Chemically excited combustion process for synthesizing Si3N4/SiC composite powder

A technology of combustion synthesis and composite powder, which is applied in the field of inorganic non-metallic materials to achieve the effects of reducing costs, reducing equipment requirements, and reducing nitrogen pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

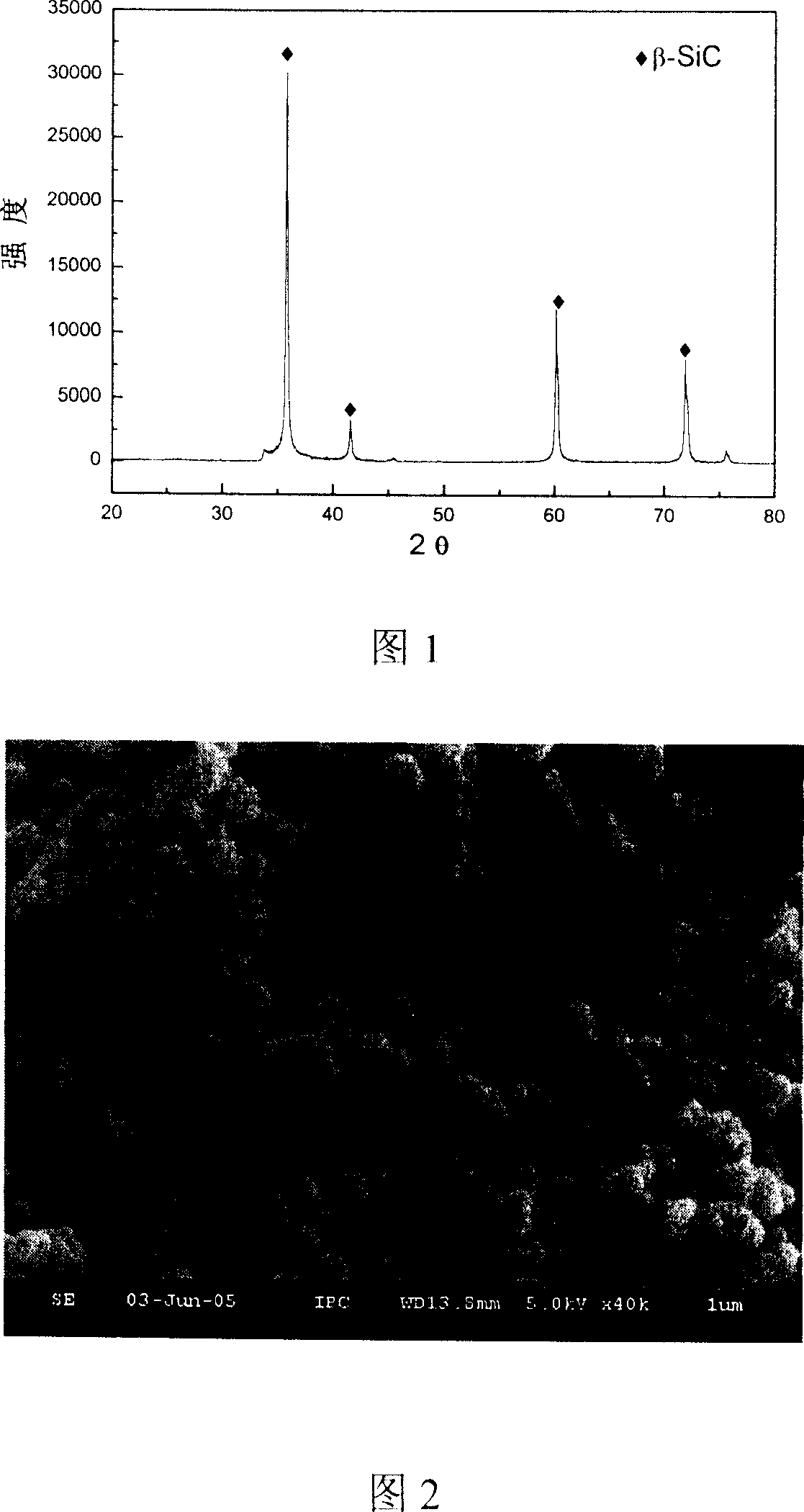

Embodiment 1

[0035] Si powder with an average particle size of 0.5 μm, carbon black with an average particle size of 30 nm, NH 4 Cl and polytetrafluoroethylene are sampled according to the weight ratio of 60:30:5:5, and they are put into the ball milling tank of the vibrating ball mill for 9 hours to make them fully mixed and activated; the mixed and activated material is placed in In a porous graphite crucible, the bulk density is about 0.3-1.0g / cm 3 , place a spiral tungsten wire on the upper layer of the material, the diameter of the tungsten wire is 0.5mm, and put them together into the combustion synthesis reactor; after vacuuming, fill high-purity nitrogen from the bottom of the reactor until the nitrogen pressure reaches 2MPa Pass the spiral tungsten wire with a pulse current of 10-30A to make it generate heat and induce the self-propagating combustion of the raw material powder. After the combustion reaction lasts for 10 minutes, cool to room temperature, then discharge the reactio...

Embodiment 2

[0037] Si powder with an average particle size of 5 μm, carbon black with an average particle size of 20 nm, NH 4 Cl and polytetrafluoroethylene are sampled according to the weight ratio of 70:25:2:3, and the Si powder, carbon black and NH 4 Cl was put into the ball mill jar of planetary ball mill and milled for 5 hours to make it fully mixed, then added polytetrafluoroethylene, and continued to grind for 1 hour; the mixed material was placed in a porous graphite crucible so that the bulk density was about 0.3~1.0g / cm 3 , place a spiral tungsten wire on the upper layer of the material, and put them together into the combustion synthesis reactor; after vacuuming, fill nitrogen gas from the bottom of the reactor to 1MPa; pass the spiral tungsten wire with a pulse current of 12A to make it generate heat and induce The raw material powder is self-propagating combustion, and after the combustion reaction lasts for 30 minutes, cool to room temperature, release the air, and finely g...

Embodiment 3

[0039] Si powder with an average particle size of 44 μm, carbon black with an average particle size of 10 nm, NH 4 Cl and polytetrafluoroethylene are sampled at a weight ratio of 52:31:2:15, put into the ball mill jar of a vibratory ball mill, and ball milled for 4.5 hours to fully mix and activate; the mixed and activated material is placed in In a porous graphite crucible, the bulk density is about 0.3-1.0g / cm 3 , put a spiral tungsten wire on the upper layer of the material, the diameter of the tungsten wire is 0.5mm, and put them together into the combustion synthesis reactor; after vacuuming, fill the argon gas from the bottom of the reactor to 3MPa; put the spiral tungsten wire Pass a pulse current of 12A to make it generate heat and induce the self-propagating combustion of the raw material powder. After the combustion reaction lasts for 15 minutes, cool to room temperature, release the air, and finely grind the product to obtain the reaction product. The reaction prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com