Mg-Ca-Zn-Al four-component hydrotalcite heat stabilizer

A heat stabilizer and hydrotalcite technology, applied in fibrous fillers, inorganic pigment treatment, chemical instruments and methods, etc., can solve the problems of rising raw material and power costs, increasing production costs, and prolonging the production process to achieve low cost, Improved thermal stability and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

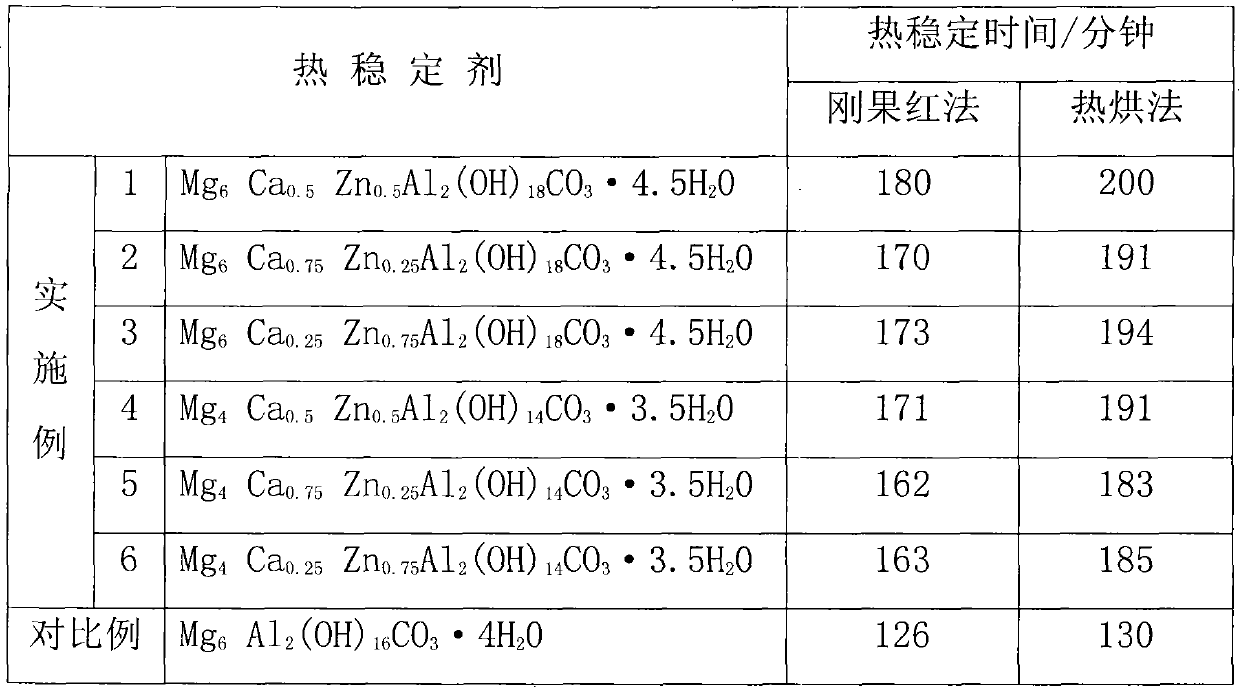

Examples

preparation example Construction

[0038] The preparation method of above-mentioned thermal stabilizer, its step is as follows:

[0039] a) Preparation of mixed salt solution

[0040] Add the soluble salts of magnesium, zinc, and aluminum into the stirring water at 60±5°C successively according to the set mass ratio of metal elements a:c:d of 2~4:0.05~0.5:1 to form a mixed salt solution , the total concentration of the three metal ions is 1.5-2.5mol / L;

[0041] b) Calcium salt solution preparation

[0042] Dissolve the soluble calcium salt in water, the dosage is 0.05-0.5:1 according to the mass ratio b:d of calcium and aluminum, and the concentration is 0.4-1.0mol / L;

[0043] c) Preparation of mixed lye

[0044] NaOH and Na 2 CO 3 Dissolve in water to make a mixed alkali solution, the amount of NaOH is 2 to 2.5 times the total moles of the above four metals, NaOH 2 CO 3 The dosage is 1 / 2~5 / 7 of the moles of aluminum ions, and the concentration of hydroxide in the mixed lye is 3.7~5.5mol / L;

[0045] d) ...

Embodiment 1

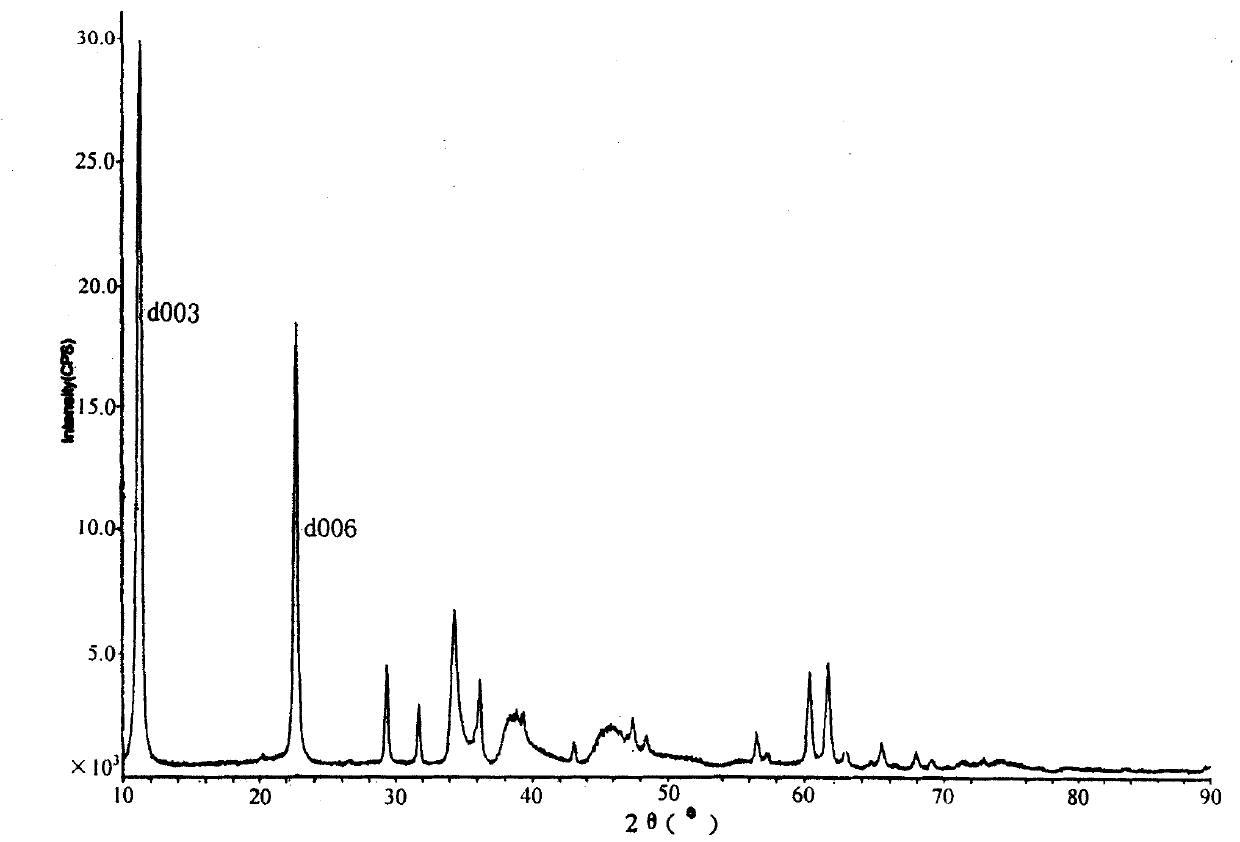

[0061] Mix 150mL of 6.6M NaOH solution with 60mL of 1M NaOH 2 CO 3 Add the solution into an 800mL stainless steel reaction kettle to make a mixed lye, and heat it to 60±5°C while stirring. 75 mL of 4M MgSO 4 solution, 62.5mL 0.8M Al 2 (SO 4 ) 3 solution and 50mL 0.5M ZnSO 4 After the solution is mixed, it is poured into the vigorously stirred mixed lye at one time, and then 50mL of 0.5M CaCl 2 The solution is poured into it. Raise the temperature to 95-97°C and keep for 3 hours, during which the pH is controlled at 12-14. Seal the reaction kettle, continue to heat up to 120±5°C, keep it for 3 hours, cool down to below 75°C, filter the feed liquid, wash the filter cake until the pH of the lotion is 7~8, dry and pulverize to obtain Mg-Ca-Zn-Al quaternary The hydrotalcite-like powder is 34.9g, and its chemical formula is determined by elemental analysis:

[0062] Mg 0.666 Ca 0.056 Zn 0.056 al 0.222 (OH) 2 (CO 3 ) 0.111 0.5H 2 o

[0063] or: Mg 6 Ca 0.5 Zn 0.5...

Embodiment 2

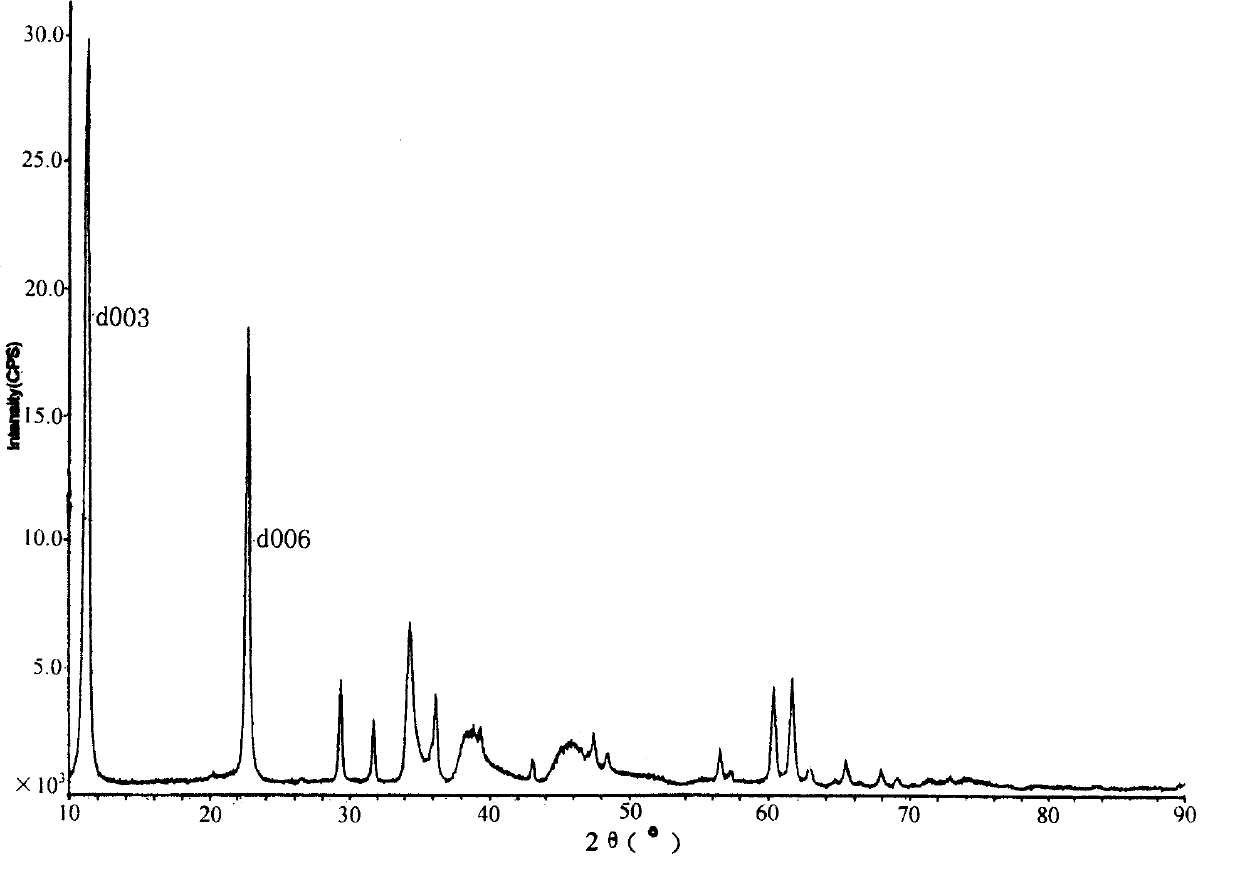

[0065] Mix 150mL of 6.6M NaOH solution with 60mL of 1M NaOH 2 CO 3 Add the solution into an 800mL stainless steel reaction kettle to make a mixed lye, and heat it to 60±5°C while stirring. 75 mL of 4M MgCl 2 solution, 62.5mL of 1.6M AlCl 3 solution and 25mL of 0.5M ZnCl 2 After the solution is mixed, it is poured into the vigorously stirred mixed lye at one time, and then 75mL of 0.5M CaCl 2 The solution is poured into it. Raise the temperature to 95-97°C and keep for 3 hours, during which the pH is controlled at 12-14. Seal the reaction kettle, continue to heat up to 120±5°C, keep it for 3 hours, cool down to below 75°C, filter the feed liquid, wash the filter cake until the pH of the lotion is 7~8, dry and pulverize to obtain Mg-Ca-Zn-Al quaternary The hydrotalcite-like powder is 34.6g, and its chemical formula is determined by elemental analysis:

[0066] Mg 0.666 Ca 0.084 Zn 0.028 al 0.222 (OH) 2 (CO 3 ) 0.111 0.5H 2 O or: Mg 6 Ca 0.75 Zn 0.25 al 2 (OH) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com