Copper-plating-free CO2 gas shielded welding wire coating and coated welding wire adopting same

A gas-shielded welding wire, copper-free technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of different, affecting the performance of welding wire, etc., to improve adhesion, solve the problem of coating peeling off and blocking the contact tip, The effect of low coating peeling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

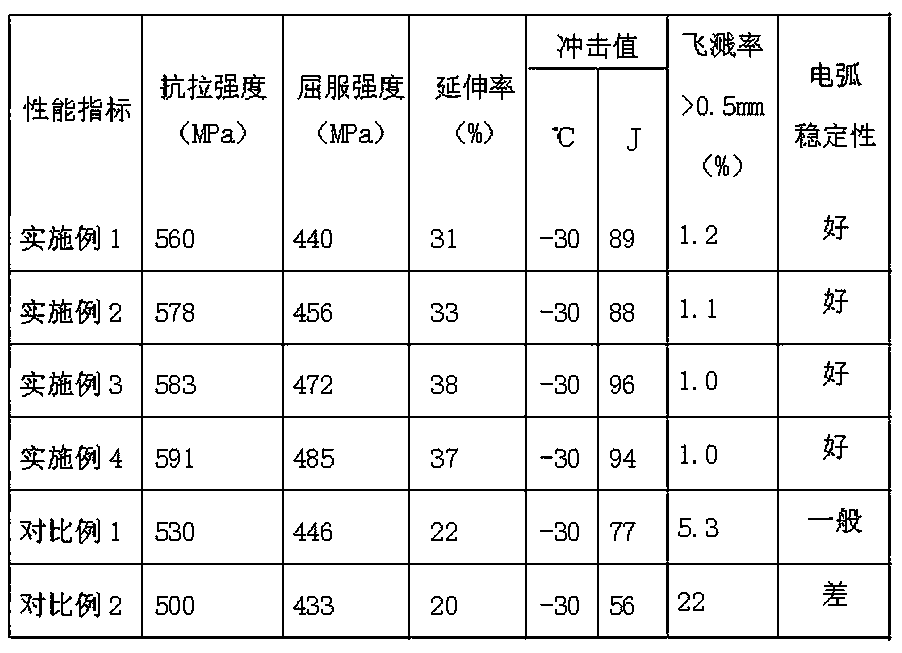

Embodiment 1

[0032] According to the mass ratio, with 80% palm oil as the coating carrier, add 5% lithium carbonate, 5% sodium carbonate, 5% calcium carbonate, 5% cesium carbonate respectively and stir to form a coating liquid, Dip the pretreated wire matrix into it and stay for 3s.

Embodiment 2

[0034] According to the mass ratio, take 85% palm oil as the coating carrier, add 2% lithium carbonate, 4% sodium carbonate, 7% calcium carbonate, 2% cesium carbonate respectively and stir to form a coating liquid, Dip the pretreated wire matrix into it and stay for 2s.

Embodiment 3

[0036] According to the mass ratio, 70% palm oil is used as the coating carrier, and 2% lithium carbonate, 4% sodium carbonate, 7% calcium carbonate, 2% cesium carbonate and 5% sodium chloride are respectively added therein. 10% oxidized calcium wax and stirred evenly to form a coating liquid, the pretreated wire substrate was subjected to wire surface coating treatment at 80°C, and the wire was immersed in it and stayed for 3s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com