PVC resin oil-soluble terminator and preparation method thereof

A technology of PVC resin and terminator, applied in the field of PVC resin additives, can solve the problems of high requirements for reaction equipment, complex preparation process, low production efficiency, etc., and achieves shortened reaction time, low reaction temperature, and low equipment requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

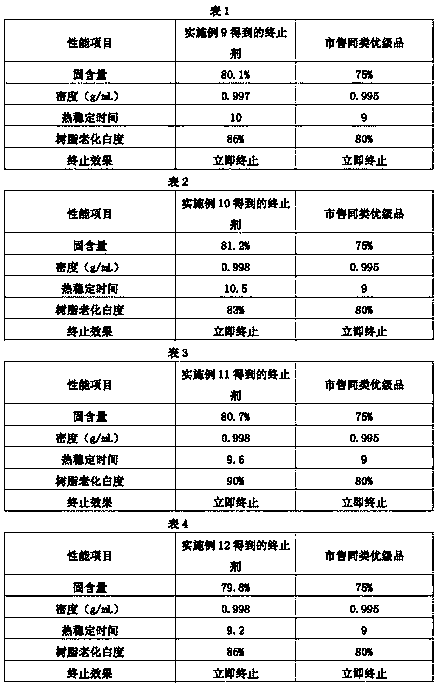

Examples

Embodiment 1

[0031] Embodiment 1, the PVC resin oil-soluble terminator, raw materials include 5 parts to 50 parts of epoxidized soybean oil, 10 parts to 30 parts of antioxidant, 1 part to 20 parts of solid terminator, and 5 parts of stabilizer in parts by weight. to 40 parts, 1 to 40 parts of plasticizer, 5 to 45 parts of styrene, 5 to 25 parts of solvent naphtha, and 5 to 40 parts of methanol solution.

Embodiment 2

[0032] Embodiment 2, the PVC resin oil-soluble terminator, raw materials include 5 parts or 50 parts of epoxidized soybean oil, 10 parts or 30 parts of antioxidant, 1 part or 20 parts of solid terminator, and 5 parts of stabilizer in parts by weight. Or 40 parts, 1 or 40 parts of plasticizer, 5 or 45 parts of styrene, 5 or 25 parts of solvent naphtha, 5 or 40 parts of methanol solution.

Embodiment 3

[0033] Embodiment 3, as the optimization of the above-mentioned embodiment, the PVC resin oil-soluble terminator is obtained according to the following steps: the first step, add epoxy soybean oil in the reaction kettle, start stirring and heating, and add antioxidant to the kettle at the same time , solid terminator, the temperature rises to 60 degrees Celsius to 90 degrees Celsius, and stir for 30 minutes to 60 minutes;

[0034] In the second step, adding a stabilizer to the product obtained in the first step, keeping the temperature at 60 to 90 degrees Celsius, and stirring for 30 to 60 minutes;

[0035] In the third step, the plasticizer is added to the solution obtained in the second step in the reaction kettle, the temperature is maintained at 60 to 90 degrees Celsius, and the mixture is stirred for 30 to 60 minutes;

[0036] In the fourth step, the temperature is lowered to 40°C to 60°C, adding styrene to the product obtained in the third step, keeping the temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com