Method for continuously catalyzing and synthesizing ATS-7 by immobilized enzyme fluidization bed

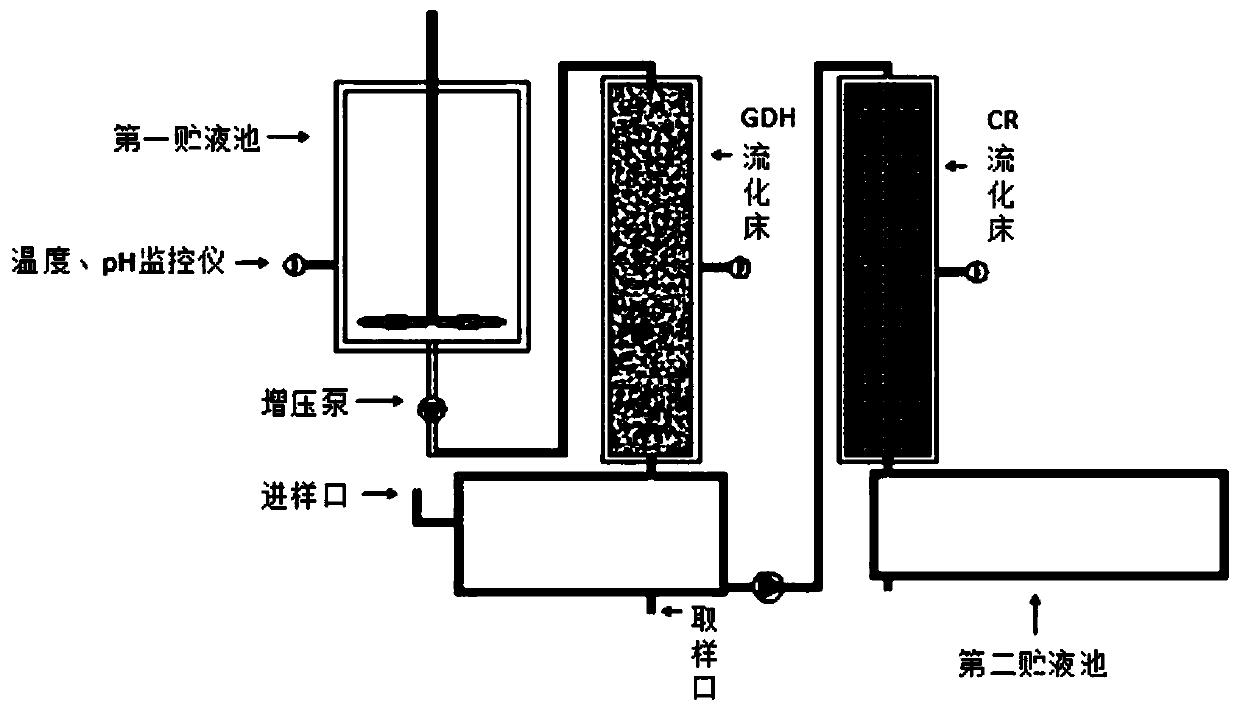

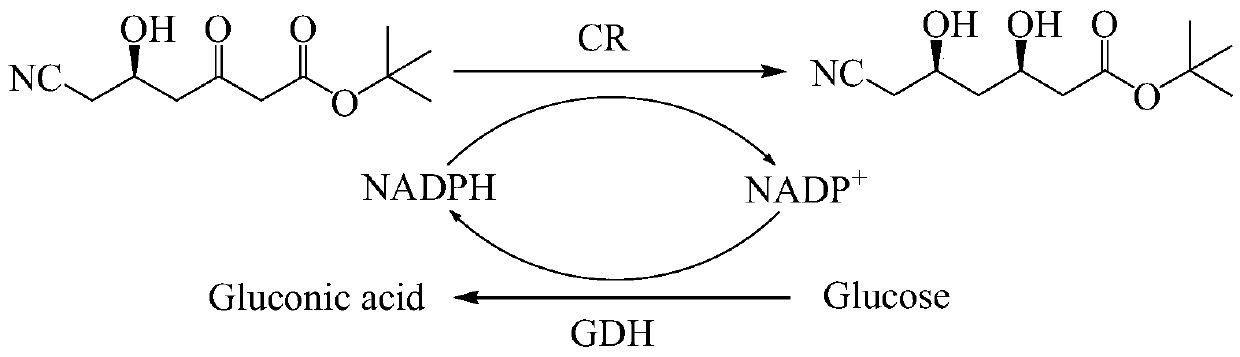

An immobilized enzyme fluidized bed, ATS-7 technology, applied in the field of medicine and chemical industry, can solve the problems of low yield and low utilization rate of enzymes, and achieve the effect of simplifying purification steps, facilitating industrialization, and facilitating separation from products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for continuously catalytically synthesizing ATS-7 in an immobilized enzyme fluidized bed, comprising the steps of:

[0029] 1) Prepare 0.2 mol / L phosphate buffer solution (pH=6.5-7.8) with dipotassium hydrogen phosphate and potassium dihydrogen phosphate, and set aside.

[0030] 2) Add 15g of macroporous silica gel to 35mL, 0.2mol / L phosphate buffer solution and soak for 12h; after soaking, wash the macroporous silica gel: remove the supernatant, add 35mL, 0.2mol / L The fresh phosphate buffer solution, shaking for 3 minutes, standing for 2 minutes, replacing the buffer solution, and repeating the steps of washing the macroporous silica gel 4 times.

[0031] 3) Place the treated macroporous silica gel in 8.5g GDH solution (1.7g GDH is diluted with phosphate buffer solution of 0.2mol / L, pH=7.0, the mass concentration of GDH solution is 20%), and at 25°C, Stir and adsorb at a speed of 200r / min for 55min to obtain immobilized GDH, and the fixation rate of GDH is 60...

Embodiment 2

[0039] A method for continuously catalytically synthesizing ATS-7 in an immobilized enzyme fluidized bed, comprising the steps of:

[0040] 1) Prepare 0.2 mol / L phosphate buffer solution (pH=6.5-7.8) with dipotassium hydrogen phosphate and potassium dihydrogen phosphate, and set aside.

[0041] 2) Add 15g of macroporous silica gel to 35mL, 0.2mol / L phosphate buffer solution and soak for 12h; after soaking, wash the macroporous silica gel: remove the supernatant, add 35mL, 0.2mol / L The fresh phosphate buffer solution, shaking for 3 minutes, standing for 2 minutes, replacing the buffer solution, and repeating the steps of washing the macroporous silica gel 4 times.

[0042] 3) Place the treated macroporous silica gel in 8.5g GDH solution (1.7g GDH is diluted with 0.2mol / L, pH=7.0 phosphate buffer solution, the mass concentration of GDH solution is 16.7%), and at 25°C, Stir and adsorb at a speed of 200r / min for 55min to obtain immobilized GDH, and the fixation rate of GDH is 60%...

Embodiment 3

[0050] A method for continuously catalytically synthesizing ATS-7 in an immobilized enzyme fluidized bed, comprising the steps of:

[0051] 1) Prepare 0.2 mol / L phosphate buffer solution (pH=6.5-7.8) with dipotassium hydrogen phosphate and potassium dihydrogen phosphate, and set aside.

[0052] 2) Add 15g of macroporous silica gel into 35mL, 0.2mol / L phosphate buffer solution and soak for 12h; after soaking, wash the macroporous silica gel: remove the supernatant, add 15g of soaked macroporous silica gel / L of fresh phosphate buffer solution, shake for 3 minutes, let stand for 2 minutes, replace the buffer, and repeat the steps of washing the silica gel 4 times.

[0053] 3) Place the treated macroporous silica gel in 8.5g GDH solution (1.7g GDH is diluted with 0.2mol / L phosphate buffer solution, the mass concentration of GDH solution is 25%), and at 25°C, at 200r / min The mixture was stirred and adsorbed at a rotating speed for 55 minutes to obtain immobilized GDH, and the imm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com