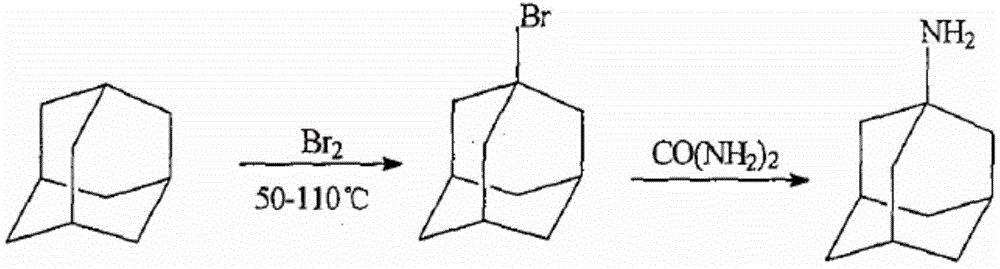

Process for high-yield preparation of amantadine hydrochloride

An amantadine hydrochloride, high-yield technology, applied in the field of high-yield preparation of amantadine hydrochloride, can solve the problems of difficulty in recovery, high price, strong corrosiveness, etc., achieves improved conversion rate and yield, and increased units Yield, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] A kind of high yield prepares the technique of amantadine hydrochloride, comprises the following steps:

[0048] (1) Preparation of 1-acetylaminoadamantane;

[0049] ① Prepare the raw materials;

[0050] ②Pre-cool the first reaction kettle with a specification of 50L in advance, gradually add 25L (47.5kg) of fuming sulfuric acid, stir for 10 minutes, and add 7.5kg of adamantane in batches at -5°C. Can not exceed 0 ℃, continue to stir for half an hour after adding;

[0051] ③At -5°C, add 6.5L (5.2kg) of acetonitrile dropwise. During the dropping process, the temperature should not exceed 0°C; keep stirring for half an hour after dropping, slowly raise the temperature to 35°C (room temperature), and keep the temperature for 3 hours;

[0052] ④ Slowly add 2.5kg of adamantane when the reaction solution becomes clear; keep the temperature from rising during the addition, and stir for another 3 hours after addition;

[0053] More was added and the temperature was raised to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com