High-density low-water-permeability water-based outer wall polymer coating material and preparation method thereof

A low-permeability, polymer technology, applied in the field of coating properties, can solve the problems of improving the thermal conductivity of thermal insulation materials and reducing the thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

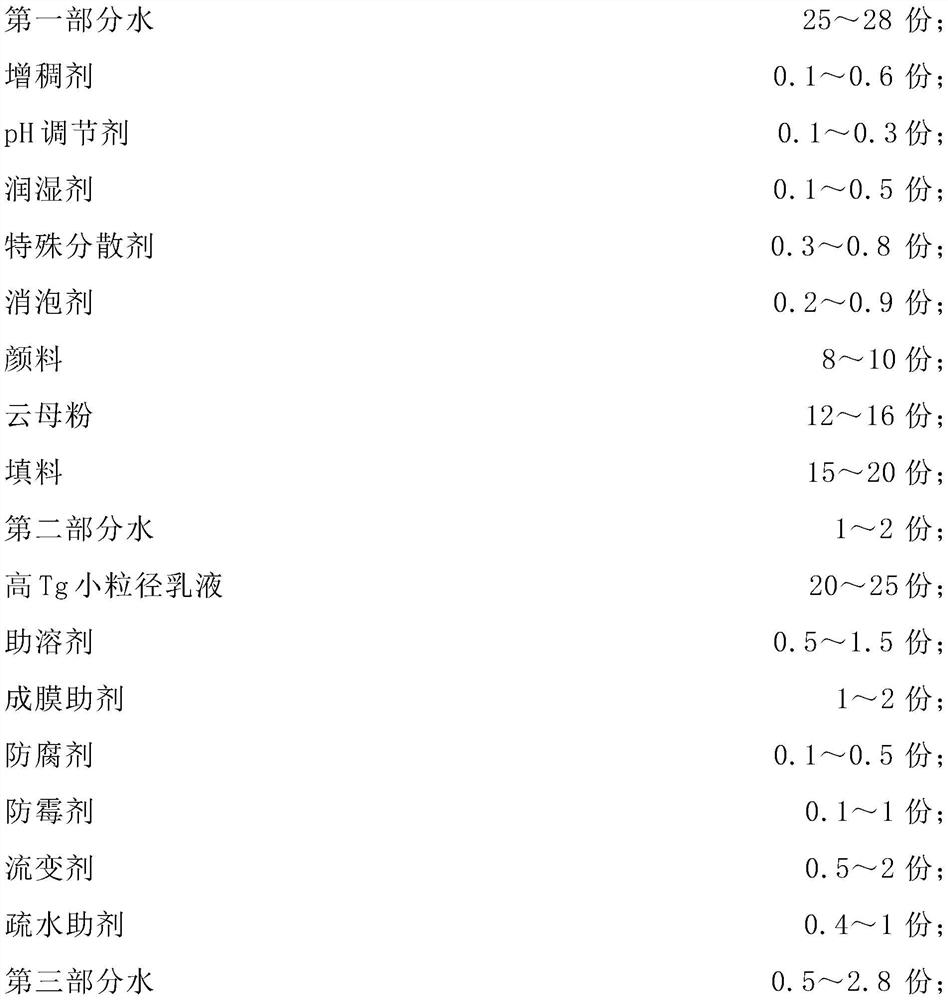

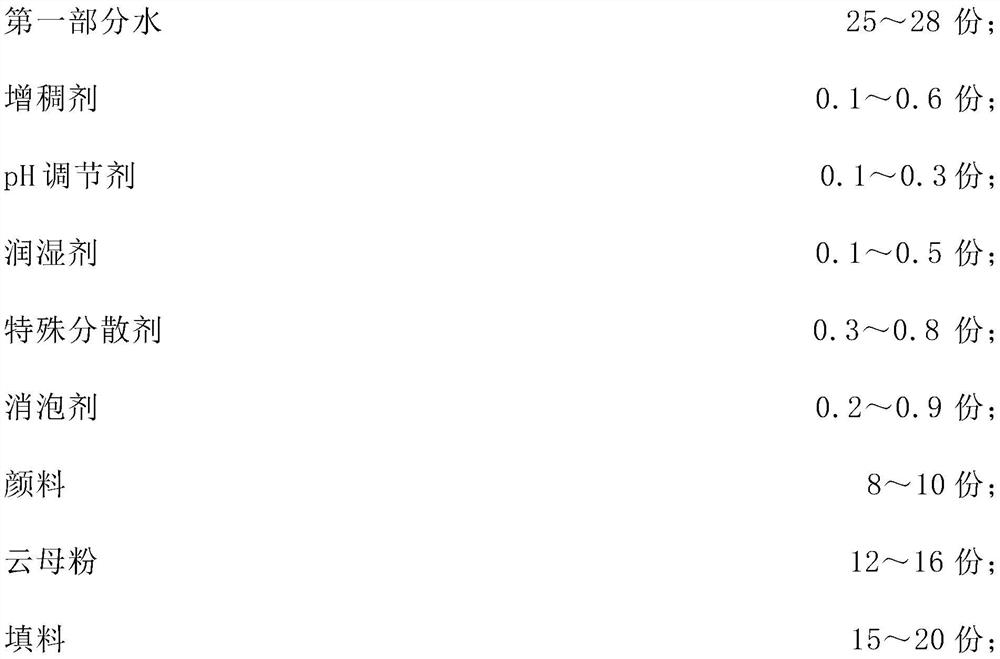

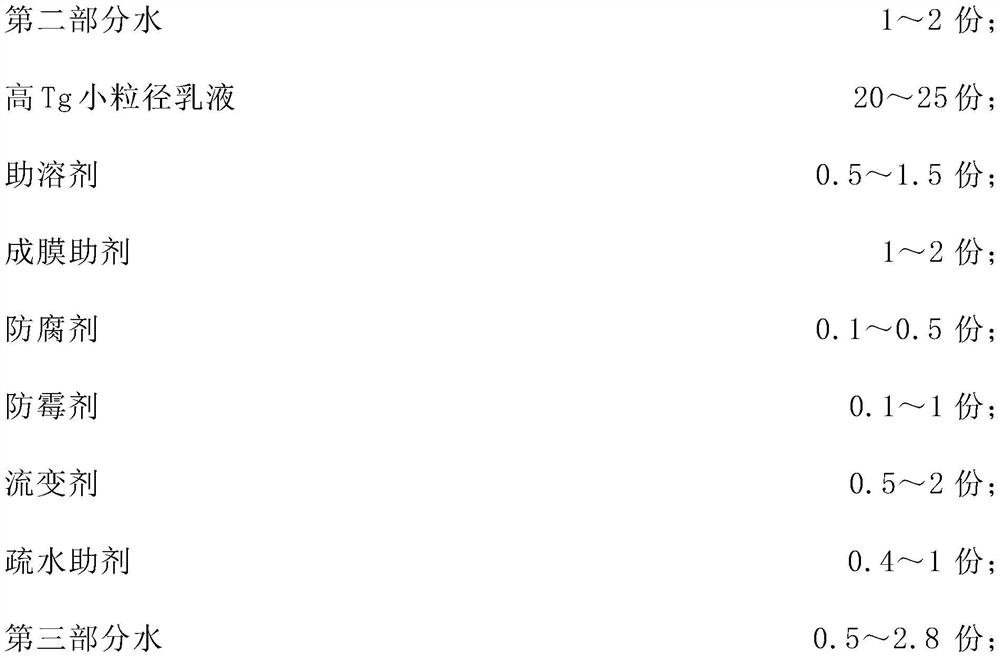

[0048]Example 1: A preparation method of a high-density and low-permeability water-based exterior wall polymer coating material

[0049] The preparation method of the high-density and low-permeable water-based exterior wall polymer finishing material of the present invention comprises the preparation of the first mixture and the second mixture:

[0050] a. wherein said first mixture is prepared as follows:

[0051] Use a dispersing disc for preparation, under stirring conditions, mix the first part of water, thickener, pH regulator, defoamer, special dispersant, wetting agent, mica powder and pigment, filler and the second part of water evenly;

[0052] b. wherein said second mixture is prepared as follows:

[0053] Use the same dispersing disc for preparation, add film-forming substances, co-solvents, film-forming aids, mildew inhibitors, preservatives, rheological agents, hydrophobic aids and the third part of water to the first mixture and mix well , and prepare the secon...

Embodiment 2

[0086] Put 28 parts by weight of water into the dispersing tank, stir with a dispersing disc, and control the speed at 200-300 rpm; add 0.34 parts by weight of hydroxyethyl cellulose thickener, 0.1 part by weight of organic amine pH regulator , 0.5 parts by weight of special dispersant, 0.1 parts by weight of non-ionic wetting agent, 0.4 parts by weight of a combination of silicone defoamer and mineral oil defoamer (the weight ratio of the two is 1:3), 8 parts by weight of rutile Type titanium dioxide, 14 parts by weight of mica powder, 7 parts by weight of calcined kaolin, 11 parts by weight of heavy calcium carbonate, add 1 part by weight of water, increase the speed to 1500-1600 rpm, and disperse at a high speed for 15 ± 1 minute to obtain the first mixture; then the rotating speed is reduced to 600-800 rpm, and then 23 parts by weight of high Tg small particle size emulsion, 1.5 parts by weight of glycol co-solvent, 1.7 parts by weight of alcohol ester film-forming aid, 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com