Middle material layer of plastic floor and plastic floor obtained by the same

A technology of plastic floor and material layer, which is applied in the direction of construction, building structure, floor, etc. It can solve the problems that the edge of the product is easy to become brittle, damaged, and the toughness is reduced, so as to achieve improved weather resistance, good flatness, and improved flexibility. The effect of sex and pull

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

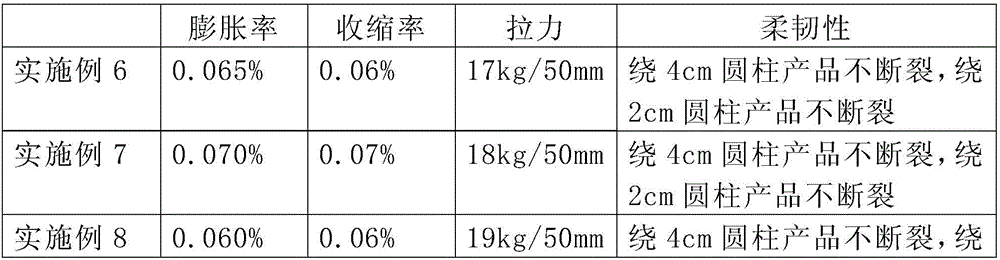

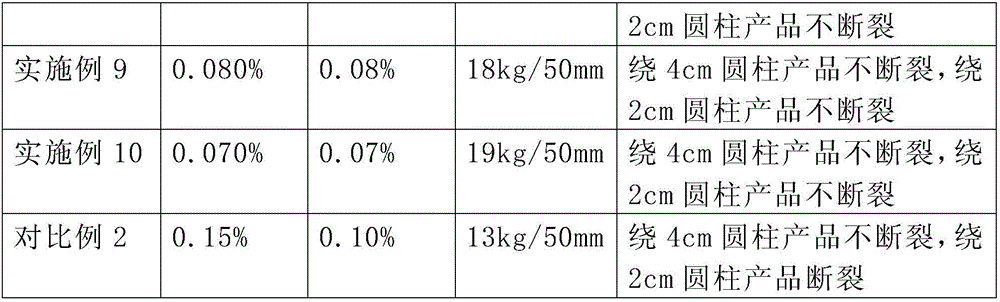

Examples

Embodiment 1

[0019] A middle material layer of a plastic floor, made of the following raw materials in parts by weight: 90 parts of polyvinyl chloride, 28 parts of plasticizer, 2.1 parts of stabilizer, 0.2 parts of carbon black, 455 parts of calcium carbonate, 6.2 parts of chlorinated polyethylene share. Wherein, the plasticizer is dioctyl terephthalate, and the stabilizer is a calcium-zinc composite stabilizer.

[0020] The middle material layer is prepared by the following method: mix the raw materials polyvinyl chloride, plasticizer, stabilizer, carbon black and chlorinated polyethylene according to the above ratio, mix evenly, add calcium carbonate to continue mixing, mix evenly, add closed rubber mixing In the machine, the temperature of the closed rubber mixer is controlled at 180°C, and the material is discharged after banburying for 5 minutes. The thickness is adjusted on the open mill, and the temperature of the sheet is controlled at 45°C. The sheet is calendered to obtain the mi...

Embodiment 2

[0022] A middle material layer of a plastic floor, made of the following raw materials in parts by weight: 92 parts of polyvinyl chloride, 30 parts of plasticizer, 2.5 parts of stabilizer, 0.3 parts of carbon black, 460 parts of calcium carbonate, 8 parts of chlorinated polyethylene share. Wherein, the plasticizer is dioctyl terephthalate, and the stabilizer is a calcium-zinc composite stabilizer.

[0023] The middle material layer is prepared by the following method: mix the raw materials polyvinyl chloride, plasticizer, stabilizer, carbon black and chlorinated polyethylene according to the above ratio, mix evenly, add calcium carbonate to continue mixing, mix evenly, add closed rubber mixing In the machine, the temperature of the closed rubber mixer is controlled at 180°C, and the material is discharged after banburying for 5 minutes. The thickness is adjusted on the open mill, and the temperature of the sheet is controlled at 45°C. The sheet is calendered to obtain the midd...

Embodiment 3

[0025] A middle material layer of a plastic floor, made of the following raw materials in parts by weight: 93 parts of polyvinyl chloride, 28 parts of plasticizer, 3 parts of stabilizer, 0.4 part of carbon black, 455 parts of calcium carbonate, 9 parts of chlorinated polyethylene share. Wherein, the plasticizer is dioctyl terephthalate, and the stabilizer is a calcium-zinc composite stabilizer.

[0026] The middle material layer is prepared by the following method: mix the raw materials polyvinyl chloride, plasticizer, stabilizer, carbon black and chlorinated polyethylene according to the above ratio, mix evenly, add calcium carbonate to continue mixing, mix evenly, add closed rubber mixing In the machine, the temperature of the closed rubber mixer is controlled at 180°C, and the material is discharged after banburying for 5 minutes. The thickness is adjusted on the open mill, and the temperature of the sheet is controlled at 45°C. The sheet is calendered to obtain the middle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com