamide

The invention discloses a preparation method of a high-temperature-resistant red polyimide film. The method comprises the following steps: 1) mixing a heat stabilizer, a coupling agent, a solvent andan organic red pigment, and carrying out ultrasonic stirring treatment to obtain a modified red solution; 2) adding an aromatic diamine into a solvent for dissolving; 3) mixing the modified red solution prepared in step 1) with the dissolved solution prepared in step 2), and performing dispersing by using a high-speed emulsifying pump; 4) adding aromatic dianhydride into an emulsified solution obtained in step 3) in batches, and performing a reaction to obtain a polyamide acid composite solution; and 5) performing slobbering forming on the polyamide acid composite solution obtained in step 4)to obtain the high-temperature-resistant red polyimide film. The organic pigment is modified with the coupling agent and the heat stabilizer in the solvent before being used, so that the problem of temperature difference resistance of the organic red pigment is solved, and meanwhile, and the coloring effect of the film is guaranteed.

Owner:WUXI SHUNXUAN NEW MATERIALS +2

Anti-static cable sheath material and preparation method thereof

The invention discloses an anti-static cable sheath material. The anti-static cable sheath material is composed of, by weight, 2-4 parts of erucyl amide, 570-600 parts of polyvinyl chloride, 17-20 parts of fulvic acid, 0.06-0.1 part of sodium iodide, 40-50 parts of isopropyl alcohol, 70-100 parts of saponite, 2-3 parts of sp80, 20-30 parts of lactide, 0.2-0.25 part of L-arginine, 4-6 parts of polyving akohol, 1.6-2 parts of salicylanilide, 3-5 parts of sodium potassium silicate, 2-4 parts of 3-phenoxy-1-propanol, 10-18 parts of cresyl diphenyl phosphate and 2-4 parts of calcium palmitate. According to the cable sheath material, the components such as the erucyl amide and the salicylanilide are added, good anti-static property is achieved, the anti-static cable sheath material is suitable for protection of wires of electronic products such as household appliances and instruments, and the safety is high.

Owner:HEFEISHI SHENZHAO ELECTRONICS

Low-shrinkage composite PE laminating material and preparation method thereof

InactiveCN111205542AHigh tensile strengthHigh thermal stability and barrier propertiesPolyacrylamideAnoxomer

The invention provides a low-shrinkage composite PE laminating material and a preparation method thereof, and relates to the technical field, and the low-shrinkage composite PE laminating material isprepared from the following raw materials: low density polyethylene, modified polylactic acid, poly(1, 2-propylene glycol adipate), modified nano cellulose, polyacrylamide and an antioxidant. The low-shrinkage composite PE laminating material disclosed by the invention has relatively high tensile strength, elongation at break and tearing strength. Compared with the prior art, the non-toxic biomassdegradable material has high heat stability and barrier property, has a wide application prospect, repeatedly screens the dosage of each raw material, enables the raw materials to be suitable for melt strength and melt flowability required by casting film formation, and also improves the adhesiveness of a coating film and substrate paper. The raw materials have the advantages of the high boilingpoint, low volatility, good environmental sanitation, high viscosity, no toxicity and biodegradability.

Owner:厦门维豪环保科技股份有限公司

Flame retardance heat aging resistant PVC (polyvinyl chloride) foaming trough plate

InactiveCN109517291AGood oil resistanceImprove heat aging resistancePolyvinyl chlorideChlorinated paraffins

The invention discloses a flame retardance heat aging resistant PVC (polyvinyl chloride) foaming trough plate. The flame retardance heat aging resistant PVC foaming trough plate comprises the following raw materials in parts by weight: 60-70 parts of polyvinyl chloride, 10-28 parts of nitrile rubber, 5-13 parts of chlorinated polyethylene rubber, 4-9 parts of a thermoplastic polyurethane elastomer, 5-11 parts of polyamic acid, 2-8 parts of alpha-zirconium phosphate, 5-8 parts of attapulgite, 2-7 parts of muscovite, 3-9 parts of bamboo powder, 8-17 parts of composite foaming agent, 4-11 parts of flame retardant, 0.3-1 part of an aluminum-titanium composite coupling agent, 0.3-1.2 parts of dicumyl peroxide, 0.2-1.3 parts of sulfur, 1.7 parts of an accelerant, 15-30 parts of dioctyl phthalate, 2-9 parts of chlorinated paraffin, 1-3 parts of phenyl phosphorus dichloride, 3-5 parts of resorcinol, and 2-3 parts of a composite heat stabilizer. The flame retardance heat aging resistant PVC foaming trough plate provided by the invention has good heat aging resistance, excellent flame retardance and long service life.

Owner:安徽优丽普科技有限公司

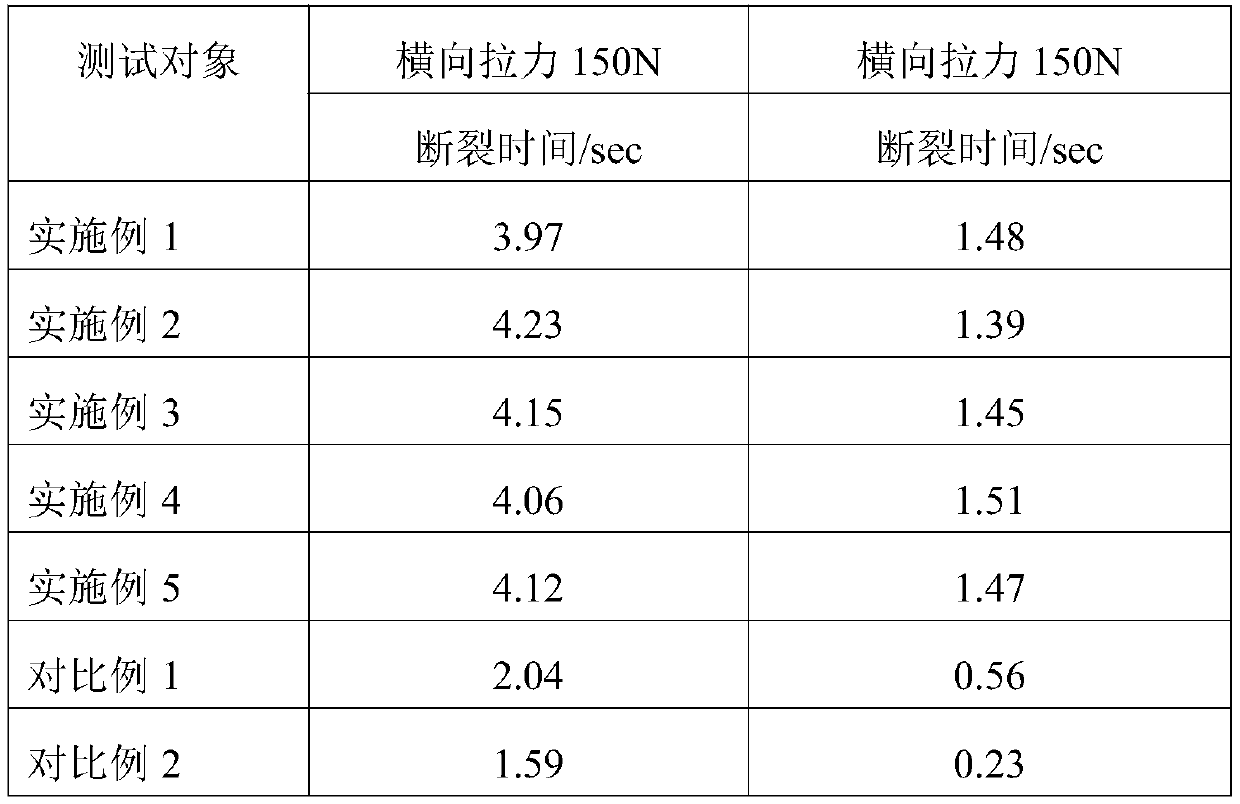

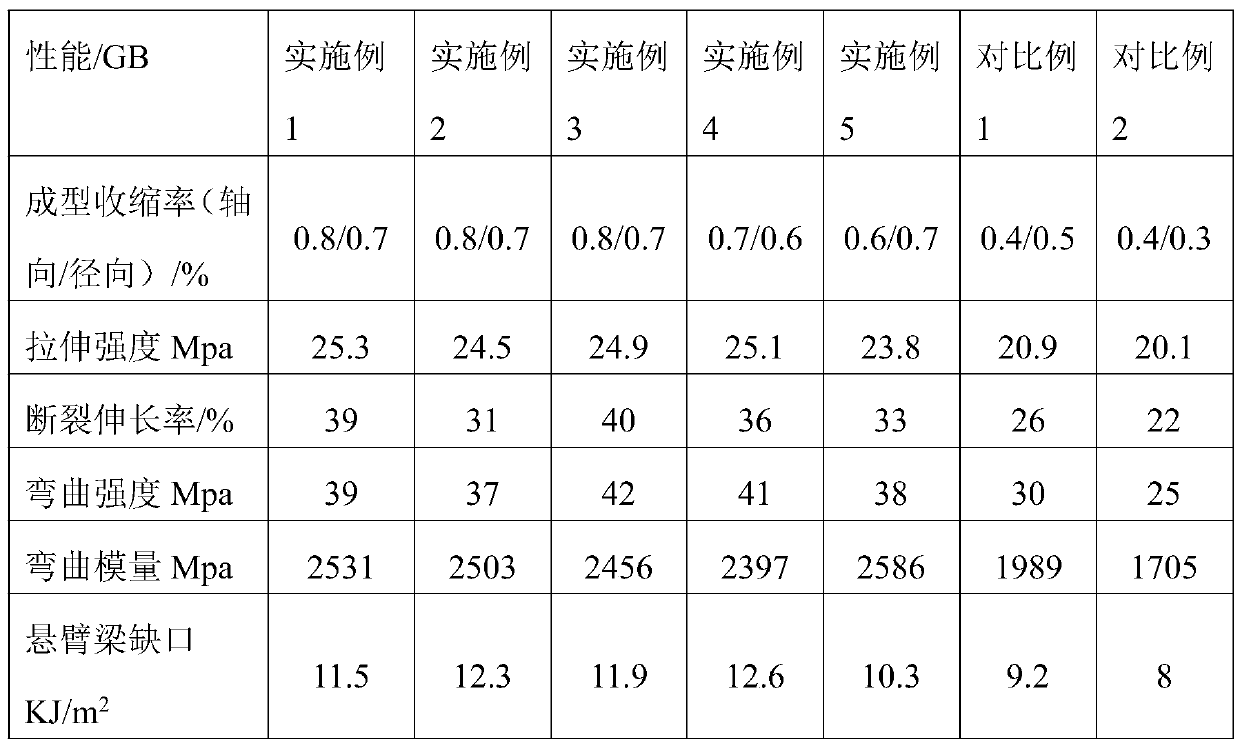

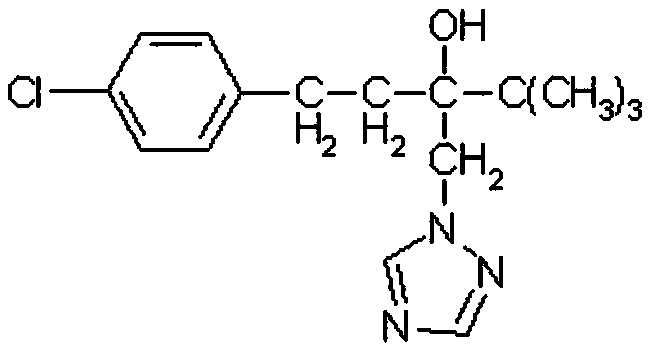

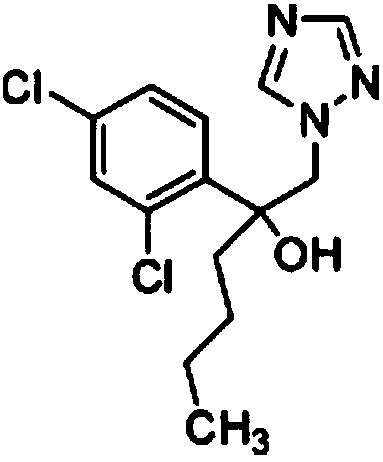

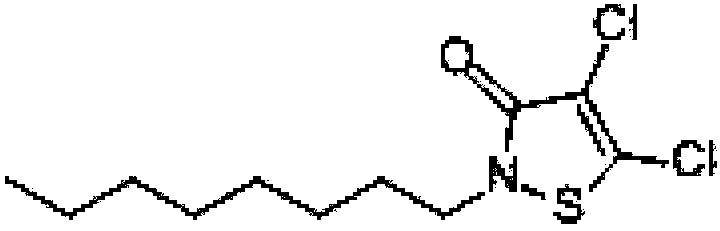

Microcapsule mildew-proof additive, composite material and electric-control element housing

ActiveCN109265748AAvoid direct contactReduce thermal decomposition rateMolecular materialsLinear alkylbenzene

The invention belongs to the technical field of high-molecular material modification, and provides a microcapsule mildew-proof additive, a composite material and an electric-control element housing. The microcapsule mildew-proof additive is prepared from the following components: a core and a coating layer, wherein the core is an organic mildew-proof agent which comprises a triazole bactericide; at least one coating layer coats outside the core; and the coating layer at the outermost layer is direct-chain alkylbenzene. The microcapsule mildew-proof additive mainly solves the three technical problems: necessary adding amount of the mildew-proof agent is too great; the mildew-proof agent has relatively poor dispersion in a plastic product; and in an injection moulding process, the mildew-proof agent is easily decomposed after being over-heated. The microcapsule mildew-proof additive has the main beneficial effects that the adding amount of the mildew-proof agent is small, the sterilizingeffect is good, sterilizing lasting time is long, and humidity of the using environment is higher.

Owner:BENSONG ENG PLASTICS HANGZHOU

Light cold-resistant cable sheathing material and preparation method thereof

InactiveCN105086220AImprove barrier propertiesProtectivePlastic/resin/waxes insulatorsInsulated cablesArginineLactide

The invention discloses a light cold-resistant cable sheathing material. The light cold-resistant cable sheathing material comprises, by weight, 3-4 parts of ethylene glycol, 17-20 parts of light calcium carbonate, 570-600 parts of polyvinyl chloride, 17-20 parts of fulvic acid, 0.06-0.1 part of sodium iodide, 40-50 parts of isopropanol, 70-100 parts of soapstone, 2-3 parts of sp802, 20-30 parts of lactide, 0.2-0.25 part of L-arginine, 2-3 parts of calcium chloride, 1-2 parts of coco fatty acid diethanol amide, 6-10 parts of coal ash, 6-10 parts of diethylene glycol dibenzoate, 1-2 parts of aminopropyltriethoxysilane and 3-4 parts of methyl methacrylate isooctyl. The cable sheathing material is light in weight, convenient to transport, good in toughness and machinability, convenient to install, environmentally friendly, free of toxins and particularly suitable for low-temperature cold regions.

Owner:HEFEISHI SHENZHAO ELECTRONICS

Silicon rubber composite cable material and preparation method thereof

InactiveCN108659538AImprove heat resistanceImprove aging resistancePlastic/resin/waxes insulatorsCarbon fibersCarbon nanotube

The invention discloses a silicon rubber composite cable material and a preparation method thereof. The cable material comprises silicon rubber, ethylene propylene rubber, butadiene rubber, polyarylacetylene resin, stearic acid, zinc oxide, sulfur, 2, 4-dichlorobenzoyl peroxide, coupling agents, graphite, accelerants, anti-aging agents, modified fire retardants, 1, 4-cyclohexanedimethanol diglycidyl ether, carbon fibers, white mica and melamine polyphosphate. The modified fire retardants are prepared according to the process including the steps: gelatinizing starch; adding the starch into water; adding nano-sized magnesium oxide, zirconium oxide, iron oxide and carbon nano-tubes; performing ultrasonic treatment, drying, carbonization, crushing and sieving. The preparation method of the silicon rubber composite cable material is simple in process, and the prepared silicon rubber composite cable material is good in heat resistance and aging resistance and excellent in fire resistance.

Owner:李侠

Low-smoke stable cable material and preparing method thereof

InactiveCN105086223ASlow down the rate of thermal decompositionHigh thermal decomposition temperatureChemistryParaffin oils

The invention discloses a low-smoke stable cable material. The material comprises, by weight, 3-4 parts of methyl tin mercaptide, 1-2 parts of solydimethyl siloxane, 4-7 parts of polyethyleneimine, 6-9 parts of ethylparaben, 570-600 parts of polyvinyl chloride, 17-20 parts of fulvic acid, 3-5 parts of calcium hydrophosphate, 0.06-0.1 part of sodium iodide, 80-100 parts of isopropanol, 70-100 parts of soapstone, 2-3 parts of sp80, 0.8-2 parts of epoxy chloropropane, 20-30 parts of lactide, 0.2-0.25 part of L-arginine, 1-2 parts of sodium mercaptobenzothiazole, 3-4 parts of lanolin, 1-2 parts of polyoxyethylene castor oil and 3-5 parts of chlorinated paraffin. According to the cable sheath material, the polyvinyl chloride modified by the methyl tin mercaptide is adopted so that the stability of a finished product can be well improved. The finished material is good in high and low temperature resistance, high in flame redardance and high in safety, and can effectively reduce fire risks.

Owner:HEFEISHI SHENZHAO ELECTRONICS

Sheath material for cable auxiliary cooling tube and preparation method for sheath material

InactiveCN105111607AImprove barrier propertiesProtectivePlastic/resin/waxes insulatorsInsulated cablesSodium iodideArginine

The invention discloses a sheath material for a cable auxiliary cooling tube. The sheath material is prepared from the following raw materials in parts by weight: 1-2 parts of magnesium stearate, 1-2 parts of chitosan, 20-30 parts of brominated polystyrene, 570-600 parts of polyvinyl chloride, 17-20 parts of fulvic acid, 0.06-0.1 part of sodium iodide, 40-50 parts of isopropanol, 70-100 parts of soapstones, 2-3 parts of sp80, 20-30 parts of lactide, 0.2-0.25 part of L-arginine, 10-13 parts of dioctyl sebacate and 0.7-1 part of formamide. The cable sheath material disclosed by the invention has good freezing resistance, is particularly suitable for being used in a low-temperature environment, is hard to crack and destroy, and is good in water resistance and temperature alternating resistance and long in service life.

Owner:HEFEISHI SHENZHAO ELECTRONICS

Cable material for submersible pump and preparation method for submersible pump

InactiveCN105111610AImprove barrier propertiesProtectivePlastic/resin/waxes insulatorsThioureaArginine

The invention discloses a cable material for an submersible pump. The cable material is prepared from the following raw materials in parts by weight: 10-17 parts of nitrile rubber, 570-600 parts of polyvinyl chloride, 17-20 parts of fulvic acid, 0.06-0.1 part of sodium iodide, 40-50 parts of isopropanol, 70-100 parts of soapstones, 2-3 parts of sp80, 20-30 parts of lactide, 0.2-0.25 part of L-arginine, 10-13 parts of coumarone, 2-4 parts of aluminium triphosphate, 0.4-1 part of diethanol amine, 0.1-0.2 part of ethylene thiourea, 2-4 parts of borax and 4-6 parts of triglycidyl isocyanurate. The cable sheath material disclosed by the invention can be suitable for severe environments such as high temperatures, high pressures, oil-gas corrosion and the like in an oil well, and is long in service life.

Owner:HEFEISHI SHENZHAO ELECTRONICS

Anti-corrosion and anti-aging cable material and preparation method thereof

InactiveCN105086221ASlow down the rate of thermal decompositionHigh thermal decomposition temperatureBenzotriazoleSodium diacetate

The invention discloses an anti-corrosion and anti-aging cable material. The cable material comprises, by weight, 3-6 parts of polyvinyl alcohol, 1-2 parts of sodium diacetate, 3-4 parts of calcium propionate, 2-4 parts of 2,6-ditertbutyl-4 methylphenol, 10-14 parts of benzotriazole, 570-600 parts of polyvinyl chloride, 17-20 parts of fulvic acid, 0.06-0.1 part of sodium iodide, 40-50 parts of isopropanol, 70-100 parts of saponite, 2-3 parts of sp802, 20-30 parts of lactide, 0.2-0.25 part of L-arginine and 14-20 parts of butyl benzyl phthalate. The added sodium diacetate and calcium propionate of the cable material have excellent anti-microbial and anti-corrosion performance, and therefore the cable material is applicable to humid and dark working environments and other poor working environments and is long in service life.

Owner:HEFEISHI SHENZHAO ELECTRONICS

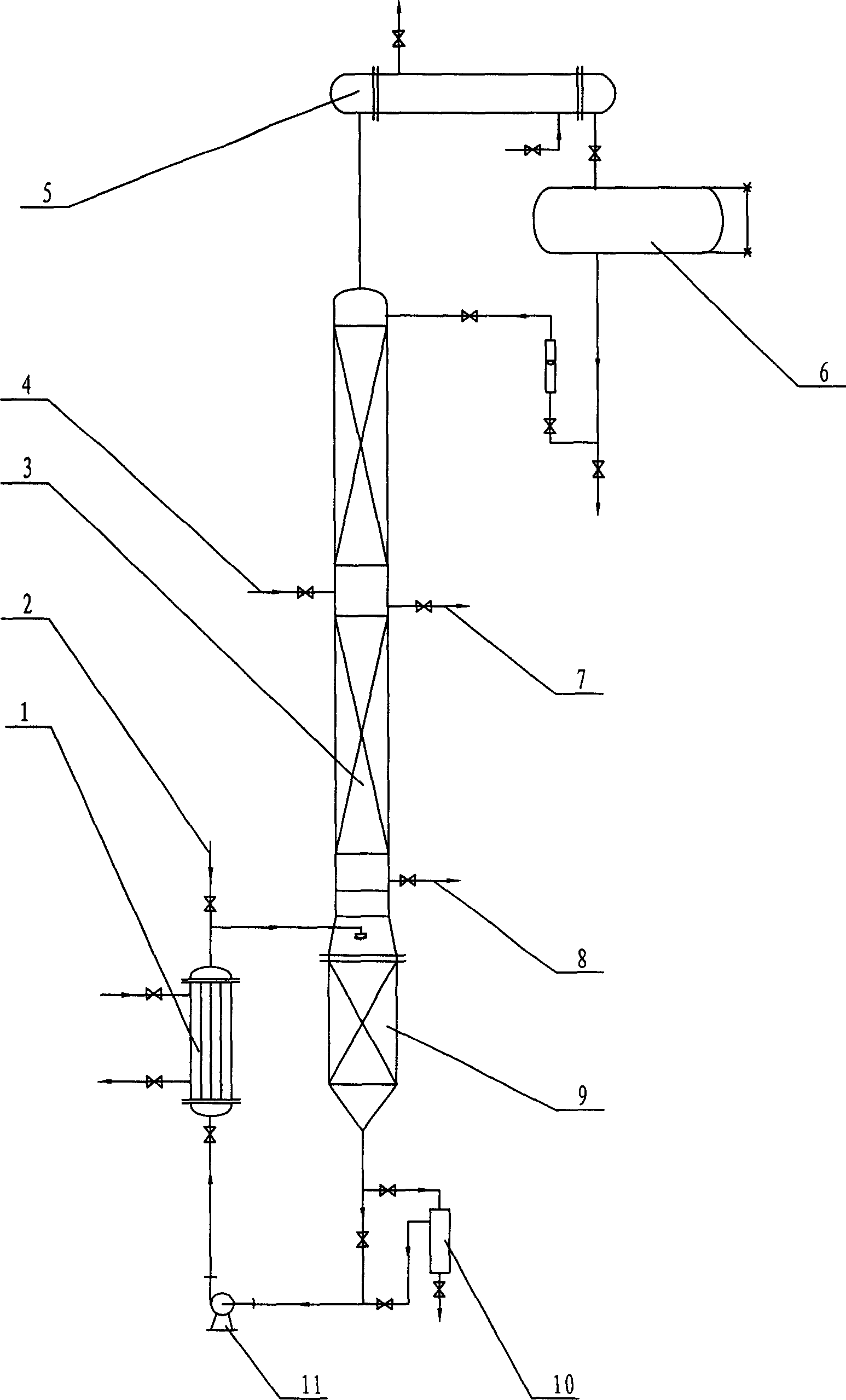

Wetting dry pot dynamic composite rectifying process of thermosensitive material

InactiveCN1241665CReduce thermal decomposition rateShort distillation timeDistillation in boilers/stillsFractional distillationProcess engineeringCirculating pump

A dynamic complex rectifying process for the thermosensitive material features that a wet-type dry still is used for direct contact heating, its rectifying apparatus is composed of rectifying tower, condenser, reflux tank, heat exchanger, circulating pump and phase separator. Said thermosensitive material is rectified forward and backward. Its advantages are short rectifying time and high output rate of product.

Owner:TIANJIN UNIV

Flame-retardant cable material and preparing method thereof

InactiveCN105086226AImprove barrier propertiesProtectivePlastic/resin/waxes insulatorsWaxDiphenyl phosphate

The invention discloses a flame-retardant cable material. The flame-retardant cable material is composed of, by weight, 2-3 parts of pentaerythritol, 6-10 parts of cresyl diphenyl phosphate, 2-4 parts of ammonium polyphosphate, 570-600 parts of polyvinyl chloride, 17-20 parts of fulvic acid, 0.06-0.1 part of sodium iodide, 40-50 parts of isopropanol, 70-100 parts of soapstone, 2-3 parts of sp80, 20-30 parts of lactide, 0.2-0.25 part of L-arginine, 3-7 parts of sasol wax, 1.6-2 parts of diisopropylethanolamine and 3-4 parts of quick lime. The cresyl diphenyl phosphate, the ammonium polyphosphate and the like which are added in the cable material have very good flame-retardant features, a better protection effect can be achieved, and the risk of fire disasters is reduced.

Owner:HEFEISHI SHENZHAO ELECTRONICS

Nanometer anti-oxidation cable material and preparation method thereof

InactiveCN105086227AImprove barrier propertiesProtectivePlastic/resin/waxes insulatorsSodium bicarbonateSodium iodide

The invention discloses a nanometer anti-oxidation cable material. The nanometer anti-oxidation cable material consists of, by weight, 10-15 parts of nanometer wollastonite powder, 10-16 parts of nanometer bauxite, 1-2 parts of pyromellitic dianhydride, 570-600 parts of polyvinyl chloride, 17-20 parts of fulvic acid, 0.06-0.1 part of sodium iodide, 40-50 parts of isopropyl alcohol, 60-80 parts of soapstone, 2-3 parts of sp80, 20-30 parts of lactide, 0.2-0.25 part of L-arginine, 2-4 parts of antioxidant 3002, 1-2 parts of benzotriazole, 10-13 parts of trioctyl trimellitate, 1-2 parts of ethoxylated alkyl phenol ammonium sulfate and 2-3 parts of sodium bicarbonate. The cable sheath material is prepared by blending the nanometer wollastonite powder and the nanometer bauxite, the compatibility of the raw materials is improved, the stability of a finished product is improved, and the nanometer anti-oxidation cable material is good in resistance to oxidation, high in surface strength, hard in texture and superior in overall performance.

Owner:HEFEISHI SHENZHAO ELECTRONICS

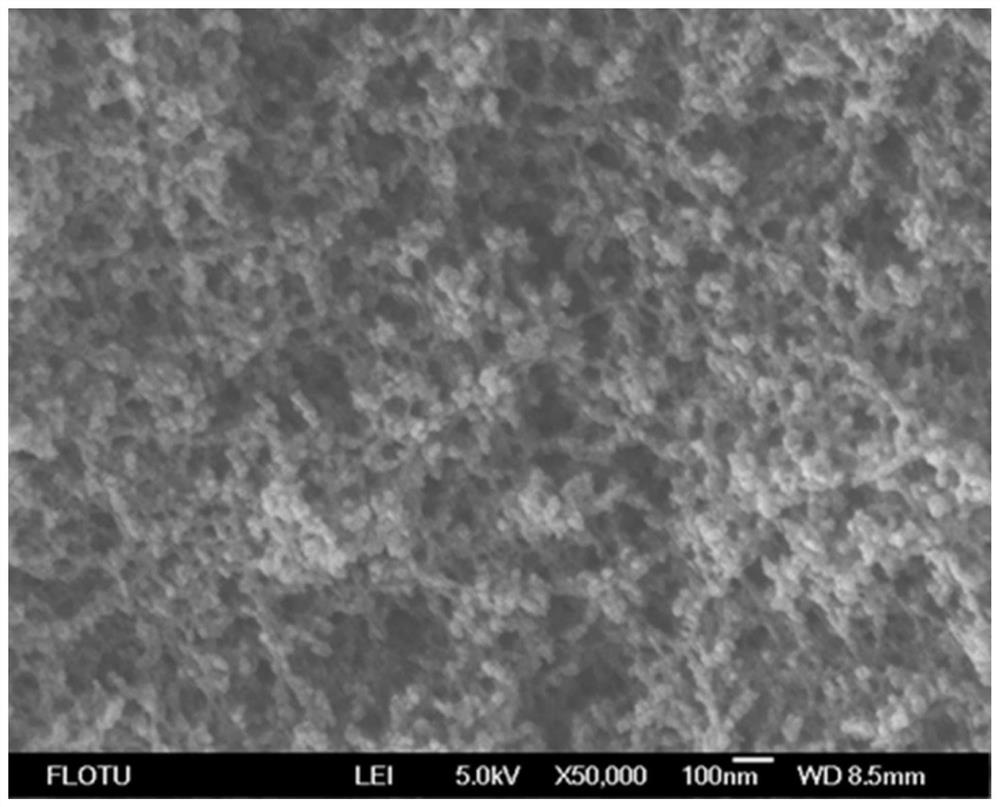

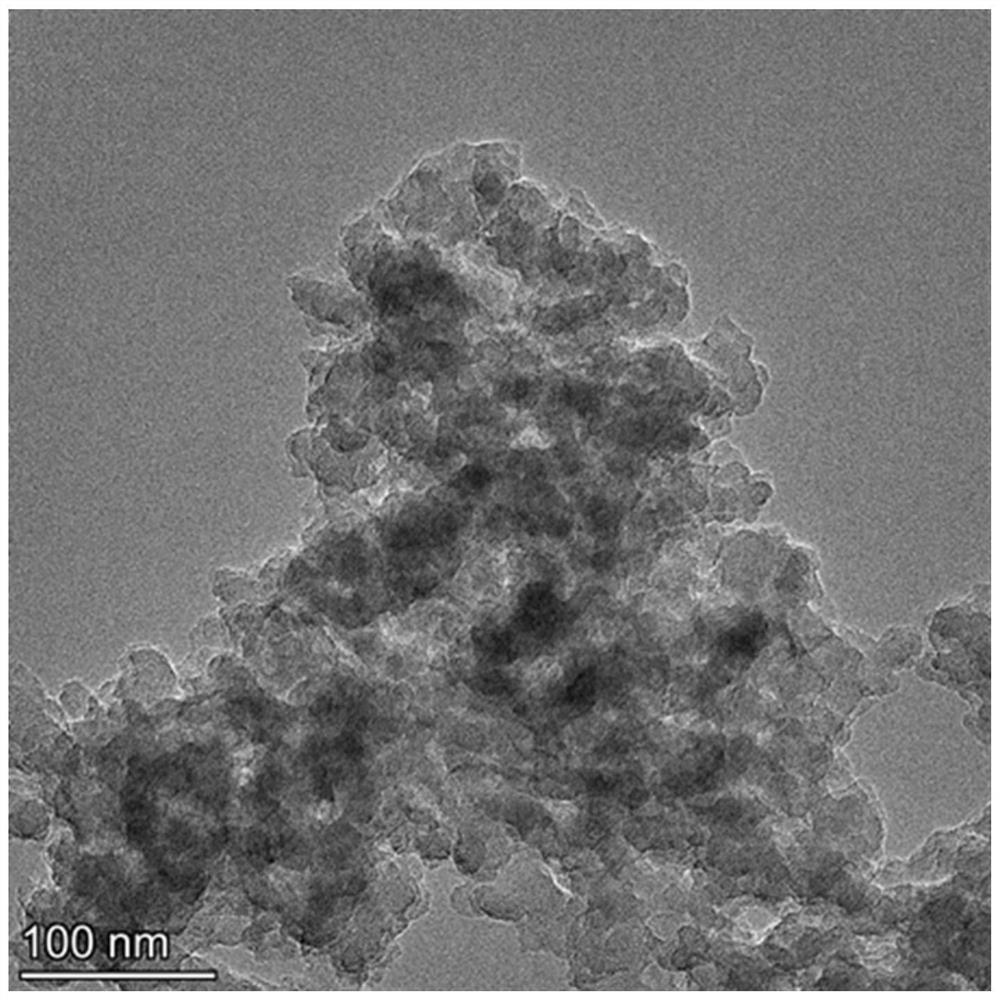

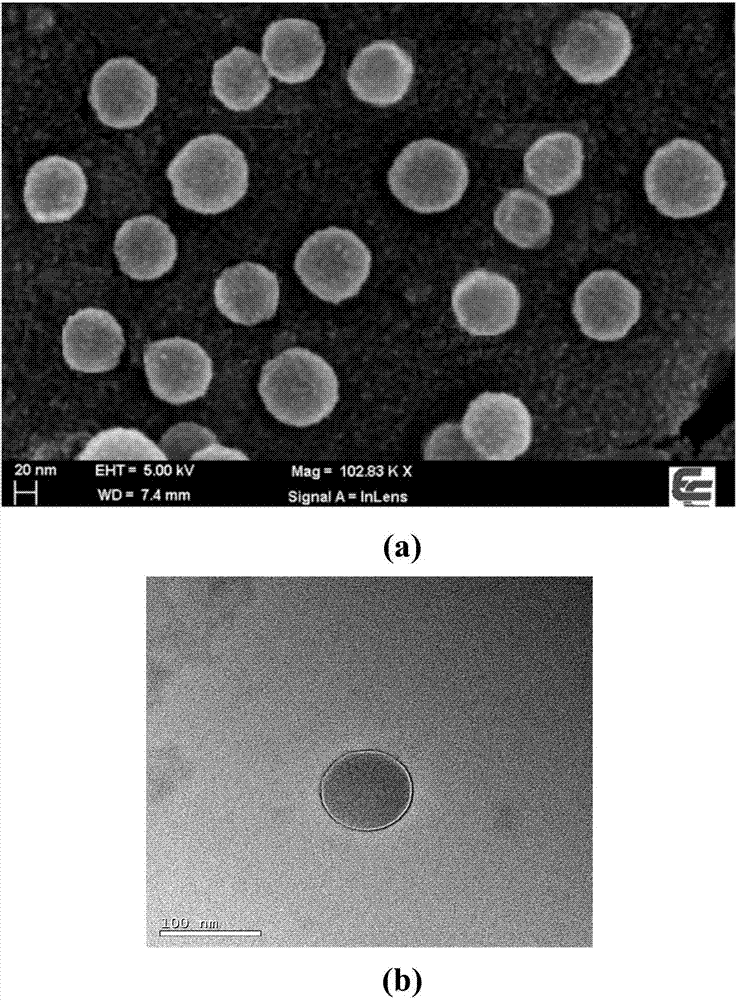

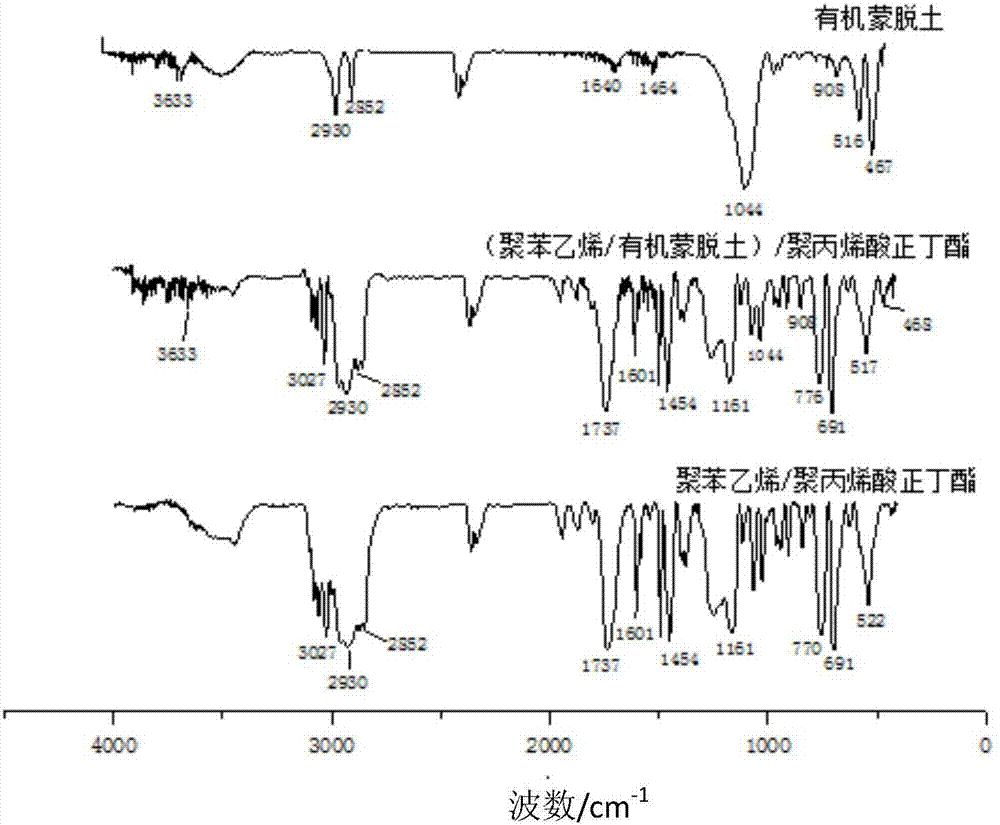

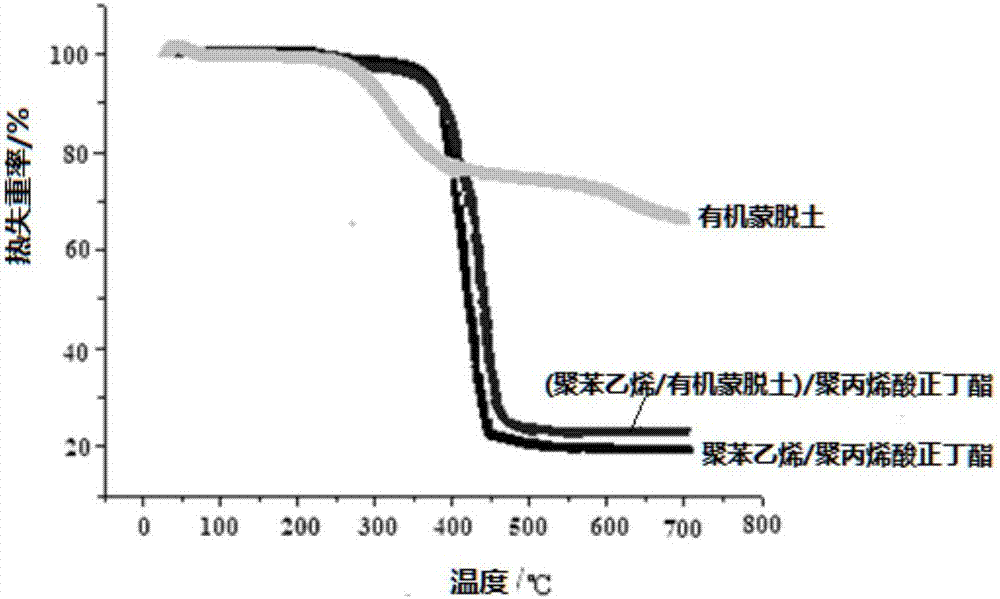

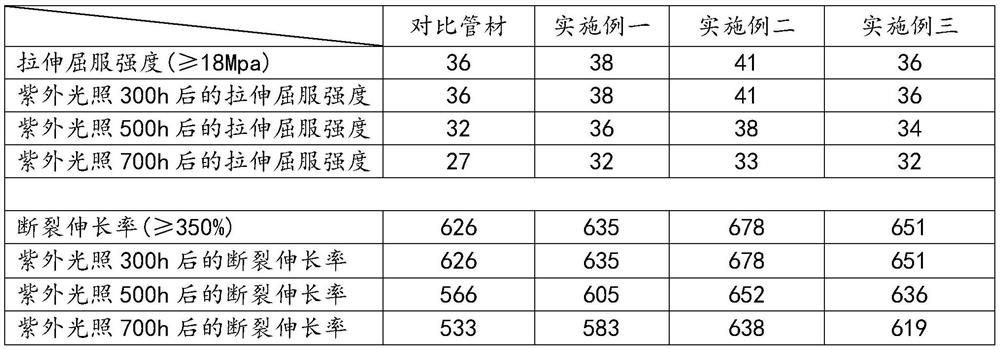

A polymer/clay nanocomposite material with core-shell structure and preparation method thereof

InactiveCN105111606BDeepen the formation mechanismBroaden the core-shell polymer/clay research systemPolymer sciencePhosphate

The invention relates to a polymer / clay nanocomposite material with a core-shell structure and a preparation method thereof. The composite material of the present invention is a core-shell structure with polystyrene / organic montmorillonite as the core layer and n-butyl polyacrylate as the coating shell layer; the appearance color is white; the polymer formed before demulsification The latex particles are spherical, with a particle size of 70-90nm, and after dyeing with phosphotungstic acid, it can be observed that the latex particles have a core-shell structure; the core layer of the composite material is composed of the following components in parts by mass through the seed emulsion polymerization method Prepared: 20-40 parts of styrene; 0-2 parts of acrylic acid; 0-2 parts of organic montmorillonite; the shell layer of the composite material is prepared by the seed emulsion polymerization method of the following components in parts by mass: acrylic acid positive 20-40 parts of butyl ester; 0-2 parts of acrylic acid. The core-shell structure polymer / clay nanocomposite material of the invention improves and enhances the thermal performance, processing performance and mechanical performance of the material.

Owner:ZHAOQING UNIV

A kind of rdp-coated nano attapulgite to prepare flame retardant polylactic acid composite material

InactiveCN104045985BImprove flame retardant performanceImprove mechanical propertiesDiphenyl phosphateCarbon layer

The invention discloses an antiflaming polylactic acid composite material prepared by RDP (resorcinol diphenyl phosphate) coated nano attapulgite. The RDP coated nano attapulgite is prepared from RDP and nano attapulgite which are taken as raw materials under an ultrasonic condition. The antiflaming polylactic acid composite material is prepared by virtue of the following steps: mixing the polylactic acid and RDP coated nano attapulgite at a mass ratio of (60-95):(40-5) at a high speed, extruding by use of an extruder, cooling and prilling. The antiflaming polylactic acid composite material has a simple formula, is remarkably improved in mechanical property, has good antiflaming efficiency and good heat stability, can form a stable and compact carbon layer in burning, has no molten drops, and generates less smoke.

Owner:NANJING UNIV OF SCI & TECH

Method for preparing cyclododecanone oxime

ActiveCN113548980AIncrease profitIncrease reaction rateOximes preparationChemical recyclingHydroxylaminePtru catalyst

The invention discloses a method for preparing cyclododecanone oxime. The method comprises the following steps: 1) heating a mixture of cyclododecanone, a solvent, a catalyst, a hydroxylamine protective agent and an auxiliary agent to a preset temperature; and (2) adding ammonia water and hydrogen peroxide into the mixture in the step (1) for reaction, and continuously aging until the reaction is finished after the charging is finished. A metal organic framework compound (MOFs) is used as a hydroxylamine protective agent, so that the utilization rate of hydrogen peroxide is increased; and amine oxide or ammonium carboxylate is used as an auxiliary agent, so that the ammoximation reaction rate is increased, and meanwhile, the thermal decomposition rate of hydrogen peroxide is reduced. By adopting the method, the conversion rate of the cyclododecanone can reach 99.5% or above and the utilization rate of the hydrogen peroxide can be increased to 90% or above after the reaction is carried out for 1 hour.

Owner:WANHUA CHEM GRP CO LTD

High-density polyethylene flame-retardant sub-pipe and preparation method thereof

The invention discloses a high-density polyethylene flame-retardant sub-pipe prepared from the following raw materials, by weight: 100 parts of high-density polyethylene, 3-6 parts of a plasticizer, 0.1-0.8 part of a 1010 type antioxidant, 0.2-1 part of a 168 type antioxidant, 0.3-2 part of calcium stearate, 0.2-3 part of 58 # paraffin, 8-15 parts of titanium dioxide, 4-8 parts of 2000-mesh lightcalcium carbonate and 3-6 parts of halogenated hydrocarbon. The polyethylene pipe provided by the invention has good ultraviolet resistance, can effectively delay the aging speed of the polyethylene pipe, also has good flame retardant property, and adapts to the use requirements of places such as high-rise buildings and coal mines. The invention further provides a preparation method of the high-density polyethylene flame-retardant sub-pipe, the preparation speed of the pipe can be increased, the raw materials are uniformly mixed in the reaction kettle, and the chemical reaction is stable.

Owner:苏州市皓月管业有限公司

High-performance environment-friendly aluminum alloy mould release agent

ActiveCN101554642BImprove heat resistanceReduce thermal decomposition rateFoundry mouldsFoundry coresHeat resistancePreservative

The invention discloses a high-performance environment-friendly aluminum alloy mould release agent which consists of modified organic silicone, grease synthetic ester, anti-rust inhibitor, preservative, surfactant and water. The high-performance environment-friendly aluminum alloy mould release agent adopts the special modified organic silicone and the grease as the composite lubricating mould release agent and is further provided with a variety of the anti-rust inhibitor, the preservative and the surfactant, and the product has excellent heat resistance performance and can greatly improve thehigh-temperature stability and the high-temperature mould release performance of the product and greatly reduce the occurrence of air holes.

Owner:QIDONG YUSHIRO CHEMICAL INDUSTRY CO LTD +1

A wet denitrification process and device for alkali furnace flue gas with absorbent recycling

ActiveCN108380017BMaintain vulcanizationThe recovery rate meetsGas treatmentDispersed particle separationBlack liquorCombustion

The invention discloses an alkaline furnace flue gas wet process denitration process and device capable of cyclically utilizing an absorbent. The process comprises the following steps that (1) alkaline recovery furnace flue gas is subjected to high-temperature electric dust removal, heat exchange temperature reduction and ozone oxidation, and is then conveyed into a wet process absorption tower; denitration absorption liquid in the absorption tower performs cyclical spraying absorption on flue gas; the purified flue gas is discharged out through a chimney; (2) slurry after the flue gas is subjected to spraying absorption is discharged out of the absorption tower; a denitrification agent is added into the slurry; sodium sulfate slurry after the denitrification treatment is conveyed into a black liquor concentration work procedure of the alkaline recovery furnace; concentrated sodium sulfate and black liquid mixed liquid is sprayed into the alkaline recovery furnace; combustion reductionis performed in the alkaline recovery furnace; a combustion reduction product is discharged and is then dissolved and causticized; denitration absorption liquid is regenerated again. The flue gas wetprocess denitration absorbent can be cyclically utilized; the denitration operation cost is low; the denitration absorbent is not consumed; no ozone escape exists; zero waste water discharging is realized.

Owner:HANGZHOU TIANLAN ENVIRONMENTAL PROTECTION ENG DESIGN

Silanized cable material and preparation method therefor

InactiveCN105111611AImprove barrier propertiesProtectivePlastic/resin/waxes insulatorsArginineSodium iodide

The invention discloses a silanized cable material which is prepared from the following raw materials in parts by weight: 1-2 parts of wool fat, 2-3 parts of gamma-chloropropyltrichlorosilane, 570-600 parts of polyvinyl chloride, 17-20 parts of fulvic acid, 0.06-0.1 part of sodium iodide, 3-4 parts of sodium alkyl benzene sulfonate, 40-50 parts of isopropanol, 70-100 parts of soapstones, 2-3 parts of sp80, 20-30 parts of lactide, 0.2-0.25 part of L-arginine and 14-20 parts of dibutyl maleate. The cable material disclosed by the invention is scratch resistant and fold resistant, has no marks if being folded and collided, and is good in machinability and flexibility.

Owner:HEFEISHI SHENZHAO ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com