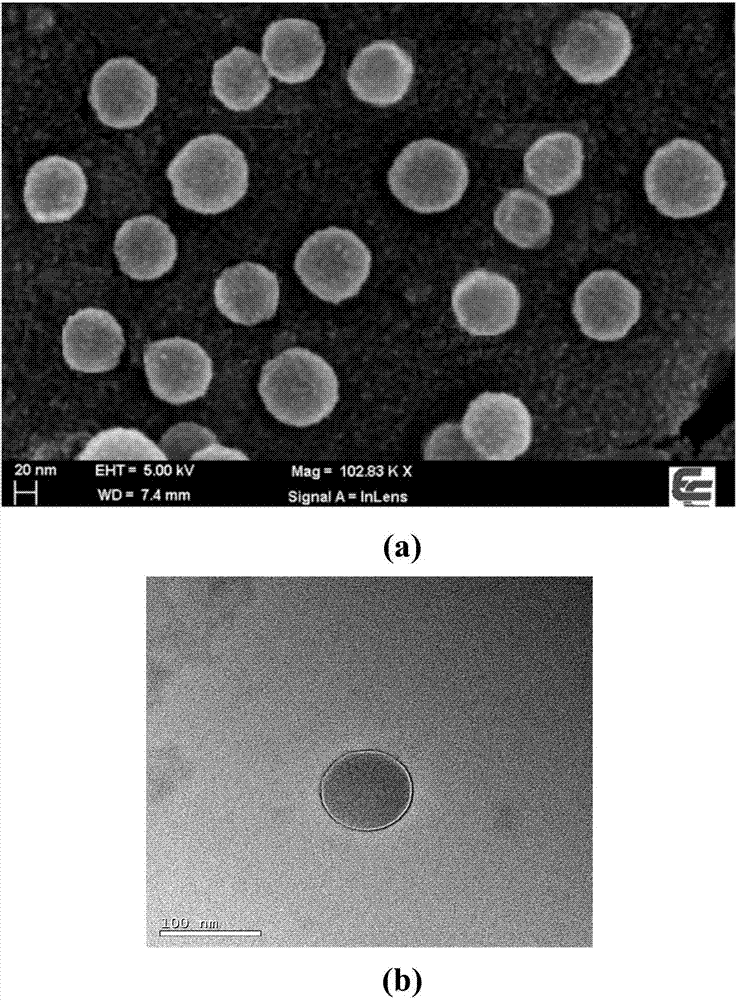

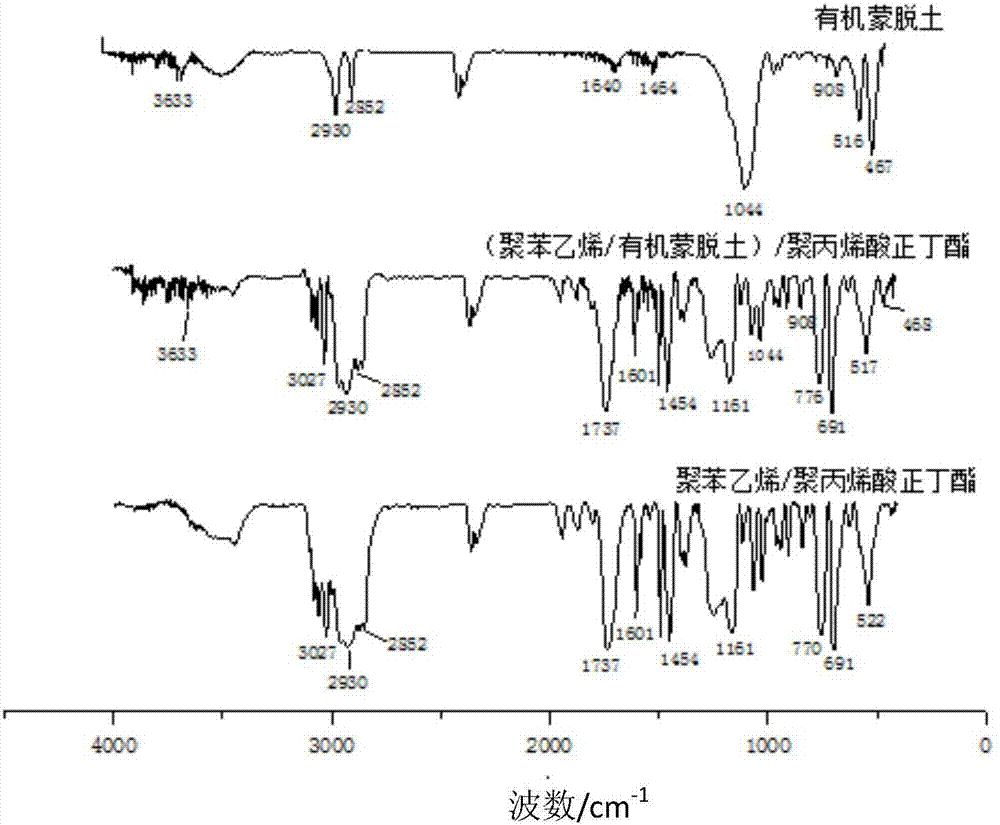

A polymer/clay nanocomposite material with core-shell structure and preparation method thereof

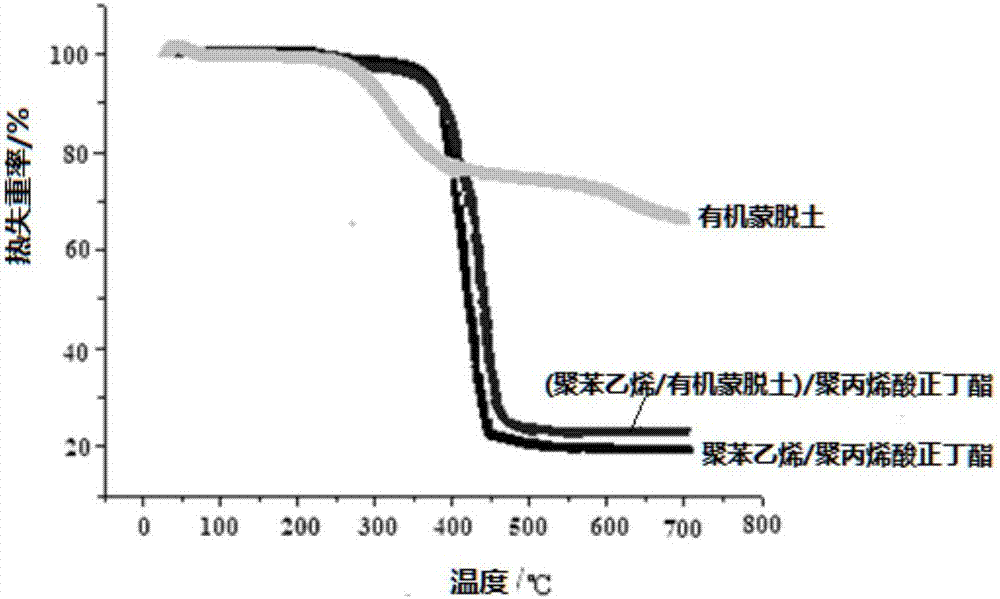

A technology of nano-composite materials and core-shell structure, applied in the field of materials, can solve the problems of insufficient core-shell polymer/clay composite materials, and achieve the effects of improved processing fluidity, slowed thermal decomposition rate, and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Preparation of the core-shell structure polymer / clay nanocomposite material of the present invention

[0036] (1) Fully stir 1 part of organic montmorillonite and 70% of the total mass of distilled water at 45°C for 1 hour;

[0037] (2) Mix 40 parts of styrene, 2 parts of acrylic acid, 7% of the core monomer mass of the composite emulsifier, 70% of the total mass of the co-emulsifier, and 8% of the total mass of distilled water, fully stirred and mixed at 60°C to obtain the core layer Monomer pre-emulsion;

[0038] (3) 20 parts of n-butyl acrylate, 0.6 parts of acrylic acid, 5% shell monomer mass of composite emulsifier, 30% of the total mass of co-emulsifier and 8% of the total mass of distilled water, fully stirred and mixed to obtain a shell mono Body pre-emulsion;

[0039] (4) Take 20% of the total mass from the nuclear layer monomer pre-emulsion obtained in step (2), and take 20% of the total mass from the nuclear layer initiator, stir and mix the two, and heat...

Embodiment 2

[0042] Example 2: Preparation of the core-shell structure polymer / clay nanocomposite material of the present invention

[0043] (1) Fully stir 0.5 part of organic montmorillonite and 40% of the total mass of distilled water at 40°C for 1 hour;

[0044] (2) Mix 20 parts of styrene, 1 part of acrylic acid, 7% of the core monomer mass of the composite emulsifier, 70% of the total mass of the co-emulsifier and 15% of the total mass of distilled water, and stir and mix thoroughly at 50℃ to obtain the core layer Monomer pre-emulsion;

[0045] (3) 20 parts of n-butyl acrylate, 1 part of acrylic acid, 5% shell monomer mass of composite emulsifier, 30% of the total mass of co-emulsifier and 15% of the total mass of distilled water, fully stirred and mixed to obtain a shell mono Body pre-emulsion;

[0046] (4) Take 15% of the total mass from the nuclear layer monomer pre-emulsion obtained in step (2), and take 15% of the total mass from the nuclear layer initiator, stir and mix the two, and he...

Embodiment 3

[0049] Example 3: Preparation of the core-shell structure polymer / clay nanocomposite material of the present invention

[0050] (1) Mix 0.8 parts of organic montmorillonite and 75% of the total mass of distilled water at 40°C for 1 h;

[0051] (2) Mix 30 parts of styrene, 1.5 parts of acrylic acid, 7% of the core monomer mass of the composite emulsifier, 65% of the total mass of the co-emulsifier and 6% of the total mass of distilled water, and stir and mix thoroughly at 50℃ to obtain the core layer Monomer pre-emulsion;

[0052] (3) 30 parts of n-butyl acrylate, 1.5 parts of acrylic acid, 5% shell monomer mass of composite emulsifier, 35% of the total mass of co-emulsifier and 6% of the total mass of distilled water, fully stirred and mixed to obtain a shell mono Body pre-emulsion;

[0053] (4) Take 20% of the total mass from the nuclear layer monomer pre-emulsion obtained in step (2), and take 20% of the total mass from the nuclear layer initiator, stir and mix the two, and heat up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com