Organic stannic acid intercalation calcium/zinc-aluminum rare earth hydrotalcite composite heat stabilizer for hard PVC and preparation method thereof

A technology of compounding thermal stabilizer and hydrotalcite, applied in the field of thermal stabilizer for PVC, can solve problems such as poor thermal stability, and achieve the effects of low cost, significant social and economic benefits, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] According to the preparation method of the organic stannoic acid intercalated calcium / zinc-aluminum rare earth hydrotalcite composite heat stabilizer for rigid PVC in the second aspect of the present invention, it is used to prepare the organic stannic acid intercalated calcium / zinc-aluminum in the first aspect of the present invention The rare earth hydrotalcite composite thermal stabilizer comprises the steps of: (1) dissolving calcium salt, aluminum salt and rare earth salt in the deCO 2 solution in deionized water, while sodium hydroxide and organostannic acid were dissolved in deCO 2 In a mixed solution of deionized water and ethanol, where n(NaOH) / [n(M 2+ )+n(M 3+ )]=2.5~3, n(organic stannic acid) / n(M 3+ )=2~2.5, n is the amount of substance, M + is a metal ion, M 3+ Represents all the trivalent metal ions in the solution; (2) in N 2The protection and water bath are at a temperature of 60°C to 70°C. Place the two solutions of step (1) in a constant temperatur...

Embodiment 1

[0031] Step (1): Weigh 32.8g calcium nitrate, 37.5g aluminum nitrate, 5.2g lanthanum nitrate and dissolve in 2 In deionized water, weigh and weigh 36.0g sodium hydroxide, 87.7g dibutyltin dimaleic acid dissolved in deCO2 2 in a mixed solution of deionized water and ethanol.

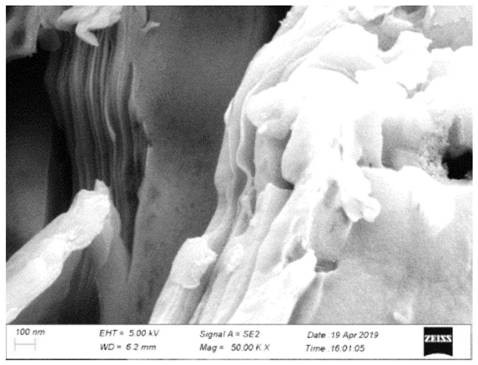

[0032] Step (2): at N 2 The temperature of the protection and water bath is 70°C. Put the above two solutions into a constant temperature dropping funnel, and drop them into a four-necked flask using the double drop method. Increase the reaction temperature to 85°C, stir, and keep the pH of the reaction solution at 11. , Reflux for 3 hours after the dropwise addition, then add the above solution into the hydrothermal kettle, sink at 120°C for 6 hours, filter with suction, and wash the solution to be neutral. After drying and grinding, a white powder, that is, dibutyltin dimaleic acid intercalated calcium aluminum lanthanum hydrotalcite is obtained.

[0033] Step (3): replace calcium nitrate with 59.4g ...

Embodiment 2

[0036] Step (1): Weigh 16.7g calcium chloride, 6.7g aluminum chloride, 2.6g cerium nitrate and dissolve in 2 In deionized water, weigh 24.0g sodium hydroxide and 21.5g butyl stannic acid in deCO2 2 in a mixed solution of deionized water and ethanol.

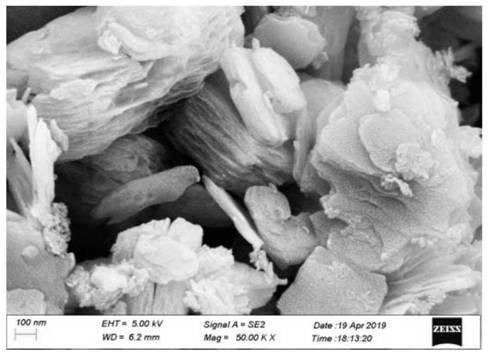

[0037] Step (2): at N 2 The temperature of the protection and water bath is 65°C. The above two solutions are respectively placed in a constant temperature dropping funnel, and are added dropwise to a four-necked flask by the double drop method. The reaction temperature is increased to 80°C, stirred, and the pH of the reaction solution is maintained at 12 , Reflux for 2 hours after the dropwise addition, then add the above solution into the hydrothermal kettle, sink at 120°C for 5 hours, filter with suction, and wash the solution to be neutral. After drying and grinding, a white powder is obtained, that is, butyl stannic acid intercalated calcium aluminum cerium hydrotalcite.

[0038] Step (3): Substitute 20.4 g of zinc chlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com