Method for synthesizing Si3N4 powder body and Si3N4/SiC composite powder body

A technology of combustion synthesis and composite powder, which is applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve problems such as complex processes, and achieve the effects of reducing costs, saving inputs, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

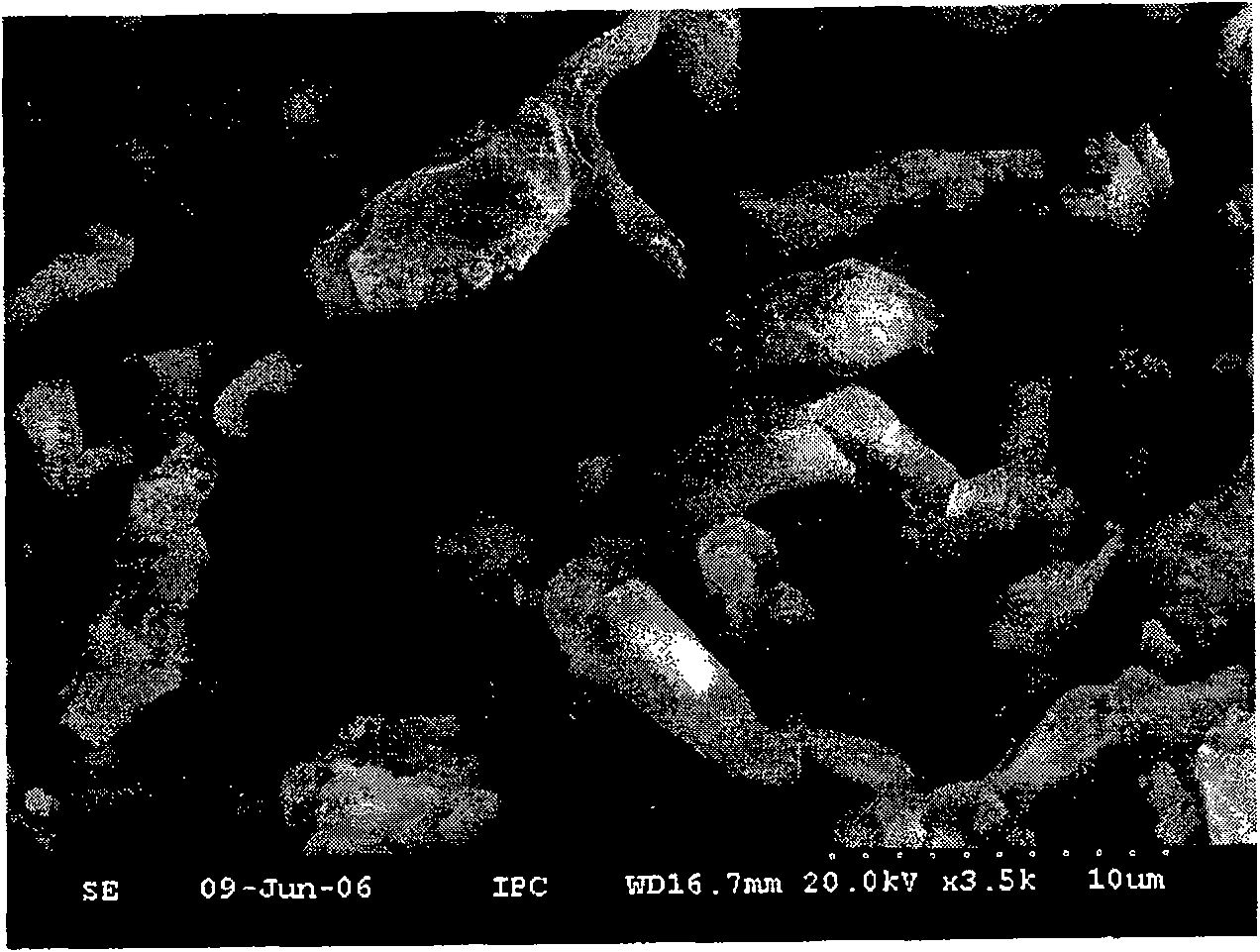

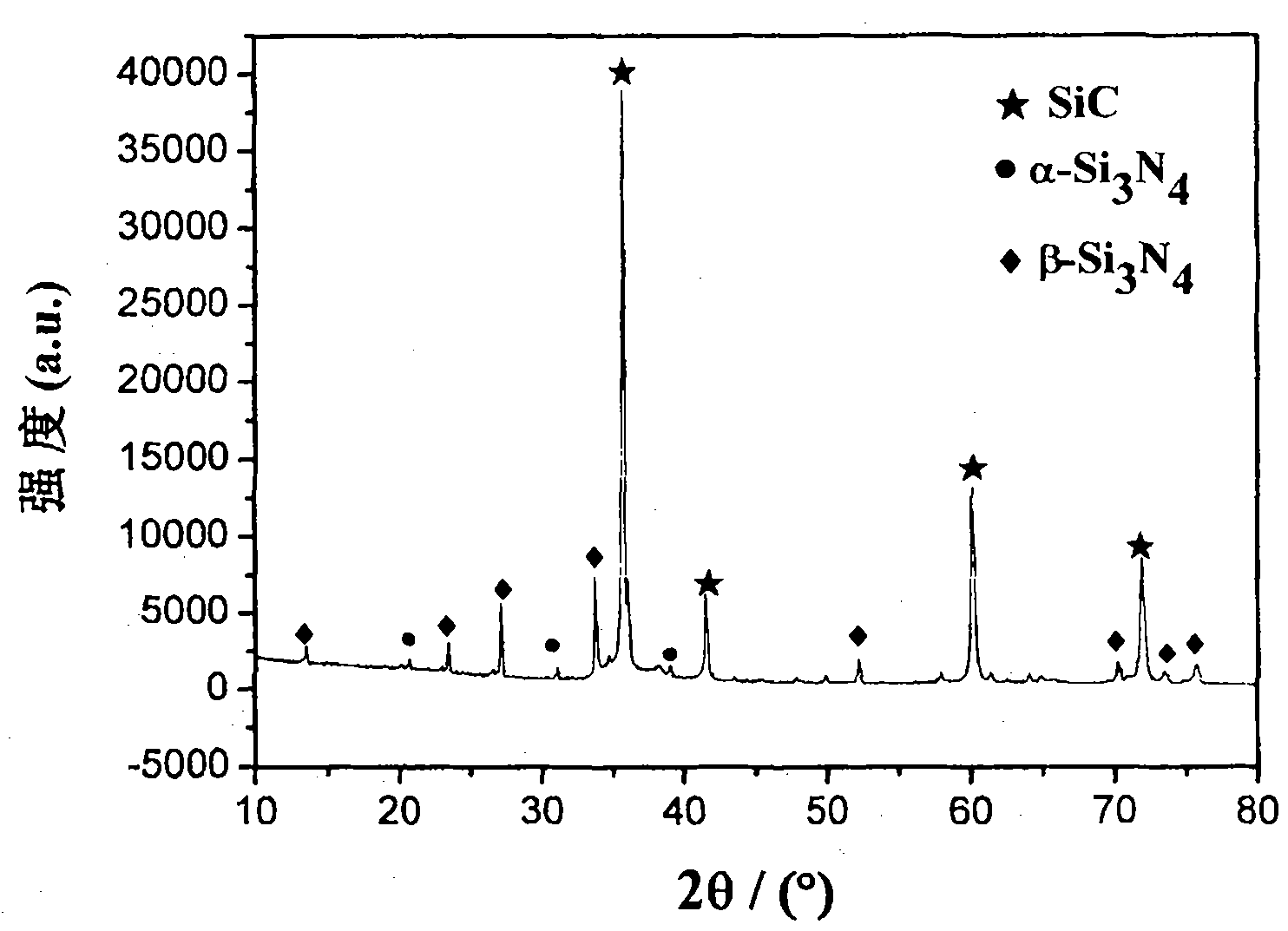

[0031] Take Si powder with an average particle size of 44 μm and Si powder with an average particle size of 10 μm 3 N 4 Powder, NH 4 Cl, NH 4 CO 3 , sampled at a weight ratio of 80:10:5:5, put into a ball mill jar of a vibratory ball mill and mill for 16 hours to fully mix and activate it; place the mixed and activated material in a porous graphite or porous stainless steel crucible , the bulk density is about 0.2 ~ 1.0g / cm 3, place a spiral tungsten wire on the upper layer of the material, and place the crucible in an environment with good air circulation; pass the spiral tungsten wire with a pulse current of 12A to induce heating of the raw material powder mixture by local heating and self-propagating combustion synthesis After the reaction, the combustion reaction lasts for 60 minutes, the block-shaped product synthesized by the reaction combustion can be obtained, and the product is ground. The reaction product was analyzed by XRD with the D / MAX-IIB X-ray diffraction ...

Embodiment 2

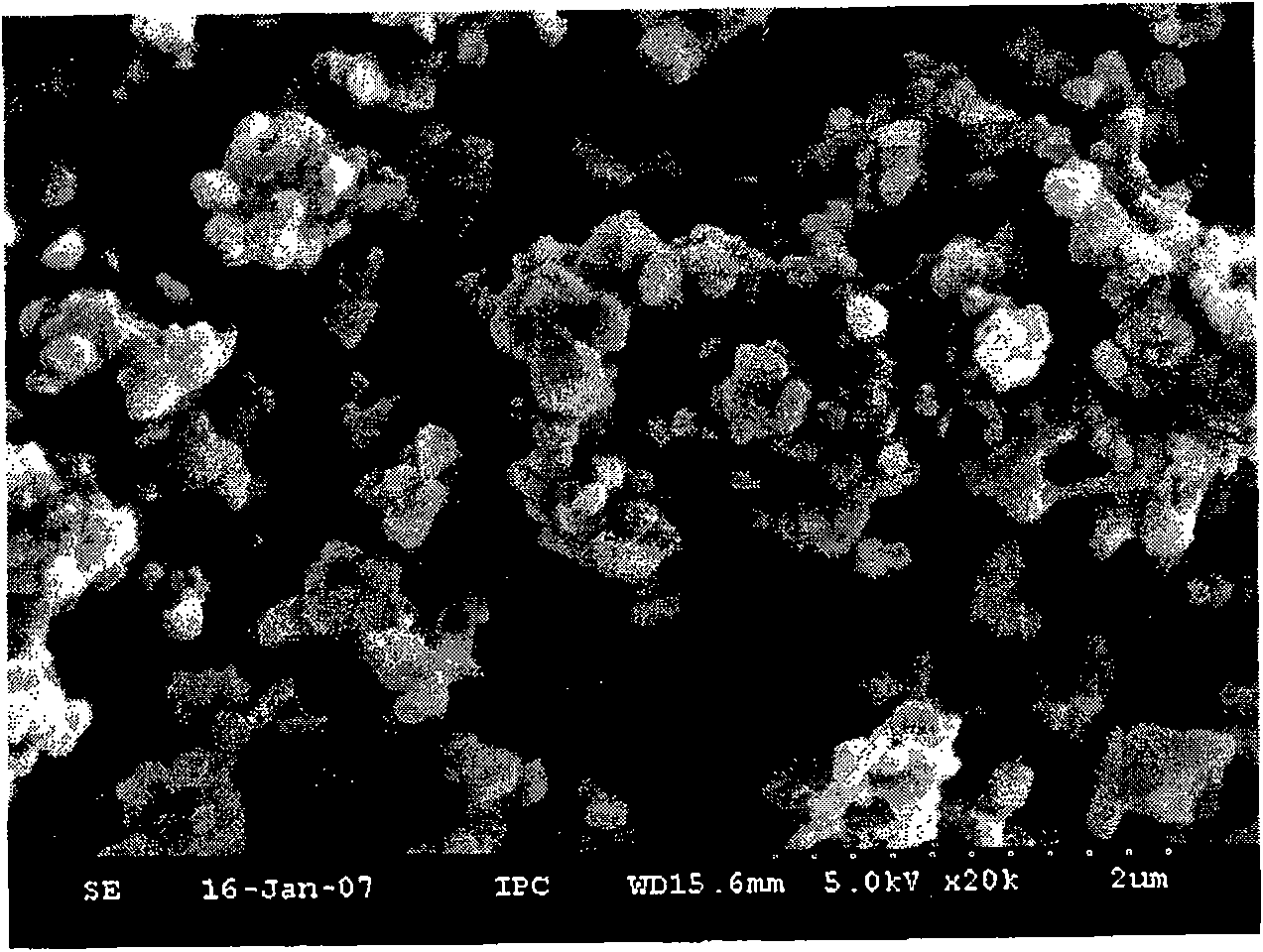

[0033] Take Si powder with an average particle size of 0.5 μm, carbon black with an average particle size of 30 nm, and Si powder with an average particle size of 20 μm 3 N 4 Powder and NH 4 Cl, sampled at a weight ratio of 70:20:5:5, put them into a ball mill jar of a vibratory ball mill and mill them for 30 hours to fully mix and activate them; place the mixed and activated materials in porous graphite or porous graphite In a stainless steel crucible, its bulk density is about 0.2-1.0g / cm 3 , and then place the porous graphite or porous stainless steel crucible in an air atmosphere environment. After a few minutes, the raw material powder undergoes a self-propagating combustion synthesis reaction. After the combustion reaction lasts for 90 minutes, it is cooled to room temperature, and the reaction combustion synthesis reaction can be obtained. Lumpy product, grind the product. The reaction product carries out phase analysis with the D / MAX-IIB type X-ray diffraction analy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com