Nano PVC flame-retardant waterproof tarpaulin and preparation method thereof

A nano-flame-retardant and nano-technology, which is applied in the direction of textiles and papermaking, can solve the problems of broken skin and easy peeling off of PVC covering film, and achieve the effects of suppressing oil leakage, long thermal stability time, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

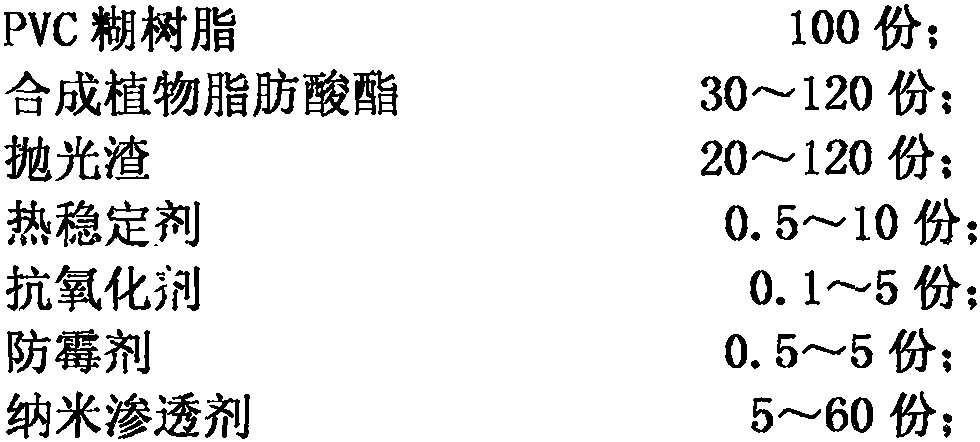

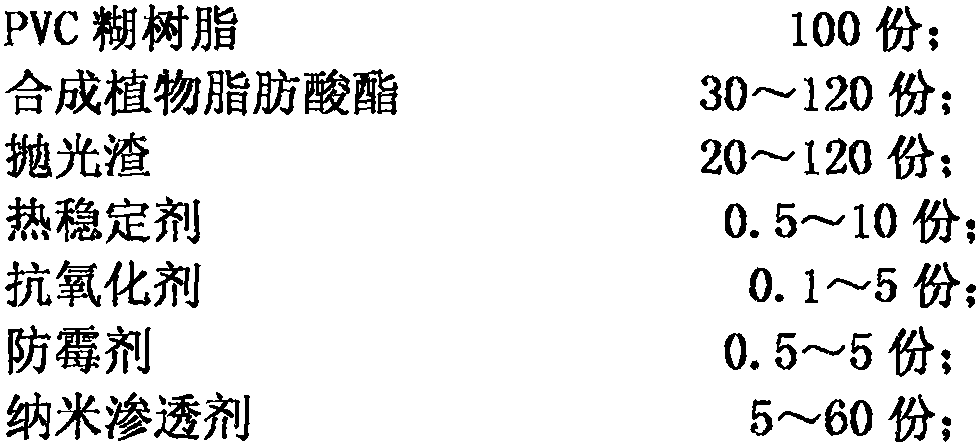

Method used

Image

Examples

Embodiment Construction

[0035] The present invention provides a nano-PVC flame-retardant waterproof tarpaulin and a preparation method thereof. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

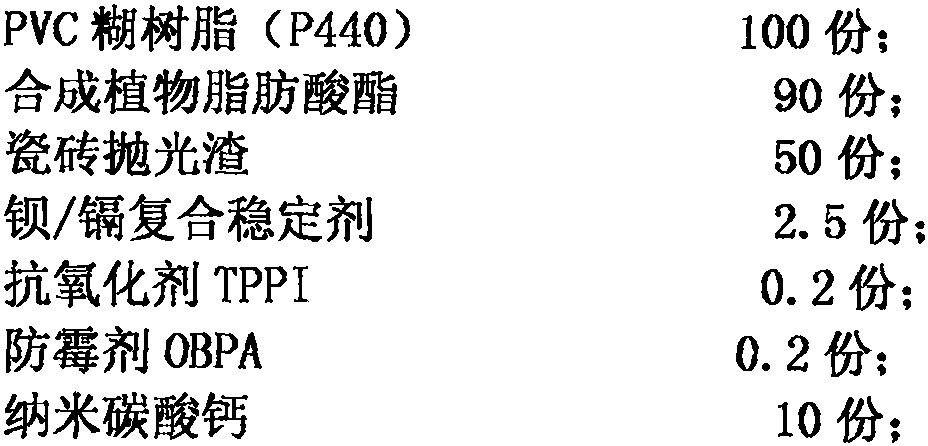

[0036] Implementation example one:

[0037] 1. Surface activation treatment of tile polishing slag;

[0038] Put the tile polishing slag into the high-speed mixer and stir at a high speed to make the temperature reach 100°C, stir at this temperature for 5 minutes, and dry the water; mix the coupling with a ratio of 1:2 (KH550: absolute ethanol) The solution is sprayed onto the surface of the tile polishing slag being stirred, stirred for another 10 minutes, and the solution on the surface of the polishing slag is dried to obtain a couplin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aggregation | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com