Calcium-zinc stabilizer and application thereof in SPC floor base material production

A technology of calcium-zinc stabilizer and calcium stearate, which is applied in the field of calcium-zinc stabilizer and its application in the production of SPC floor substrates, can solve the problems of poor plasticizing ability of calcium-zinc stabilizer and achieve excellent thermal stability The effect of high resistance, great lubrication and long thermal stability time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

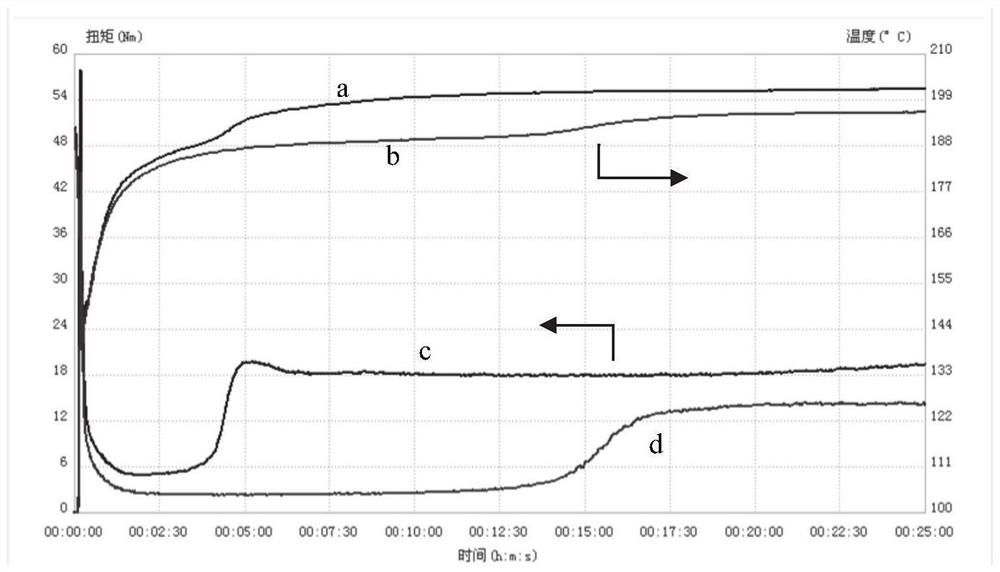

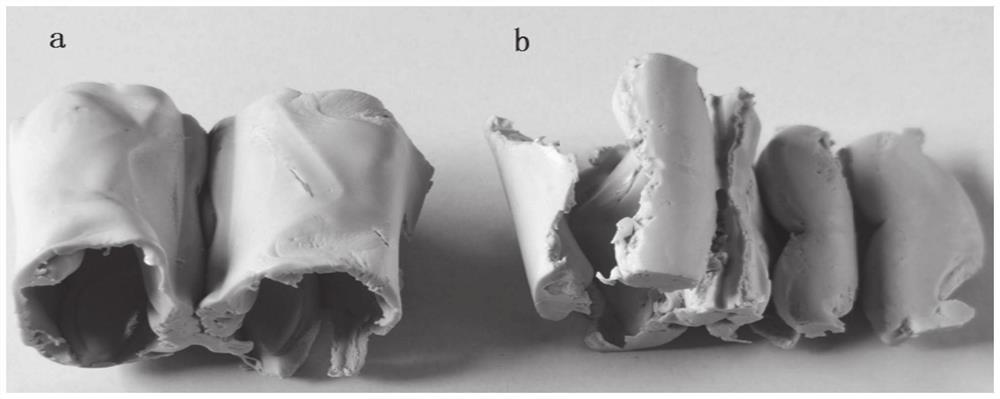

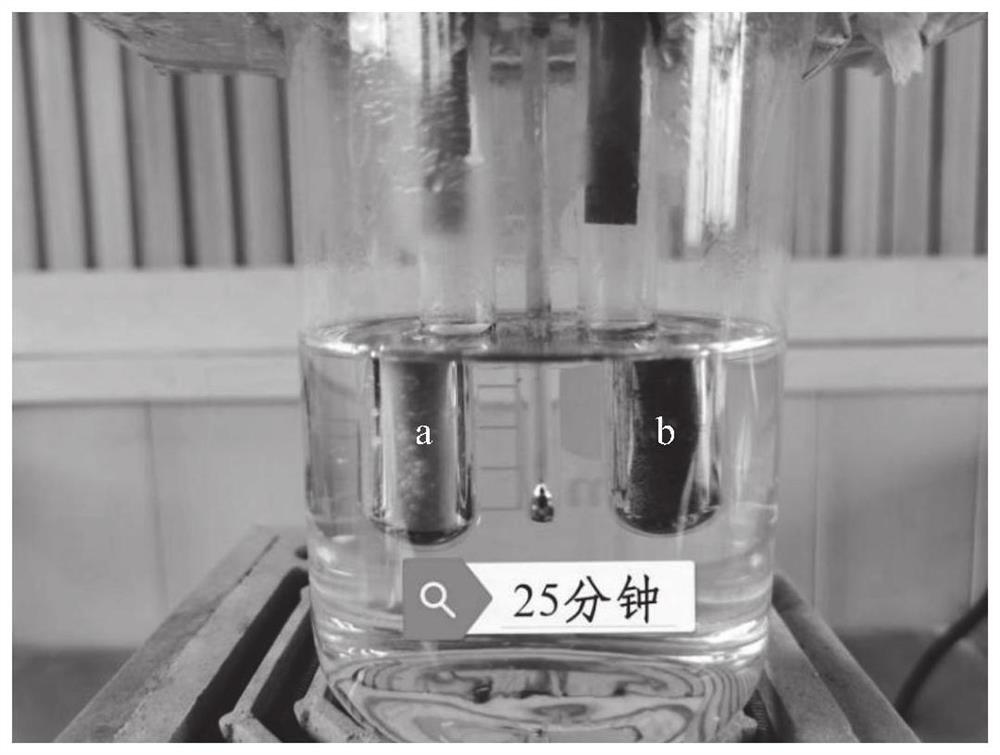

Image

Examples

preparation example Construction

[0031] The preferred preparation method of the present invention, the steps are as follows:

[0032] 1. Turn on the steam, preheat the reactor to 70-75°C, and keep it for 20-40 minutes to make the temperature of the reactor even.

[0033] 2. Turn on the mixer, slowly add stearic acid, stir and slowly dissolve, heat to 115-120°C to completely melt, add zinc oxide, stir for 20-40 minutes to complete the reaction.

[0034] 3. Heat to 120-130°C (to ensure that calcium stearate melts), add calcium stearate, hydrotalcite, monoglyceride, polyethylene wax, pentaerythritol, light calcium carbonate one after another, and stir for 20-40 minutes (keep 120 ~130°C).

[0035] 4. Add antifungal agent and anti-ultraviolet absorber and stir (keep the temperature at 120-130°C) for 10-20 minutes.

[0036] 5. Discharge the material, pass through the double-roller cooling tablet press, and press the tablet into shape.

Embodiment approach

[0037] The third embodiment of the present invention provides an application of the above-mentioned calcium-zinc stabilizer in the production of SPC floor substrates.

[0038] The fourth embodiment of the present invention provides a kind of SPC floor base material. The raw materials include, in terms of mass parts, 50 parts of PVC, 150-175 parts of calcium powder, 30-50 parts of recycled materials, 4-5 parts of stabilizer, 1.7-2.0 parts of lubricant, 2-3.5 parts of processing aid; wherein, the stabilizer is the above-mentioned calcium-zinc stabilizer.

[0039] In some examples of this embodiment, the lubricant is an internal lubricant and an external lubricant. The internal lubricant includes G60 and the like. The external lubricant includes PE wax and the like. The preferred mass ratio of the internal lubricant to the external lubricant is 0.7-0.8:1.0-1.2.

[0040] In some examples of this embodiment, the processing aids include plasticizers and impact modifiers. It is p...

Embodiment 1

[0043] The preparation method of calcium-zinc stabilizer, the steps are as follows:

[0044] 1. Turn on the steam, preheat the reactor to 70°C, and keep it for 30 minutes to make the temperature of the reactor even.

[0045] 2. Turn on the mixer, slowly add 70 parts by mass of stearic acid, stir and dissolve slowly, heat to 115°C to completely melt, add 6 parts by mass of nano-zinc oxide, and stir for 30 minutes to complete the reaction.

[0046] 3, successively add 4 mass parts calcium stearate, 3 mass parts hydrotalcite, 8 mass parts monoglyceride, 7 mass parts polyethylene wax, 3 mass parts pentaerythritol, 6 mass parts light calcium carbonate, stir 30 minutes (keep 125°C).

[0047] 4. Add 1 mass part of antifungal agent and 3 mass parts of anti-ultraviolet absorbing agent and stir for 15 minutes.

[0048] 5. Discharge the material, pass through a double-roller cooling tablet press, and press into tablets to obtain a calcium-zinc stabilizer.

[0049] The calcium-zinc sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com