A liquid barium/zinc transparent composite heat stabilizer for pvc

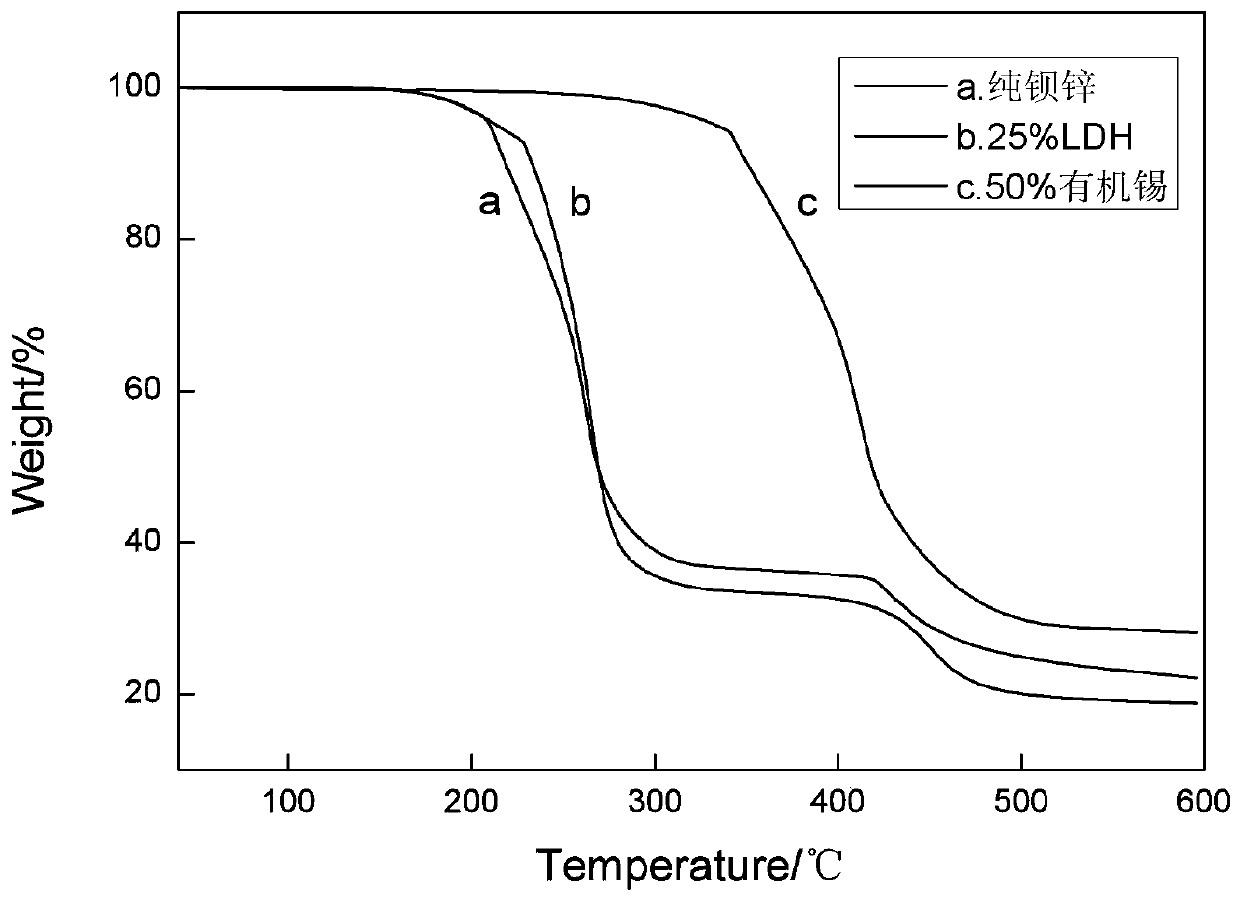

A technology of composite heat stabilizer and auxiliary heat stabilizer, which is applied in the field of transparent barium/zinc composite heat stabilizer for PVC and its preparation, and heat stabilizer for PVC, which can solve the problems of low stabilization efficiency, expensive transparency, toxic price, etc. problems, to achieve the effects of improved aging resistance, prolonged thermal stability time, and improved transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Barium isooctanoate and zinc isooctanoate were uniformly mixed in a high-speed mixer according to the ratio in Table 1 to prepare barium isooctanoate / zinc composite heat stabilizer.

[0026] Table 1 barium isooctanoate / zinc composite heat stabilizer formula

[0027]

[0028]

[0029] Mix 4 parts of the prepared composite heat stabilizer, 40 parts of DOP, and 100 parts of PVC evenly, and plasticize it on a double-roll rubber mixer with a roll temperature of 160 ° C and a roll distance of 1.5 mm, and then pelletize it into a test tube. In an oil bath at ℃, the static thermal stability of the compound was measured according to the national standard GB / T2917.1-2002 Congo red method, and the results are shown in Table 2.

[0030] Table 2 Static thermal stability test of different compound ratios of barium isooctanoate / zinc isooctanoate

[0031]

[0032] The data in Table 2 shows that the barium / zinc compound has a certain synergistic effect, and the thermal stabili...

example 2

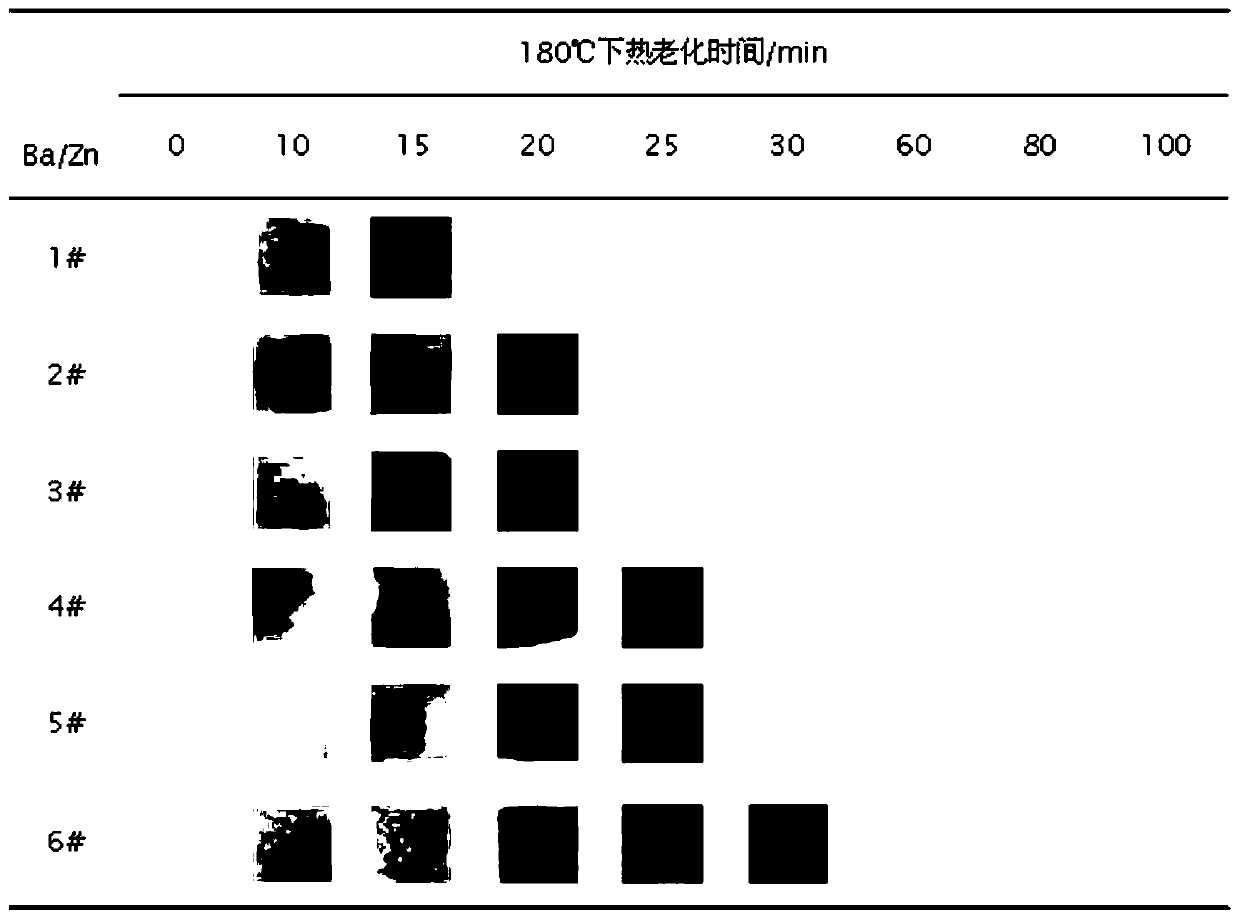

[0041] Mix barium isooctanoate, zinc isooctanoate and hydrotalcite in a high-speed mixer according to the ratio in Table 5 to prepare barium isooctanoate / zinc composite heat stabilizer.

[0042] Table 5 barium isooctanoate / zinc / hydrotalcite composite heat stabilizer formula

[0043]

[0044] Mix 4 parts of the prepared composite heat stabilizer, 40 parts of DOP, and 100 parts of PVC evenly, and plasticize it on a double-roll rubber mixer with a roll temperature of 160 ° C and a roll distance of 1.5 mm, and then pelletize it into a test tube. In an oil bath at ℃, the static thermal stability of the compound was measured according to the national standard GB / T2917.1-2002 Congo red method, and the results are shown in Table 6.

[0045] The static heat stability test of table 6 barium isooctanoate / zinc / hydrotalcite composite heat stabilizer

[0046]

[0047] The data in Table 6 shows that the addition of hydrotalcite can significantly improve the static thermal stability of...

example 3

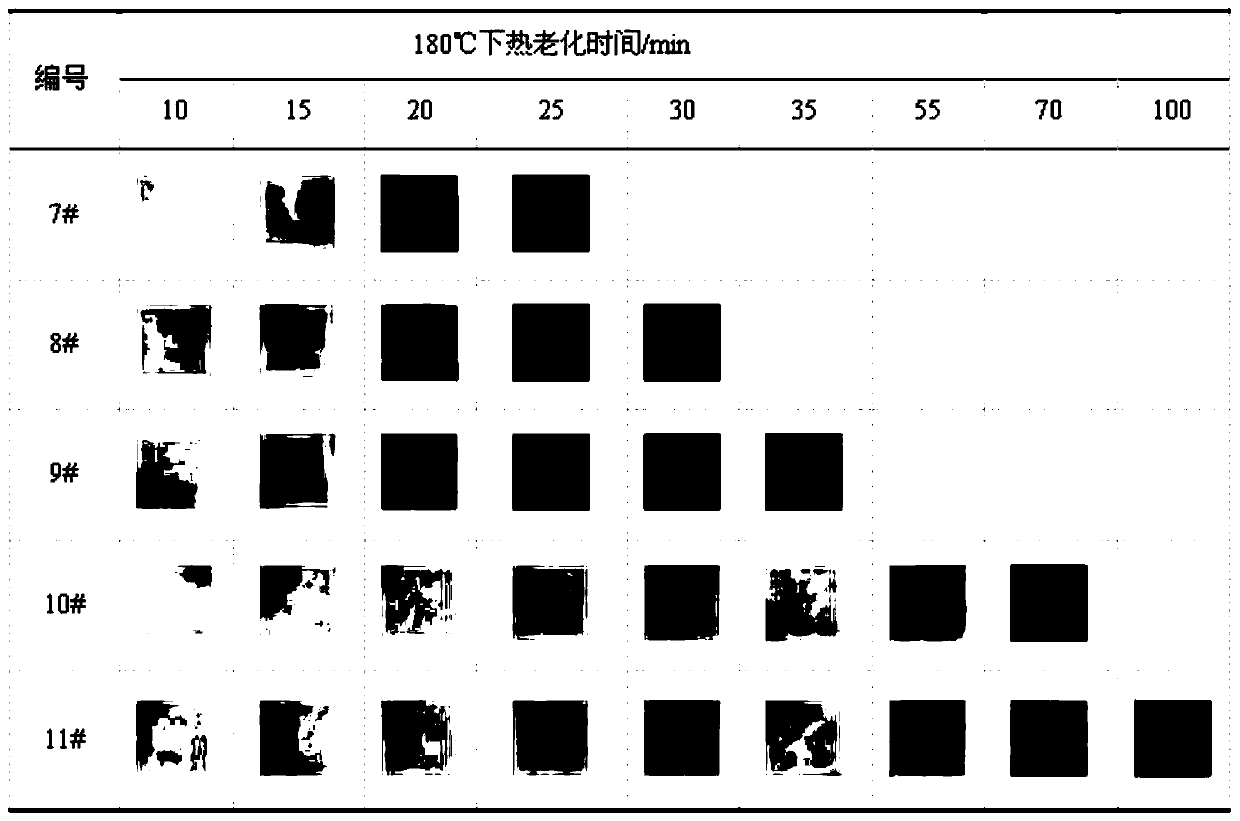

[0055] Barium isooctanoate, zinc isooctanoate and organotin mercaptide were uniformly mixed in a high-speed mixer according to the ratio in Table 9 to prepare a barium isooctanoate / zinc composite heat stabilizer.

[0056]Table 9 barium isooctanoate / zinc / thiol organotin composite heat stabilizer formula

[0057]

[0058] Mix 4 parts of the prepared composite heat stabilizer, 40 parts of DOP, and 100 parts of PVC evenly, and plasticize it on a double-roll rubber mixer with a roll temperature of 160 ° C and a roll distance of 1.5 mm, and then pelletize it into a test tube. In an oil bath at ℃, the static thermal stability of the compound was measured according to the national standard GB / T2917.1-2002 Congo red method, and the results are shown in Table 10.

[0059] Table 10 Static thermal stability test of barium isooctanoate / zinc / mercaptan organotin composite heat stabilizer

[0060]

[0061] The data in Table 10 shows that the addition of mercaptan organotin can signific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com