Antimony-free flame-retardant hot-melt adhesive film for FFCs and preparation method thereof

A technology of hot-melt adhesive film and wire rod, which is applied in the direction of heat-activated film/sheet, adhesive, film/sheet release coating, etc. It can solve the problems of inability to achieve flame retardant effect, insufficient flame retardant efficiency, and generation of corrosive gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0034] The antimony-free flame-resistant FFC wire rod of the present embodiment uses the hot-melt adhesive film, as figure 1 As shown, it includes a PET insulating layer 1, a precoat layer 2 and an adhesive layer 3, and the precoat layer 2 is arranged between the PET insulating layer 1 and the adhesive layer 3, and the thickness of the adhesive layer 3 is less than the thickness of the PET insulating layer 1;

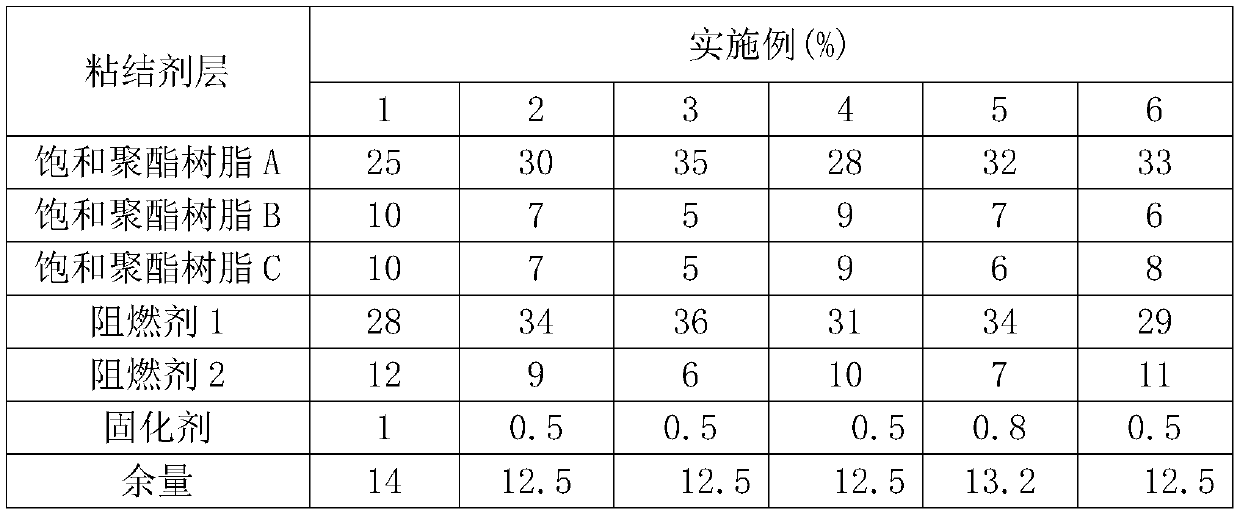

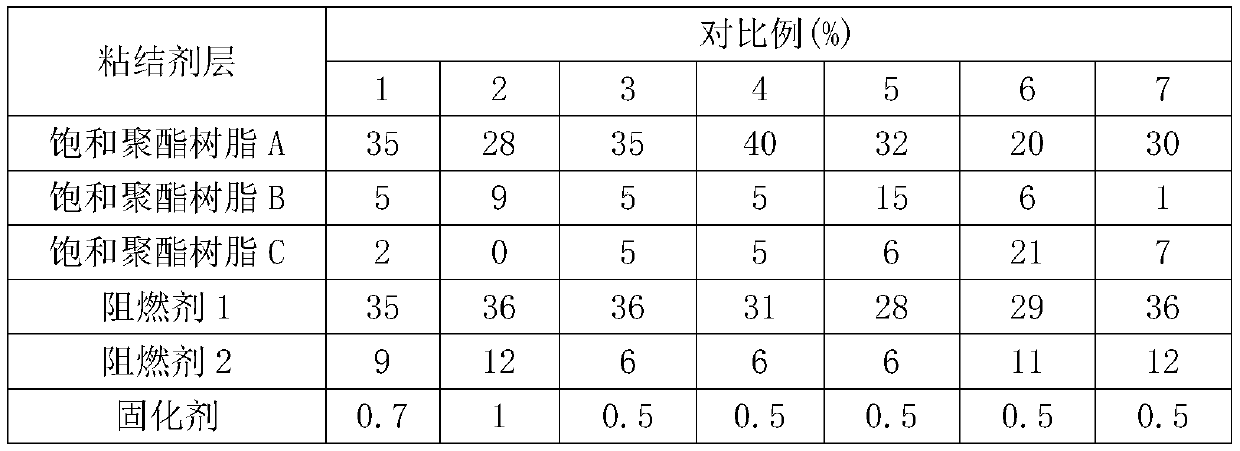

[0035] According to the percentage by weight, the raw materials of the adhesive layer 3 include: 25-35% saturated polyester resin A, 5-10% saturated polyester resin B, 5-10% saturated polyester resin C, 28-36% Flame retardant a, 6-12% flame retardant b, 0.5-1% curing agent and 12.5-14% balance;

[0036] The saturated polyester resin C is a DOPO phosphorous-modified flame-retardant saturated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com