Preparation device and preparation method of high-purity electronic-grade diiodosilane

A preparation device and electronic-grade technology, which is applied in the direction of halosilane, chemical instruments and methods, silicon compounds, etc., can solve the problems of undiscovered industrial-scale continuous production, long reaction time, and low reaction controllability, and achieve the realization of The effect of large-scale continuous operation, improving the conversion rate of raw materials, and increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The embodiment of the present invention proposes a preparation method of high-purity electronic grade diiodosilane, comprising the following steps:

[0046] Nitrogen replacement: Nitrogen purging replaces the preparation device of high-purity electronic-grade diiodosilane to completely remove water and air;

[0047] Initiate the first step reaction: make a mixture of phenylsilane and oxygen-containing compound catalyst with a volume ratio of 1: (0.01-0.03), and an aromatic organic solvent, and mix the mixture for 50-200h -1 The space velocity is passed into the first reactor through the feeding port for reaction, and generates a top-down phenylsilane layer, an iodophenylsilane layer and a hydrogen iodide layer;

[0048] Control the reaction stability: continuously feed phenylsilane into the first reactor, adjust the flow of phenylsilane at the same time with the flow of the two outlets, and control the interface between the iodophenylsilane layer and the hydrogen iodide...

Embodiment 1

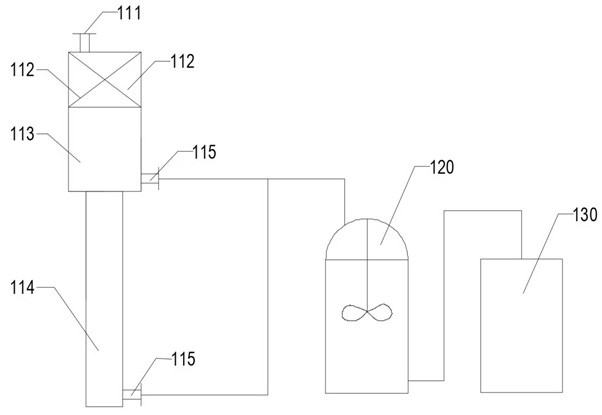

[0053] This embodiment proposes a high-purity electronic-grade diiodosilane preparation device, which includes a first reactor 110 , a second reactor 120 and a vacuum distillation purifier 130 connected in sequence.

[0054] The upper end of the first reactor 110 is provided with a feeding port 111 . The first reactor 110 is divided into a fluidized bed section 112 , an oil phase section 113 and a hydrogen iodide section 114 from top to bottom. The above-mentioned fluidized bed section 112 is provided with a fixed fluidized bed of iodine. The iodine fixed fluidized bed is a catalyst support plate provided with iodine particles. Among them, the oil phase section 113 is used to place an iodophenylsilane layer, or part of the phenylsilane layer (including unreacted phenylsilane, a small amount of catalyst and aromatic organic solvent that initiates the reaction), and the hydrogen iodide section 114 is used to place Hydrogen iodide layer. Due to the first step reaction of Ph-Si...

Embodiment 2

[0066] The present embodiment also proposes a preparation method of high-purity electronic grade diiodosilane, which comprises the following steps:

[0067] Nitrogen replacement: Nitrogen purging replaces the preparation device of high-purity electronic-grade diiodosilane to completely remove water and air;

[0068] Initiate the first step reaction: 10L of phenylsilane, 0.1L of oxygen-containing compound catalyst (acetone), and 12L of aromatic organic solvent (benzene) are made into a mixed solution, and the mixed solution is heated for 50h -1 The space velocity is passed into the first reactor through the feed port for reaction, and generates a top-down phenylsilane layer, an iodophenylsilane layer and a hydrogen iodide layer; in the present embodiment, the oxygen-containing compound catalyst is acetone, In other embodiments, the above-mentioned oxygen-containing compound catalyst can also be ethanol or ethyl acetate, or a mixture of at least two of acetone, ethanol and ethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com