High-temperature corrosion-resistant vacuum synthesizing furnace and process method thereof

A synthesis furnace and high-temperature furnace technology, applied to chemical instruments and methods, processes below atmospheric pressure, furnaces, etc., can solve the problems of inability to observe the reaction situation, small output, high cost, etc., and achieve safety and environmental protection in the preparation process, and accelerate cooling Crystallization, collection convenience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

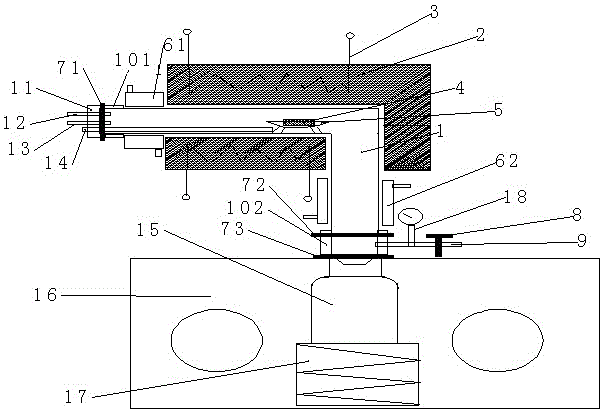

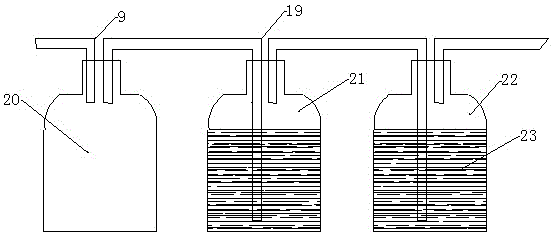

[0031] Please refer to figure 1 A specific embodiment of the present invention provides a high-temperature corrosion-resistant vacuum synthesis furnace, including a tubular high-temperature furnace, a glove box 16, and a gas scrubber. The tubular high-temperature furnace includes a furnace body 2 and a furnace tube 1, and the inner wall of the furnace body 2 is An electric heating device 3 is provided. The electric heating device 3 can be a resistance wire heating device or a silicon carbide rod heating device. The synthesis furnace also includes a temperature controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com