Cold-resistant polypropylene and preparation method thereof

A polypropylene and cold-resistant technology, applied in the field of polypropylene fibers, can solve the problems of cracking and short service life of polypropylene fibers, and achieve the effects of low viscosity, high plasticizer efficiency and good viscosity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

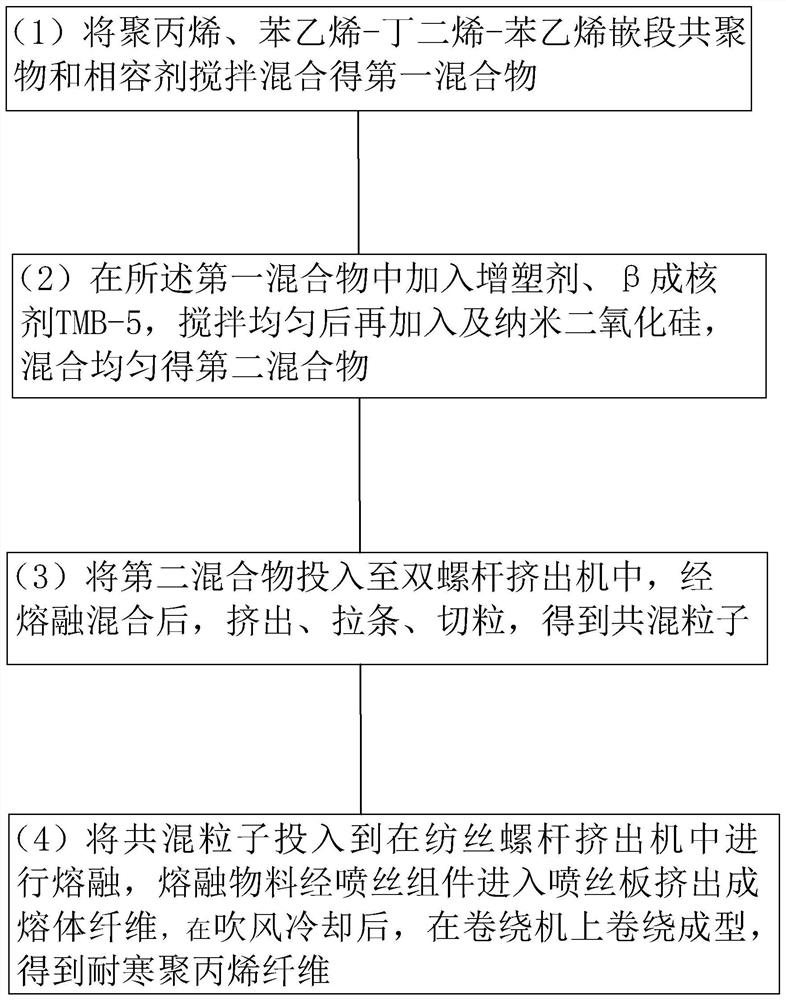

Method used

Image

Examples

Embodiment 1

[0044] A cold-resistant polypropylene made of the following raw materials: 50 parts of polypropylene, 15 parts of styrene-butadiene-styrene block copolymer, 5 parts of grafted maleic anhydride polyethylene, 15 parts of adipic acid di Octyl ester, 4 parts of β nucleating agent TMB-5 and 6 parts of nano silicon dioxide.

[0045] A preparation method of the above-mentioned cold-resistant polypropylene, comprising the following steps:

[0046] (1) Stir 50 parts of polypropylene, 15 parts of styrene-butadiene-styrene block copolymer and 5 parts of grafted maleic anhydride polyethylene at a stirring temperature of 105°C and a stirring speed of 500r / min 25min obtains the first mixture;

[0047] (2) Add 15 parts of dioctyl adipate, 4 parts of beta nucleating agent TMB-5 in the first mixture, add and 6 parts of nano silicon dioxide after stirring evenly, at a stirring temperature of 105°C and Under the stirring speed of 500r / min, stir 25min to obtain the second mixture;

[0048] (3) P...

Embodiment 2-5

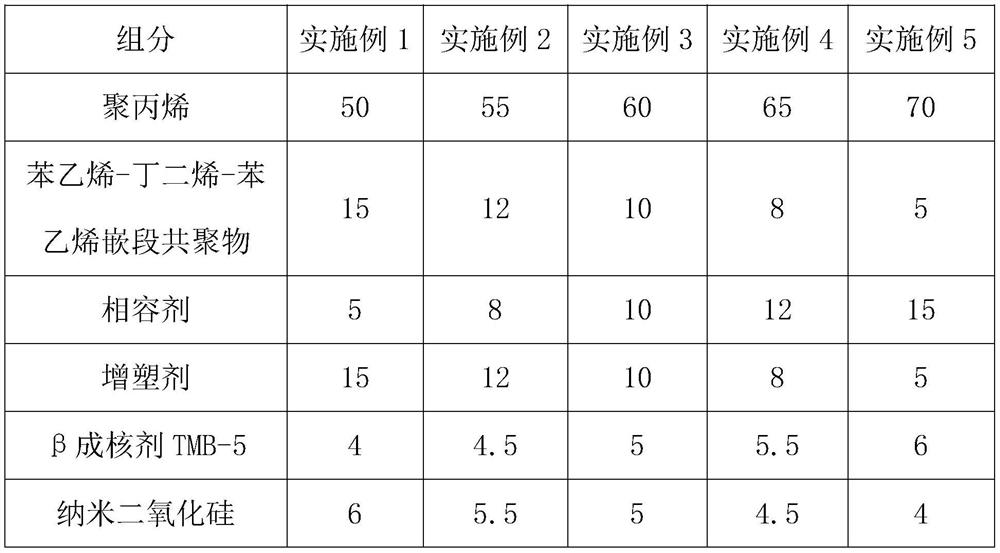

[0050] The difference from Example 1 is that the components of the raw materials and their corresponding parts by weight are different, as shown in Table 2.

[0051] Each raw material and parts by weight thereof in the table 2 embodiment 1-5

[0052]

Embodiment 6

[0053] Embodiment 6: The difference from Embodiment 1 is that the plasticizer adopts synthetic vegetable ester T60.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com