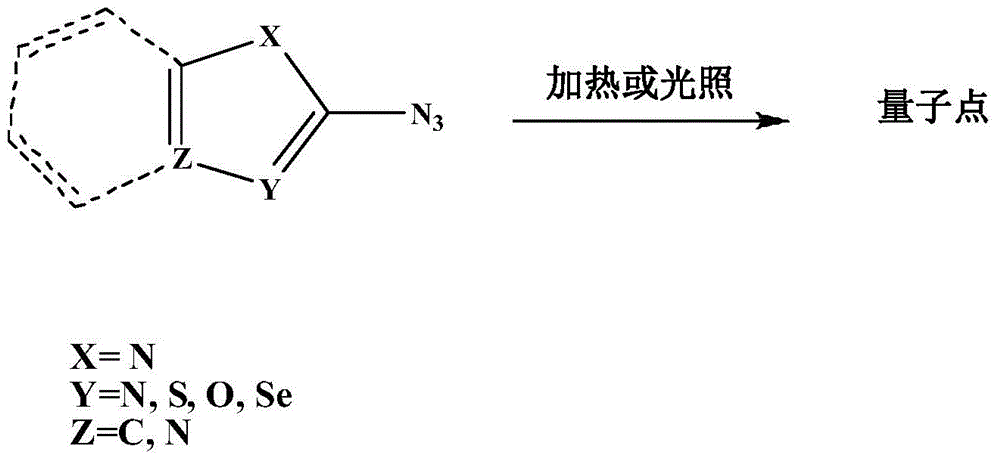

Preparation method of fluorescent nitrogen-enriched quantum dots as well as products and application of quantum dots

A quantum dot and fluorescence technology, which is applied in the preparation of fluorescent nitrogen-rich quantum dots and its products and applications, can solve the problems of low quantum efficiency of carbon dots, complex components, difficult to repeat the reaction, etc., to achieve biological safety and biophase Good capacitance, excellent fluorescence properties, and high quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Synthesis of reaction materials

[0052] Synthesis of 2-azidoimidazole

[0053] 2-azidoimidazole sulfate (3.30g, 25.0mmol) was dissolved in HCl aqueous solution (5.0mol / L, 20mL), cooled to 0℃ in an ice water bath, and then NaNO was added dropwise 2 (1.73g, 25.1mmol) aqueous solution and NaN 3 (1.63g, 25.1mmol) in water. The mixed solution was slowly raised from 0°C to room temperature, and then stirred and reacted at room temperature for 20 hours. Stop the reaction and use solid NaHCO 3 After adjusting the pH to neutral, extract with ethyl acetate (3×50mL), anhydrous Na 2 SO 4 Dry, filter, and spin-dry the filtrate to obtain a yellow powder. The obtained yellow powder was purified by silica gel column (developing solvent petroleum ether: ethyl acetate = 1:1), and finally 2.31 g of yellow crystal solid was obtained with a yield of 84.7%. 1 HNMR(DMSO)δ[ppm]6.88(s, 1H); 13 CNMR (DMSO) δ [ppm] 139.91, 127.33, 116.24. FTIR(cm -1 )-N 3 2132cm -1 .

[0054] Synthesis of ...

Embodiment 2

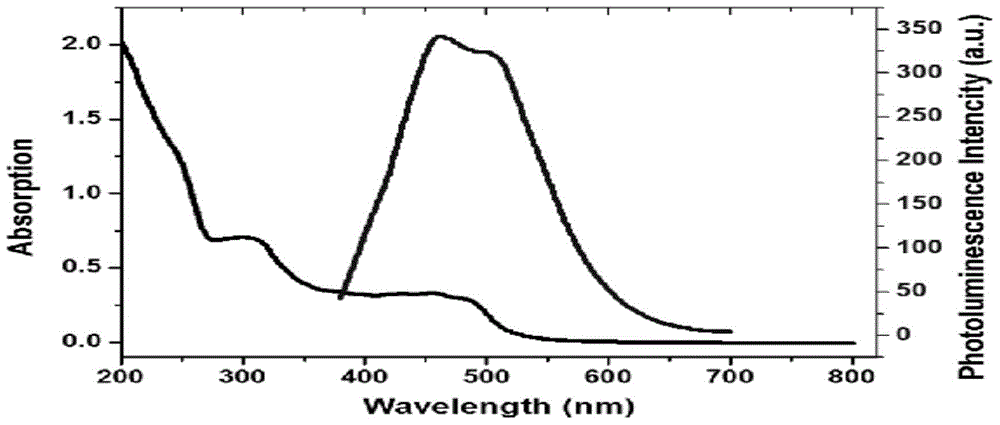

[0061] Example 2 Preparation of fluorescent nitrogen-rich quantum dots

[0062] Method 1: A methanol solution (75ml) of 2-azidoimidazole (0.360g) was stirred at 70°C for 24 hours. After the reaction, the methanol was removed by rotary evaporation under reduced pressure and dried. The residue was washed with ethyl acetate for 3 to 4 times until the reaction material (2-azidoimidazole) disappeared, and then dried; the dried product was re-dispersed with water, and the aqueous solution was passed through 0.8μm , 0.45μm and 0.22μm filter membranes, the filtrate was vacuum freeze-dried to obtain 0.120g red-brown solid, the crude product yield was 33%. The obtained crude nitrogen-rich quantum dots are further passed through Sephadex G-25 chromatographic column (the inner diameter of the column is 1.5cm, the height of the gel column is 20-30cm, and the amount of sample <100mg, the flow rate is about 0.2ml / min) purification, the developing solvent is water: methanol = 95:5, according to ...

Embodiment 3

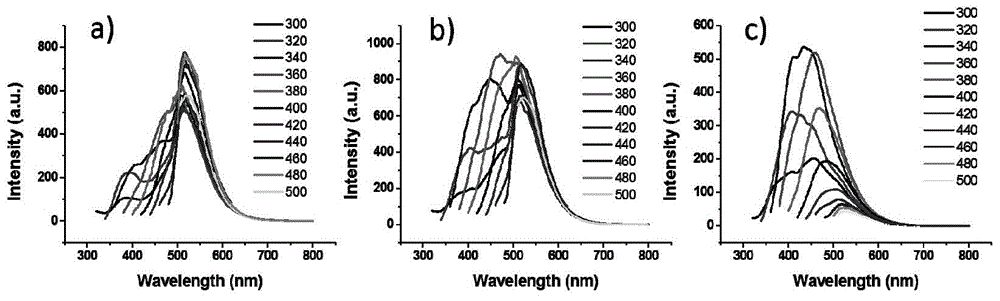

[0067] Example 3 Preparation of fluorescent nitrogen-rich quantum dots under different reaction temperature conditions

[0068] By changing the reaction temperature of carbon quantum dots from 2-azidoimidazole, nitrogen-rich quantum dots with different fluorescence properties can also be obtained.

[0069] After reacting the methanol solution of 2-azidoimidazole at 50℃ for 24, the obtained crude nitrogen-rich quantum dots have similar spectroscopic properties to N-dot3, and the emission peak is fixed at about 515nm, such as figure 2 (a). When the reaction temperature is changed to 100°C and other conditions remain unchanged, the obtained crude nitrogen-enriched quantum dots have similar spectral properties to N-dot1. With the change of excitation wavelength, the emission peak changes, such as figure 2 (c). Therefore, by controlling the reaction temperature of 2-azidoimidazole to produce carbon quantum dots, the progress of the reaction and the fluorescence properties of the obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com