Paint for bathroom cabinet board material and preparation process thereof

A preparation process and technology for bathroom cabinets, which are applied in the direction of biocide-containing paints, coatings, antifouling / underwater coatings, etc. , to achieve the effect of improving water permeability, low thermal expansion coefficient, and improving pollution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

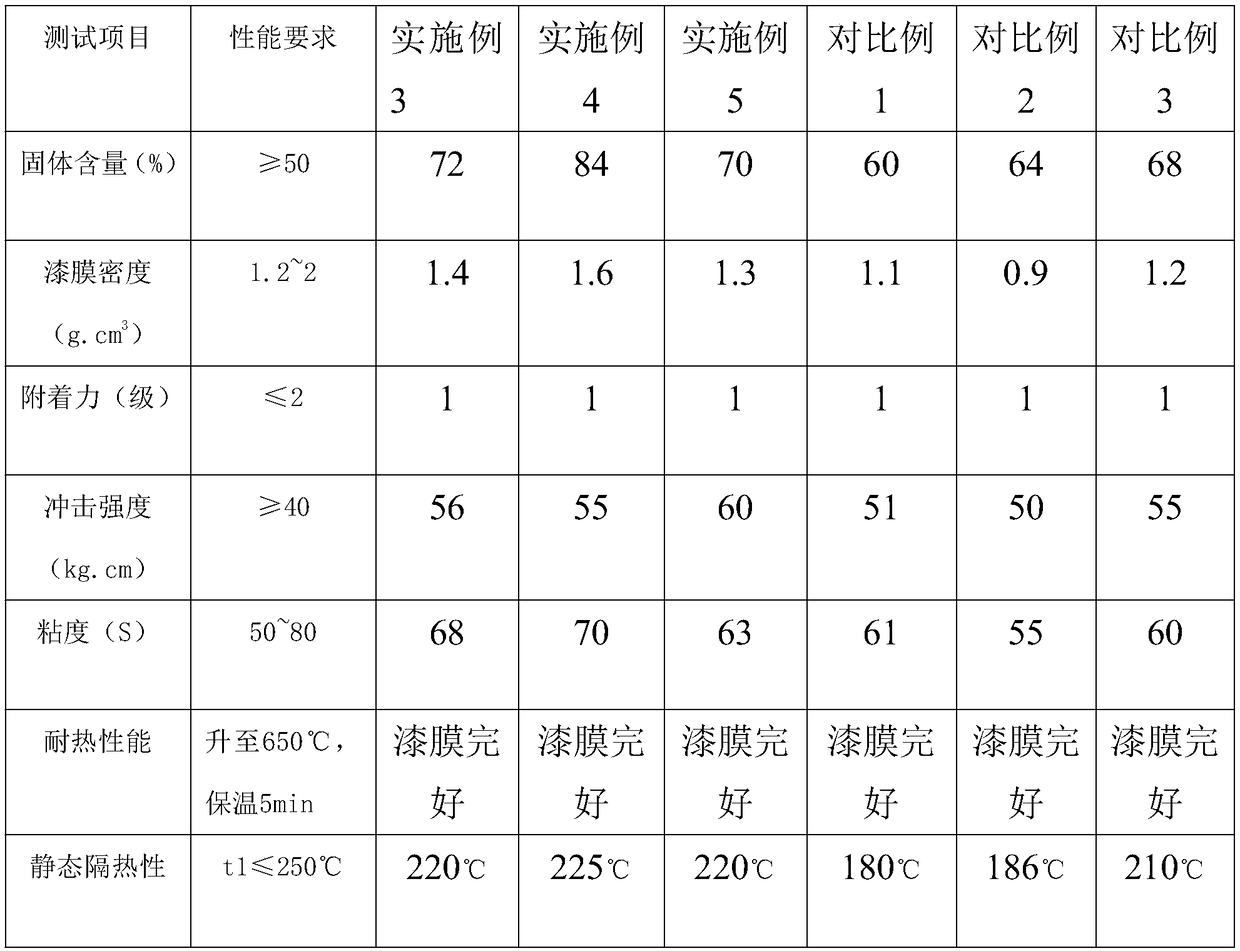

Examples

Embodiment 1

[0032] A paint for bathroom cabinet panels, comprising: 18kg of resin, 4kg of additive resin, 15kg of solvent, 4kg of auxiliary agent, and 40kg of filler; the resin is selected from amino resin; the additive resin is selected from acrylic modified epoxy resin, Acrylic resin, epoxy resin; solvent is selected from methyl isobutyl ketone; described filler is the mixture of lithopone, talcum powder, titanium dioxide, precipitated barium sulfate, bentonite, calcium carbonate; described auxiliary agent comprises graphite powder 13 parts, quartz 4 parts, kaolinite 18 parts, diamond powder 7 parts, mica powder 14 parts.

Embodiment 2

[0034] A paint for bathroom cabinet panels, comprising: 18kg of resin, 4kg of additive resin, 15kg of solvent, 4kg of auxiliary agent, and 40kg of filler; the resin is selected from amino resin; the additive resin is selected from acrylic modified epoxy resin, Acrylic resin, epoxy resin; solvent is selected from methyl isobutyl ketone; described filler is the mixture of lithopone, talcum powder, titanium dioxide, precipitated barium sulfate, bentonite, calcium carbonate; described auxiliary agent comprises graphite powder 13 parts, 4 parts of quartz, 18 parts of kaolinite, 7 parts of diamond powder, 14 parts of mica powder;

[0035] The additive is prepared by the following method: mixing graphite powder, quartz, mica powder, kaolinite, and diamond powder into a ball mill for grinding, passing through a 40-mesh sieve, adding deionized water and stirring for 20 minutes, and then filtering. Dry, crush again, and pass through a 100-mesh sieve to obtain the auxiliary agent.

Embodiment 3

[0037] A paint for bathroom cabinet panels, comprising: 18kg of resin, 4kg of additive resin, 15kg of solvent, 4kg of auxiliary agent, and 40kg of filler; the resin is selected from amino resin; the additive resin is selected from acrylic modified epoxy resin, Acrylic resin, epoxy resin; solvent is selected from methyl isobutyl ketone; described filler is the mixture of lithopone, talcum powder, titanium dioxide, precipitated barium sulfate, bentonite, calcium carbonate; described auxiliary agent comprises graphite powder 13 parts, 4 parts of quartz, 18 parts of kaolinite, 7 parts of diamond powder, 14 parts of mica powder;

[0038] The additive is prepared by the following method: mixing graphite powder, quartz, mica powder, kaolinite, and diamond powder into a ball mill for grinding, passing through a 40-mesh sieve, adding deionized water and stirring for 20 minutes, and then filtering. Dry, crush again, and pass through a 100-mesh sieve to obtain additives;

[0039] The pain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com