Molybdenum superfine powder and preparation method thereof

A technology of ultra-fine powder and powder, which is applied in the direction of nanotechnology, nanotechnology for materials and surface science, nanotechnology, etc., can solve the limitation of industrial production of molybdenum ultrafine powder and uneven particle size distribution of powder , ultra-fine molybdenum powder equipment requirements and other issues, to achieve the effect of reducing product agglomeration, enhanced fluidity, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A molybdenum ultrafine powder and a preparation method thereof. Mix 25.2-38.7wt% of sodium molybdate powder, 7.5-11.3wt% of metal aluminum powder and 50-67.3wt% of halide powder to prepare mixed powder; place the mixed powder Put it into a box-type electric furnace, raise the temperature to 600-700°C under the condition of argon atmosphere and a heating rate of 5-8°C / min, and keep it warm for 2-4 hours to obtain a pretreatment powder; then the pretreatment powder Put the body into a nitric acid solution with a concentration of 2-4mol / L and soak for 3-5 hours, filter to obtain the filtered mixture, wash the filtered mixture repeatedly with deionized water until the cleaning solution is neutral, and then heat it at 110°C Drying under conditions for 6 to 12 hours can obtain molybdenum superfine powder.

[0029] The halide powder described in this embodiment is a mixture of sodium chloride, potassium chloride and sodium fluoride; wherein: sodium chloride is 20 to 40 wt%, p...

Embodiment 2

[0032] A molybdenum ultrafine powder and a preparation method thereof. Mix 19.4-25.2wt% of sodium molybdate powder, 5.6-7.5wt% of metal aluminum powder and 67.3-75wt% of halide powder to prepare mixed powder; put the mixed powder into In a box-type electric furnace, the temperature is raised to 700-850°C under the condition of an argon atmosphere and a heating rate of 5-8°C / min, and the temperature is kept for 2-4 hours to obtain a pretreated powder; then the pretreated powder is Soak in a nitric acid solution with a concentration of 2-4mol / L for 3-5 hours, filter to obtain a filtered mixture, wash the filtered mixture repeatedly with deionized water until the cleaning solution is neutral, and then heat it at 110°C Drying under high temperature for 6-12 hours, the molybdenum superfine powder can be obtained.

[0033] The halide powder described in this embodiment is sodium chloride.

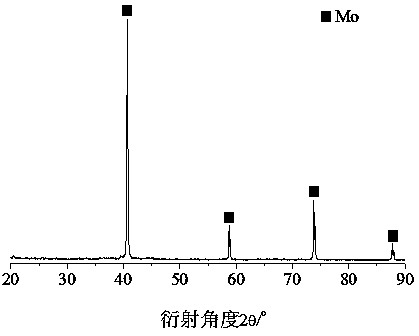

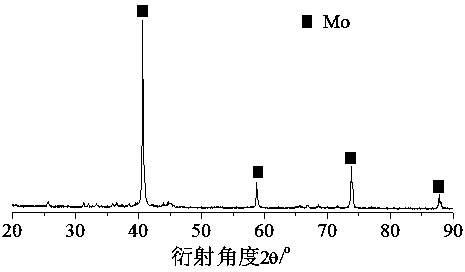

[0034] The XRD spectrum of a kind of molybdenum ultrafine powder prepared in the present em...

Embodiment 3

[0036] A molybdenum ultrafine powder and a preparation method thereof. Mix 25.2-39.6wt% of sodium molybdate powder, 7.5-10.4wt% of metal aluminum powder and 50-67.3wt% of halide powder to prepare mixed powder; place the mixed powder Put it into a box-type electric furnace, raise the temperature to 800-850°C in an argon atmosphere and a heating rate of 2-5°C / min, and keep it warm for 3-5 hours to obtain a pretreated powder; then the pretreated powder Put the body into a nitric acid solution with a concentration of 2-4mol / L and soak for 5-8 hours, filter to obtain the filtered mixture, wash the filtered mixture repeatedly with deionized water until the cleaning solution is neutral, and then heat it at 110°C Drying under conditions for 6 to 12 hours can obtain molybdenum superfine powder.

[0037] The halide powder described in this embodiment is sodium fluoride.

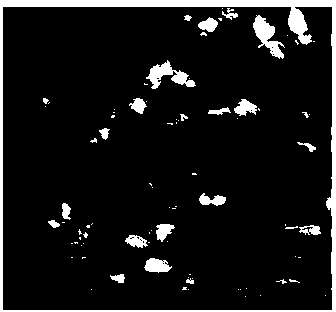

[0038] The ultrafine molybdenum powder prepared in this example has a high purity and a particle size of 0.5-0.9 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com