Method for producing cross-linking powder nitrile-butadiene rubber with medium and high nitrile content

A powdered nitrile rubber and a production method technology, which is applied in the production field of medium and high nitrile content cross-linked powdered nitrile rubber, can solve the problems that cannot meet the high requirements of high temperature resistant train brake shoes, cannot guarantee the high temperature resistance of products, and achieve improved Processing stability, good termination effect, and the effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

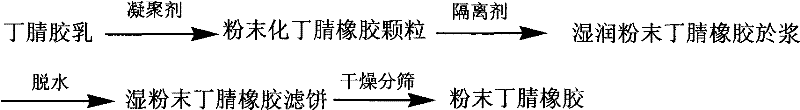

Method used

Image

Examples

Embodiment 1

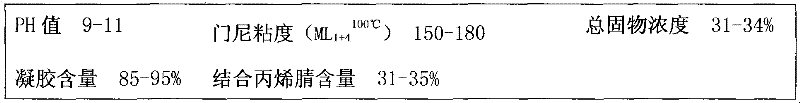

[0030] (1) Synthesis of nitrile mucilage:

[0031] First, the polymerization kettle is evacuated, and 140 parts of soft water are dropped into successively, 6 parts of composite emulsifiers composed of potassium stearate-potassium oleate, wherein the mass ratio of potassium stearate and potassium oleate is 2: 1, and the diffusing agent sub 1 part of sodium methanesulfonate, 0.2 part of buffer potassium carbonate, 0.4 part of molecular weight modifier tertiary dodecyl mercaptan, after stirring for 10 minutes, add 31 parts of acrylonitrile, 0.1 part of initiator potassium persulfate, pump with nitrogen Vacuum is repeated three times, 69 parts of butadiene is added, and the reaction time is 17-20 hours at a reaction temperature of 29-63°C and a reaction pressure of 0.2-0.52Mpa. The reaction is divided into three stages: the first stage, the temperature is raised to 38-39°C, and the reaction is started; the second stage, when the conversion rate reaches 68%, the temperature is rai...

Embodiment 2

[0040] In the synthesis step of nitrile mortar in embodiment 1, add 180 parts of soft water, 4 parts of composite emulsifier potassium stearate-potassium oleate, 35 parts of acrylonitrile, 65 parts of butadiene, other process formulas are the same as in Example 1.

[0041] The performance index of gained nitrile mortar is: pH value 10.6, Mooney viscosity (ML 1+4 100℃ ) 172, the total solid concentration is 32.8%, the gel content is 89%, and the combined acrylonitrile content is 32.6%.

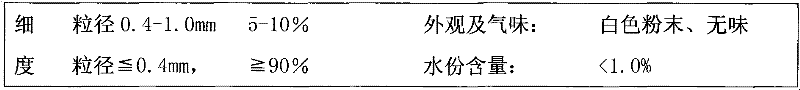

[0042] After isolation into powder and dehydration and drying, the resulting product index is within the control range shown in Table 2.

Embodiment 3

[0044] In the synthesis step of nitrile glue in embodiment 1, add 0.1 part of composite terminator (the mixed solution of diethylhydroxylamine, hydroxylammonium sulfate, potassium hydroxide and soft water, its mass ratio is 3: 2: 2: 70) , other process formulas are with embodiment 1.

[0045] The performance index of gained nitrile mortar is: pH value 10.2, Mooney viscosity (ML 1+4 100℃ ) 170, the total solid concentration is 31.9%, the gel content is 87%, and the combined acrylonitrile content is 33.5%.

[0046] After isolation into powder and dehydration and drying, the resulting product index is within the control range shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com