Microcapsule mildew-proof additive, composite material and electric-control element housing

A technology of composite materials and microcapsules, which is applied in the field of microcapsule anti-mildew additives, composite materials and electric control component shells, can solve the problems of mechanical property degradation, easy mildew, easy aging, etc., and reduce the probability of thermal decomposition and speed, the effect of delaying the conduction velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 10

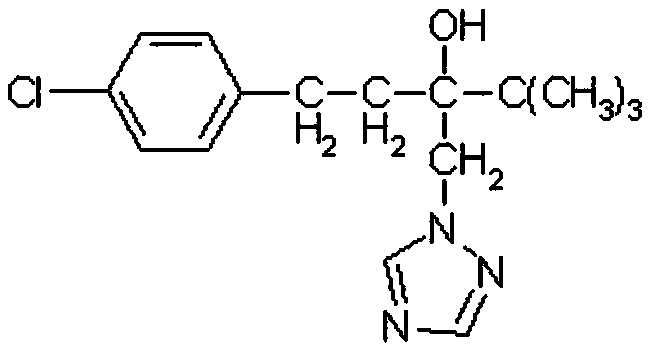

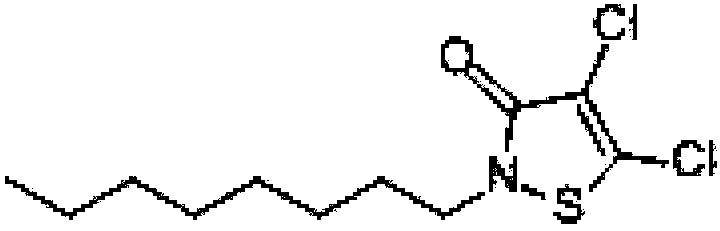

[0062] The microcapsule antifungal agent used in Example 10 was prepared by the following process. At 25°C, 800 g of the organic antifungal agent was placed in 20 L of deionized water in a stirring state and completely dissolved; slowly added 8 g of dodecylbenzene After the sodium sulfonate is completely dissolved, the stirring is stopped to obtain a solution; the solution is spray-dried by a spray dryer to obtain the microcapsule anti-mildew additive.

Embodiment 11

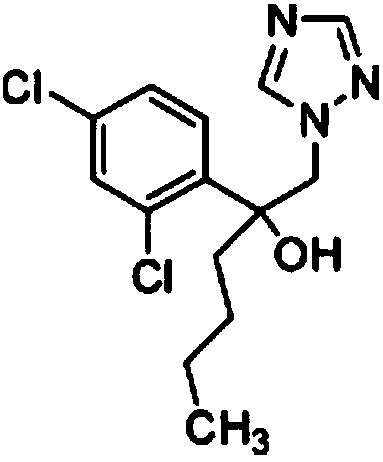

[0063] The microcapsule antifungal agent used in Example 11 was prepared by the following process. At the same time, 5L of deionized water, 10g of organic antifungal agent and 0.1g of sodium dodecylbenzenesulfonate were added to the bubble liquid film reactor at the same time , to prepare a microcapsule foam, and then filter and dry to obtain the microcapsule anti-mildew additive.

[0064] 2. Preparation of composite materials

[0065] Weigh the corresponding amount of materials according to the formula ratio in the table below, mix them to obtain a mixed material, then extrude the mixed material through a twin-screw extruder, cool, granulate, and dry to obtain a composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com