Barium-cadmium-zinc composite stabilizer and preparation method thereof

A composite stabilizer, barium cadmium technology, applied in the field of barium cadmium zinc composite stabilizer and its preparation, stabilizer, can solve the problems of opaque products, strong odor, high toxicity of lead salts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

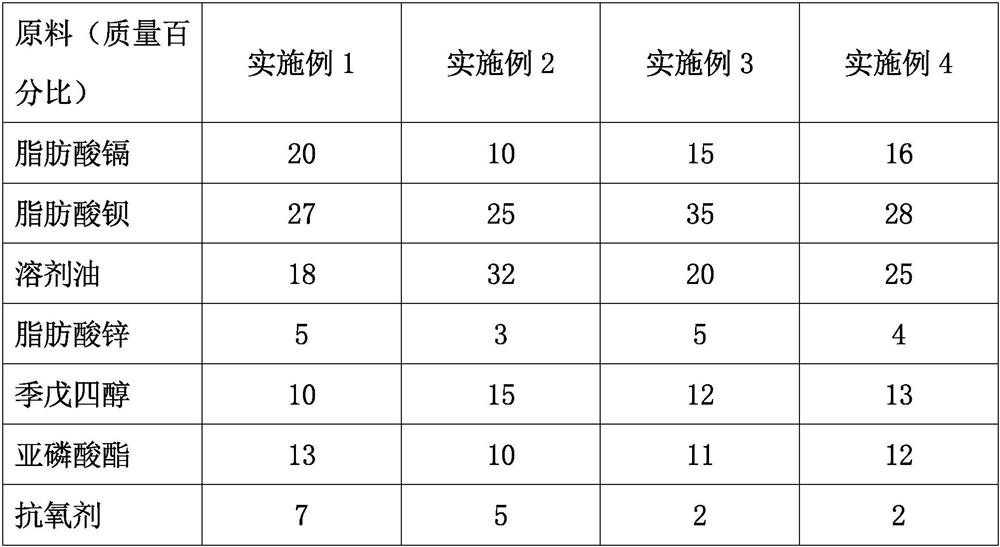

Examples

preparation example 1

[0033] The raw materials are obtained according to the mass percentage of each component in Example 4, put into an enamel container, and under constant stirring, the temperature is raised to 120°C, and the heat preservation and stirring are continued for 60 minutes. After the materials are completely dissolved, vacuum dehydration is carried out. Continue stirring to 60°C, filter to remove impurities, and obtain a brown or golden yellow liquid, which is the barium-cadmium-zinc composite stabilizer.

preparation example 2

[0035] The raw materials are obtained according to the mass percentage of each component in Example 4, put into the enamel container, and under constant stirring, the temperature is raised to 120°C, and the heat preservation and stirring are continued for 75 minutes. After the materials are completely dissolved, vacuum dehydration is carried out. Continue stirring to 65°C, remove impurities by filtration, and obtain a brown or golden yellow liquid, which is the barium-cadmium-zinc composite stabilizer.

preparation example 3

[0037] The raw materials are obtained according to the mass percentage of each component in Example 4, put into an enamel container, and under constant stirring, the temperature is raised to 120°C, and the heat preservation and stirring are continued for 90 minutes. After the materials are completely dissolved, vacuum dehydration is carried out. Continue stirring to 70°C, filter to remove impurities, and obtain a brown or golden yellow liquid, which is the barium-cadmium-zinc composite stabilizer.

[0038] The performance test result of each preparation example is as shown in table 5:

[0039] table 5

[0040] Static stability time at 180°C 180℃ dynamic stability time Congo red test (min) Preparation Example 1 73 61 58 Preparation example 2 75 62 62 Preparation example 3 74 60 61

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com