Light-cured cross-linked conductive hydrogel as well as preparation method and application thereof

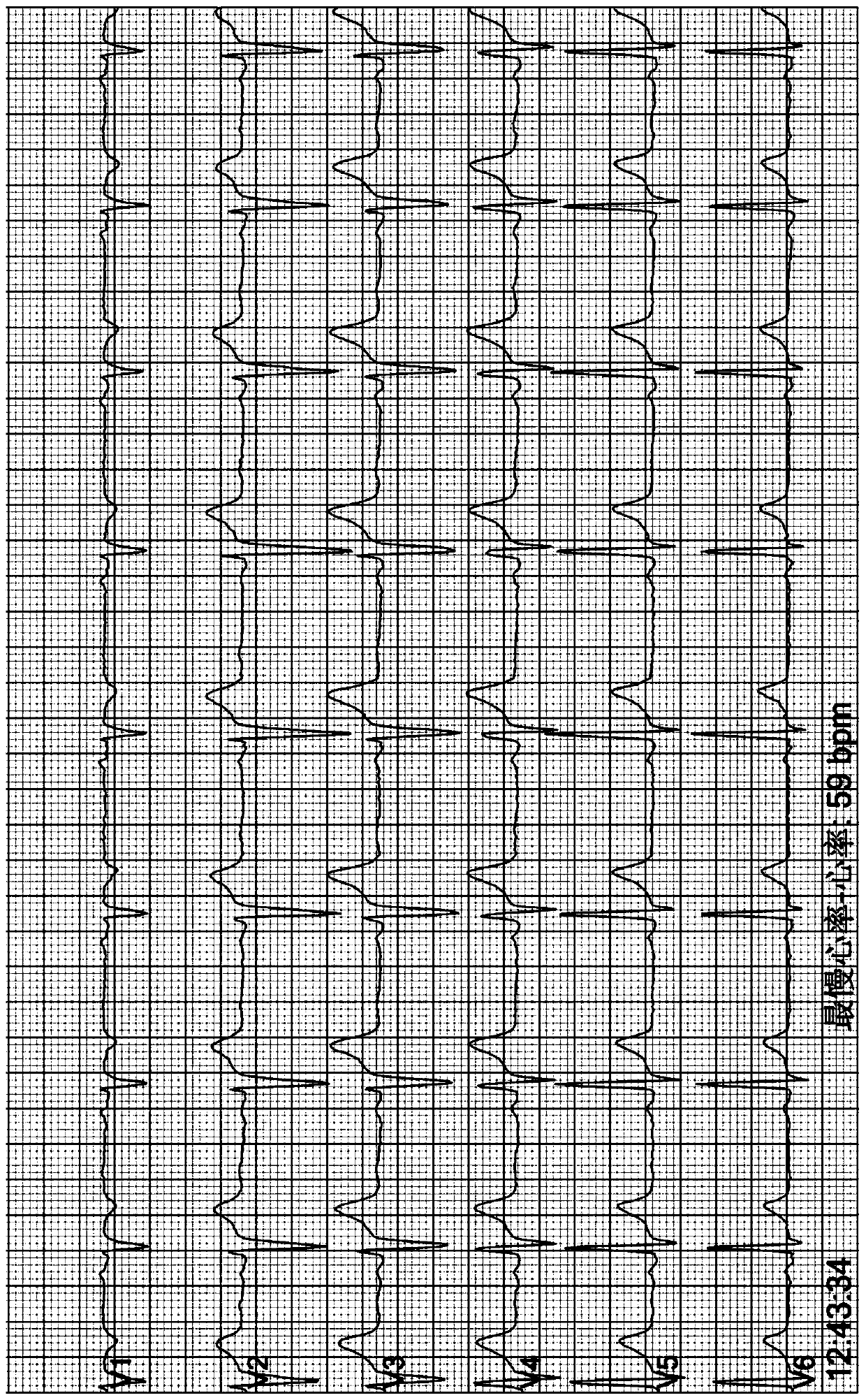

A conductive hydrogel and light-curing technology, applied in applications, sensors, diagnosis, etc., can solve the problems of accurate judgment of diseases that affect the monitoring effect, incomplete reaction of monomers, and unsatisfactory electrical properties, etc., to achieve good contact, The effect of mild conditions and clear waveforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The composition of the light-cured cross-linked conductive hydrogel in this example is shown in Table 1.

[0052] The composition of table 1 embodiment 1 light-cured cross-linked conductive hydrogel

[0053] components parts by mass N-Methylolacrylamide 20 copies Anhydrous Potassium Carbonate 4 parts Potassium hydroxide 0.5 parts N,N'-Methylenebisacrylamide 0.2 parts Glycerol 40 copies potassium chloride 6 servings Lithium magnesium silicate 1 copy 1-[4-(2-Hydroxyethoxy)-phenyl]-2-hydroxy-2-methylacetone 0.5 parts water 50 copies

[0054] The preparation method of the light-cured cross-linked conductive hydrogel in this example is as follows:

[0055] S1: Weigh 20g of N-methylolacrylamide, dissolve it in 20g of water, stir until completely dissolved, and obtain solution A;

[0056] S2: Weigh 0.2g of N,N'-methylenebisacrylamide, dissolve it in 1g of water, stir until completely dissolved, and...

Embodiment 2

[0065] The composition of the photocured crosslinked conductive hydrogel in this example is shown in Table 2.

[0066] The composition of table 2 embodiment 2 light-cured cross-linked conductive hydrogel

[0067] components parts by mass N,N-Dimethacrylamide 15 copies Anhydrous Sodium Carbonate 6 servings N,N'-Methylenebisacrylamide 0.3 parts Glycerol 30 copies Sodium chloride 5 copies Lithium magnesium silicate 1 copy 1-Hydroxycyclohexyl phenyl ketone 0.3 parts 1-[4-(2-Hydroxyethoxy)-phenyl]-2-hydroxy-2-methylacetone 0.2 parts water 60 copies

[0068] The preparation method of the light-cured cross-linked conductive hydrogel in this example is as follows:

[0069] S1: Weigh 15g of N,N-dimethylacrylamide, dissolve it in 30g of water, stir until completely dissolved, and obtain solution A;

[0070] S2: Weigh 0.3g of N,N'-methylenebisacrylamide, dissolve it in 2g of water, stir until completely disso...

Embodiment 3

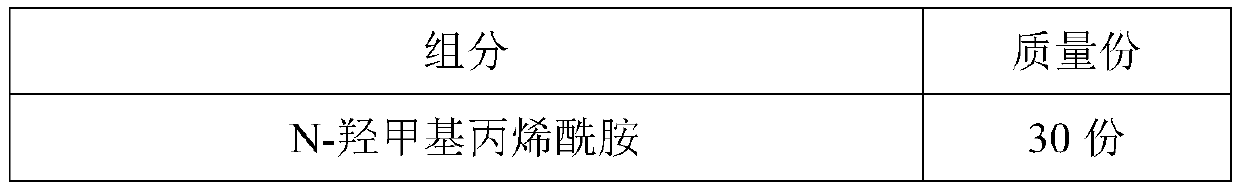

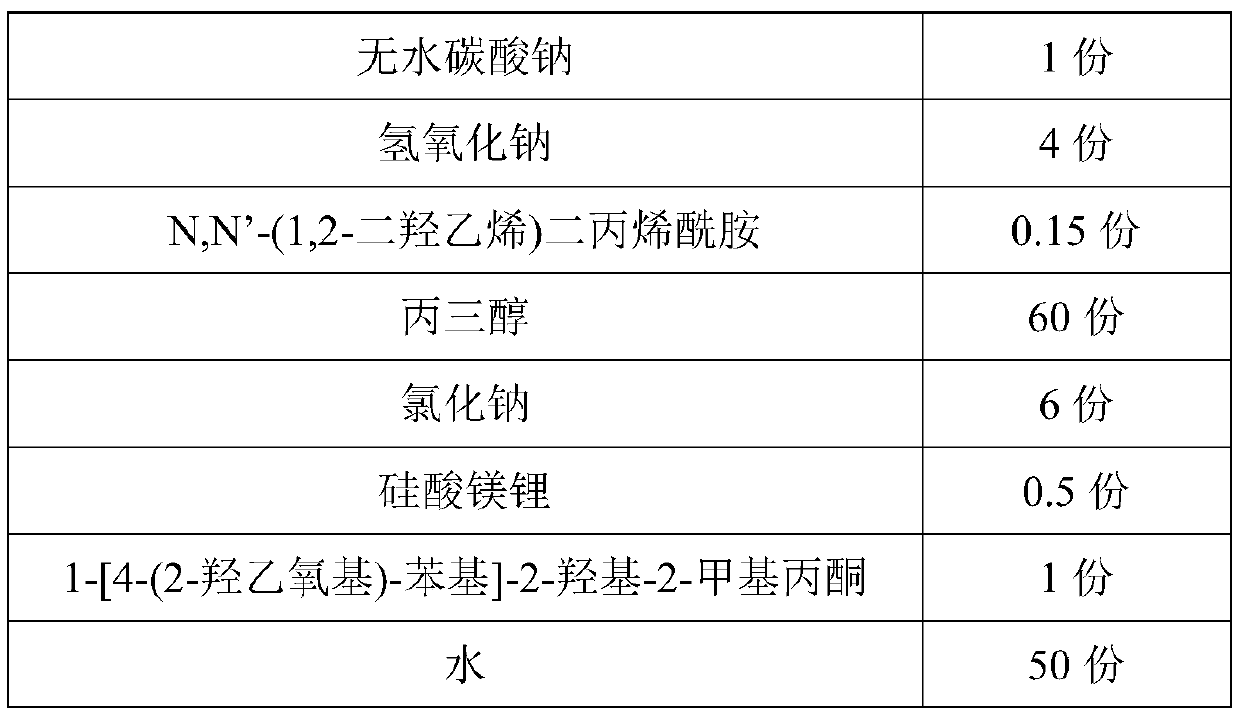

[0079] The composition of the light-cured crosslinked conductive hydrogel in this example is shown in Table 3.

[0080] Table 3 Example 3 Composition of photocuring crosslinked conductive hydrogel

[0081]

[0082]

[0083] The preparation method of the light-cured cross-linked conductive hydrogel in this example is as follows:

[0084] S1: Weigh 30g of N-methylolacrylamide, dissolve it in 30g of water, stir until completely dissolved, and obtain solution A;

[0085] S2: Weigh 0.15g of N,N'-(1,2-dihydroxyethylene) diacrylamide, dissolve it in 1g of water, stir until completely dissolved, and obtain solution B;

[0086] S3: Weigh 4g of sodium hydroxide and 1g of anhydrous sodium carbonate, dissolve in 10g of water, stir until completely dissolved, let the solution stand at room temperature, and obtain solution C;

[0087] S4: Weigh 0.5g lithium magnesium silicate, dissolve in 5g water, stir until completely dissolved, and obtain solution D;

[0088] S5: Slowly pour sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com