Method for preparing trichlorosilane and dichlorosilane by hydrogenating silicon tetrachloride through microwave plasma

A hydrogenated silicon tetrachloride production, microwave plasma technology, applied in the direction of silicon halides, halosilanes, etc., can solve the problems of high equipment requirements, high energy consumption, low plasma ionization degree, etc., to achieve a high conversion rate, The effect of high ion density and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

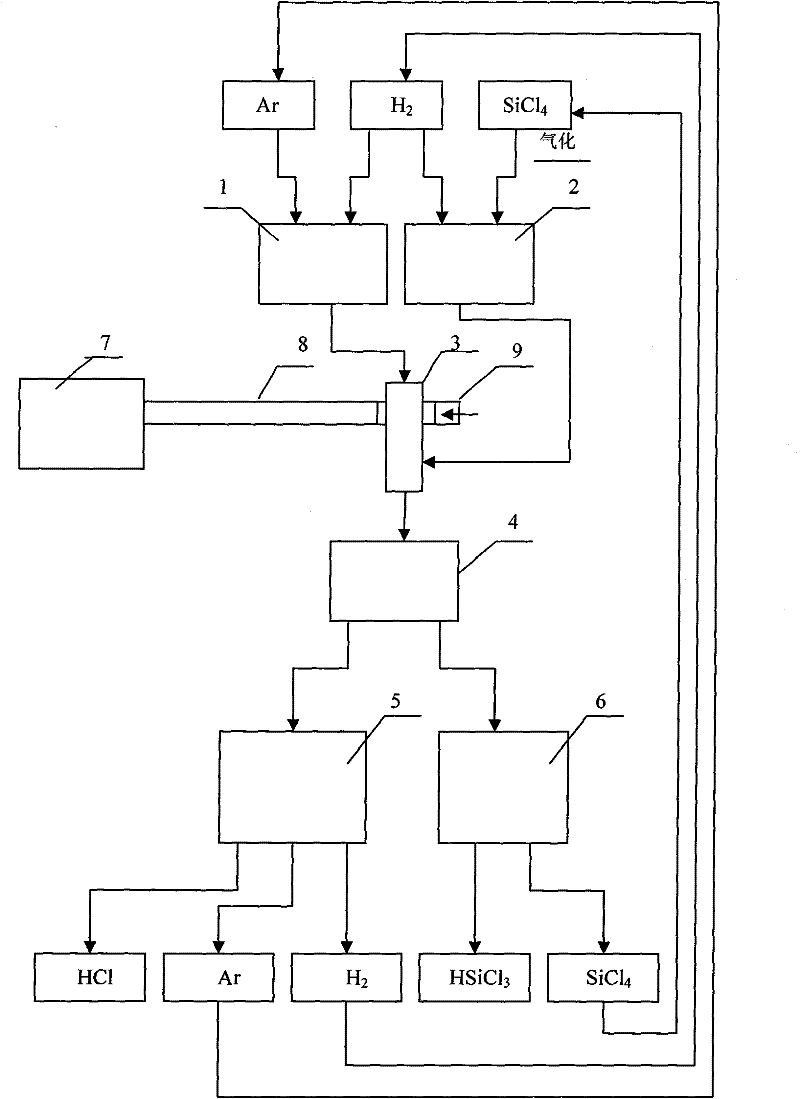

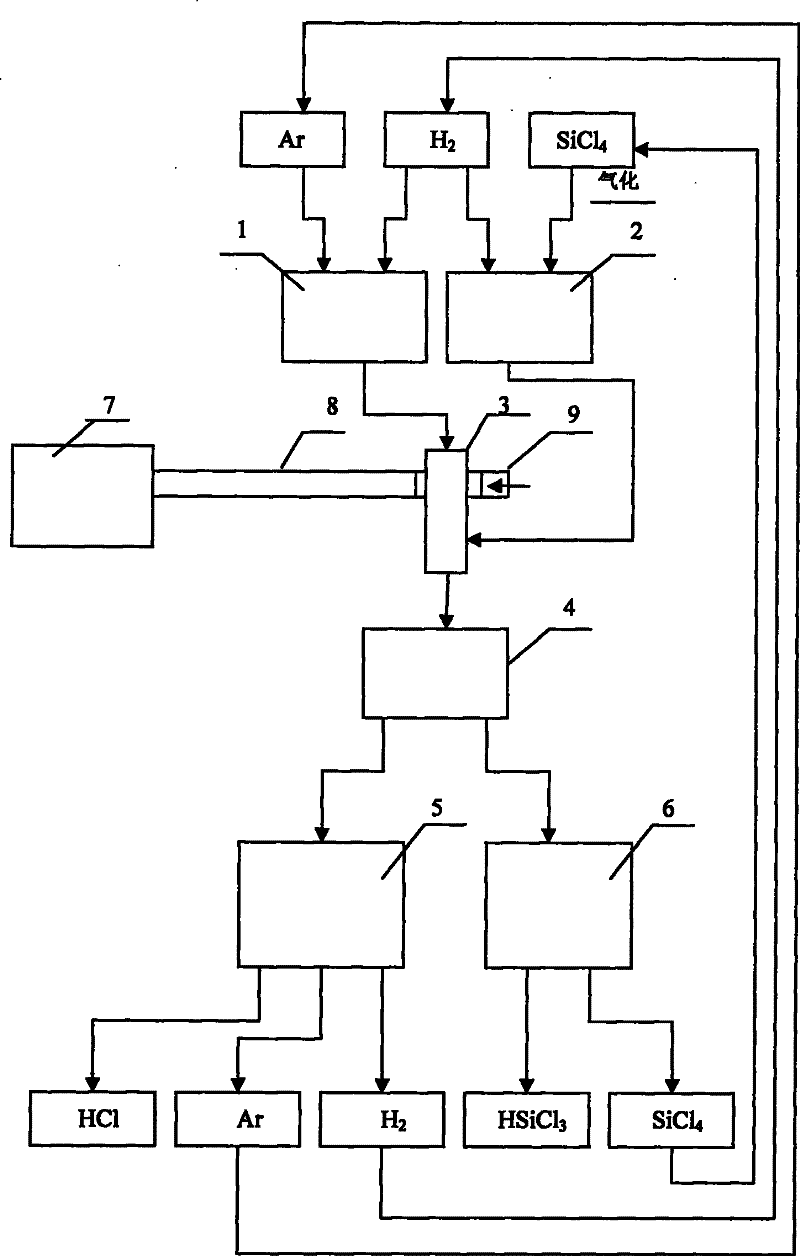

[0046] SiCl 4 For raw materials, refer to figure 1 The system and technological process of the present invention are introduced in detail to produce SiHCl 3 Methods.

[0047]This embodiment produces SiHCl 3 The system consists of the following parts: the first gas control system for arcing gas hydrogen and argon gas intake 1, the adjustment of raw material gas hydrogen and SiCl 4 The second gas control system for intake air 2, plasma reactor 3, condensation separation system for separation of chlorosilane and other gases 4, tail gas treatment system for separation of hydrogen, argon and hydrogen chloride gas 5, various chlorosilanes Separated fractionation separation system 6, microwave generator 7 providing microwaves for the plasma generator, waveguide 8 for microwave transmission and microwave resonator 9, the above-mentioned equipment is conventional equipment used in this profession; apply this figure 1 The system shown is SiCl 4 Production of SiHCl as raw material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com