A kind of urea grease/biuret-based liquid potassium zinc foaming stabilizer for PVC and preparation method thereof

A foaming stabilizer and biuret technology, which is applied in the field of PVC urea grease/biuret-based liquid potassium-zinc-catalyzed foaming stabilizer and its preparation field, achieves smooth and smooth surface of the product, broad market value and good fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

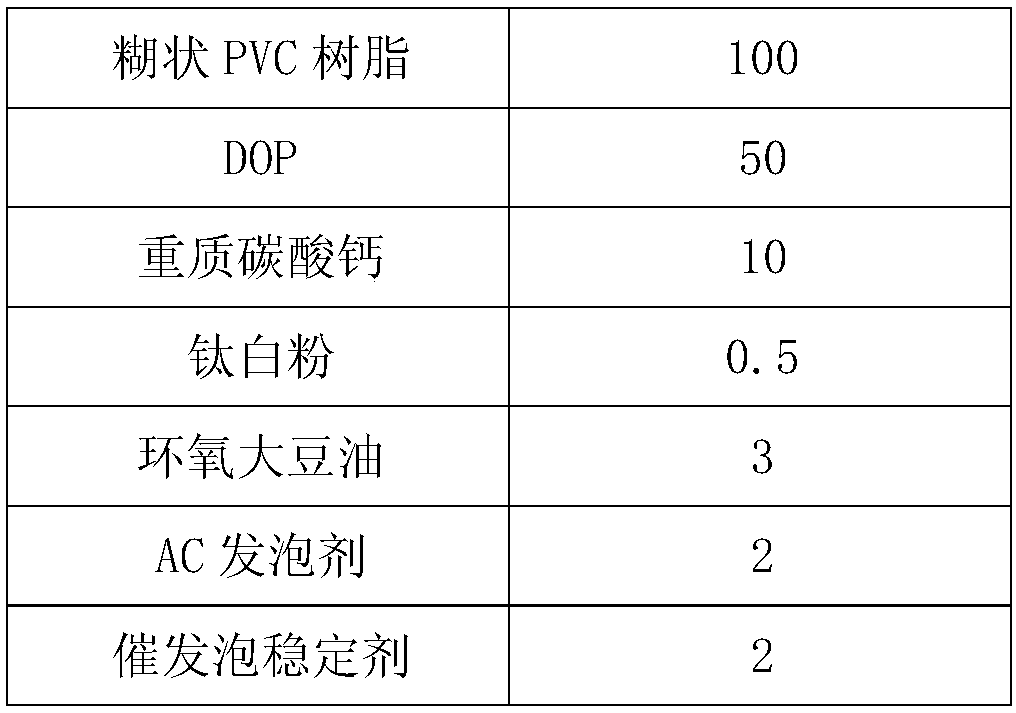

Examples

Embodiment 1

[0043] (1) The first step, the raw material components used are: diethylene glycol 325kg, oleic acid 337kg, isooctanoic acid 165kg, urea 302kg; Used catalyst is sodium carbonate, accounts for 3% of aforementioned raw material total amount. The reaction was maintained at a pressure of 0.4-0.6 MPa, stirred and heated up to 140° C., and the reaction state was maintained for 2 hours. Cool after the reaction, adjust the pH value to 7, and obtain a urea ester / biuret-based emulsion.

[0044] (2) In the second step, the raw material components used are: diethylene glycol 100kg, diethylene glycol monobutyl ether 62kg, isooctanoic acid 355kg, oleic acid 49kg, potassium hydroxide 22kg, zinc oxide 110kg. The reaction was maintained at normal pressure, stirred and heated to 80°C, kept for 1 hour, and then heated to 130°C for negative pressure dehydration. Cool after the reaction to obtain a potassium salt / zinc salt solution.

[0045](3) In the third step, the raw material components used...

Embodiment 2

[0047] The raw material components used for the compounding of the stabilizer are: 221 kg of the urea grease / biuret-based emulsion obtained in the first step of Example 1, 272 kg of the potassium salt / zinc salt solution obtained in the second step of Example 1, adding dibenzoylmethane 24kg, diphosphite bisphenol A four C 12-15 Ester 33kg. Mix and stir under normal pressure, and raise the temperature to 100°C. After the solution is transparent and clear, it can cool down to 60°C, and filter to obtain a light yellow transparent liquid, which is urea grease / biuret group liquid potassium zinc for PVC foaming stability agent.

Embodiment 3

[0049] (1) The first step, the raw material components used are: dearomatized hydrocarbon solvent oil D100, 328kg, oleic acid 300kg, isooctanoic acid 114kg, urea 188kg, the catalyst used is potassium dihydrogen phosphate and accounts for 5% of the aforementioned raw material total amount %. The reaction was maintained at a pressure of 0.5-0.8 MPa, stirred and heated up to 140° C., and the reaction state was maintained for 2 hours. Cool after the reaction, adjust the pH value to 7, and obtain a urea ester / biuret-based emulsion.

[0050] (2) In the second step, the raw material components used are: 55kg of diethylene glycol monobutyl ether, 370kg of isooctanoic acid, 50kg of oleic acid, and 125kg of zinc oxide. The reaction was maintained at normal pressure and heated to 90 °C.

[0051] (3) In the third step, in the solution of the reaction to 90° C. in the second step, the raw material components that are added successively are 310 kg of urea fat / biuret-based emulsion obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com